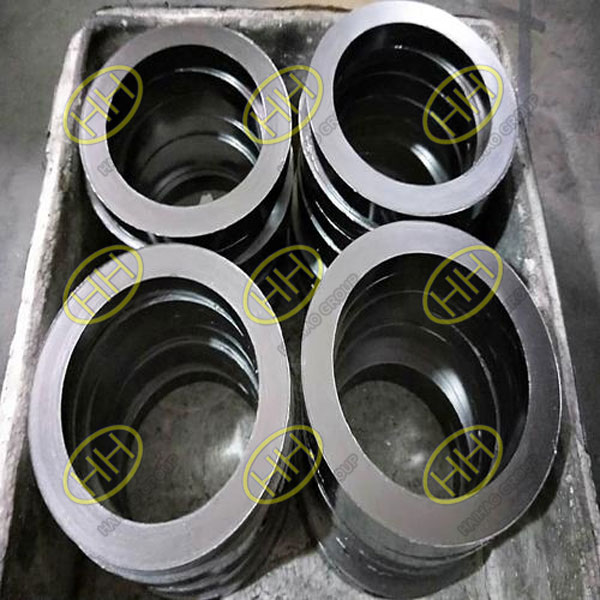

Introduction to IX Seal Ring

The IX Seal Ring is a high-performance metal-to-metal sealing component used in compact flanges (EN ISO 27509, API 6A). It is widely applied in high-pressure, high-temperature, and subsea environments, providing a secure and leak-proof connection.

Shape and Design

The IX Seal Ring has a specialized profile designed for self-energizing sealing. When pressure increases, the ring deforms slightly, enhancing the seal between the flange faces. This pressure-activated sealing mechanism makes it ideal for extreme conditions.

Key Features

Self-Energizing Effect – As internal pressure rises, the seal tightens automatically.

Metal-to-Metal Contact – Ensures durability, preventing gasket blowout.

Corrosion & Temperature Resistance – Commonly made from Stainless Steel, Duplex, or Inconel, it withstands harsh environments.

Reduced Bolt Load Requirement – Compared to traditional gaskets, it enables smaller, lighter flange designs while maintaining strength.

High Pressure Resistance – Suitable for systems exceeding 10,000 PSI, often used in offshore, oil & gas, and subsea pipelines.

Applications

The IX Seal Ring is commonly used in:

Offshore and Subsea Piping Systems

High-Pressure Oil & Gas Pipelines

Chemical and Power Plants

Industrial High-Temperature Systems

The IX Seal Ring is a cutting-edge sealing solution engineered for compact flange systems in high-pressure and high-temperature environments. Its self-energizing design, metal-to-metal contact, and corrosion resistance make it the preferred choice for industries where sealing reliability is critical.For more information,please feel free to contact us email: sales@haihaogroup.com