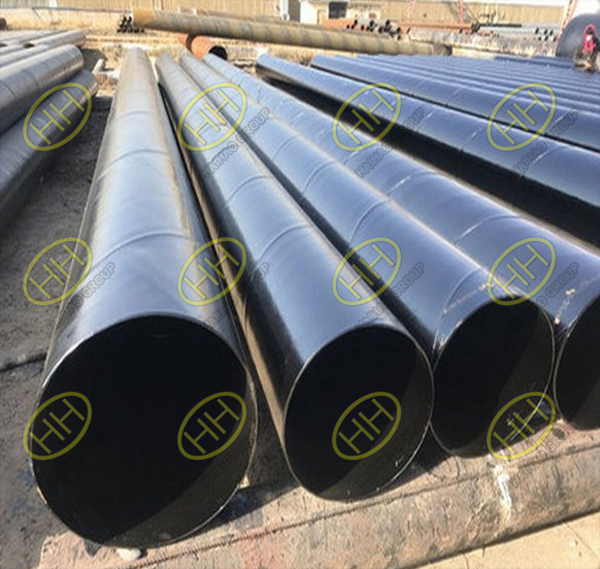

Advanced maintenance methods for thick-walled steel pipes

With the continuous development of the Chinese economy and the emphasis on the energy industry, long-distance oil and gas pipelines have become crucial for ensuring energy security. In the construction of anti-corrosion measures for oil and gas pipelines, the surface treatment of steel pipes is a key factor in determining the service life of the pipeline. It is a prerequisite for the firm bonding of the anti-corrosion layer with the steel pipe. According to research institutions, the service life of the anti-corrosion layer depends not only on factors such as the type of coating, coating quality, and construction environment but also significantly on the surface treatment of the steel pipe, accounting for approximately 50% of the impact on the anti-corrosion layer’s lifespan. Therefore, it is essential to strictly follow the specifications for the surface of the steel pipe, continually explore and summarize, and improve the surface treatment methods of thick-walled steel pipes.

Maintenance Methods for Thick-Walled Steel Pipes:

Manual Rust Removal: Manual tools such as wire brushes are primarily used to polish the surface of the steel, removing loose or lifted oxide scales, rust, welding slag, etc. Manual rust removal can achieve Sa2 level cleanliness, while power tool rust removal can achieve Sa3 level cleanliness. If the steel surface has firmly attached oxide scales, manual rust removal may not be sufficient to meet the anchor pattern depth required for anti-corrosion construction.

Acid Pickling: Acid pickling is generally carried out using chemical and electrolytic methods. For pipeline anti-corrosion, only chemical acid pickling is employed, which can remove oxide scales, rust, and old coatings. Sometimes it can be used as a post-treatment after sandblasting rust removal. Although chemical cleaning can achieve a certain degree of cleanliness and roughness, its anchor pattern is shallow, and it can easily cause environmental pollution.

As an expert in the field of pipeline systems, Haihao Group is proficient in the production and maintenance of various pipeline supplies. If your project requires supporting products for pipeline systems, please feel free to contact us.