Difference between socket welding and butt welding

There are various connecting types for the steel pipes,pipe fittings and flanges: socket weld,butt weld,threaded and so on.Socket welding and butt welding are the quite popular of those.However,you might be confused about which one would be best for your pipeline system,since both of them seem to have their own pros and cons.Therefor,we have taken the responsibility of drawing up a comparison between them.

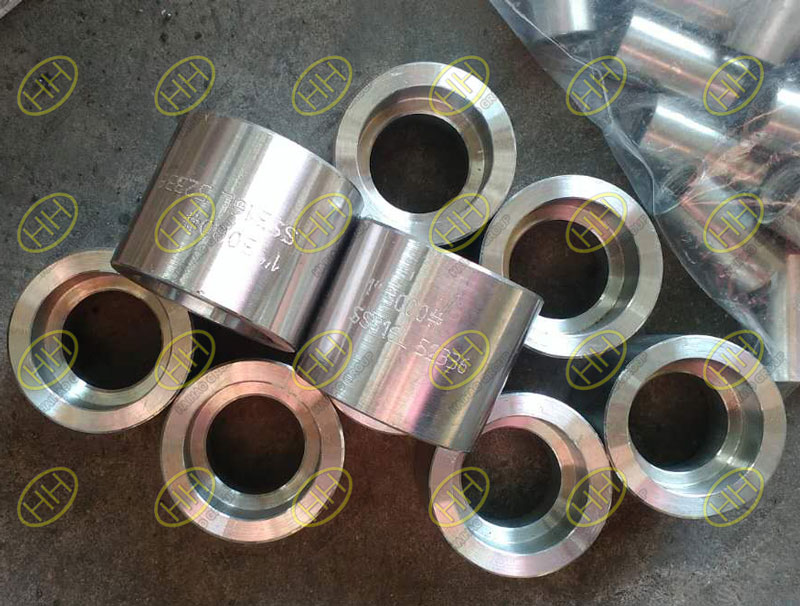

Socket welding refers to the pipe into the valve body for welding,mostly used for 2″ below the carbon steel pipe, stainless steel pipe welding.

Butt welding refers to the use of resistance heat along the whole face of the two workpieces together at the same time welding,is widely used in the workpiece welding.

Haihao Group has been producing butt welding and socket welding pipeline products for a variety of applications since 1982,our products contain steel pipes(seamless steel pipes,API 5L line pipe,welded pipe,galvanized pipe,oil casting pipe,boiler tube,precision steel pipe,coated and insulated piping),pipe fittings(pipe elbow,tee,reducer,cap,bend,coupling,nipple,cross etc) and flanges(weld neck flange,blind flange,socket weld flange,threaded flange,slip on flange,lap joint flange,orifice flange,spectacle flange,anchor flange,reducing flange,tube sheet,flange-olet etc).

If you need,please feel free to contact me.Email:sales@haihaogroup.com