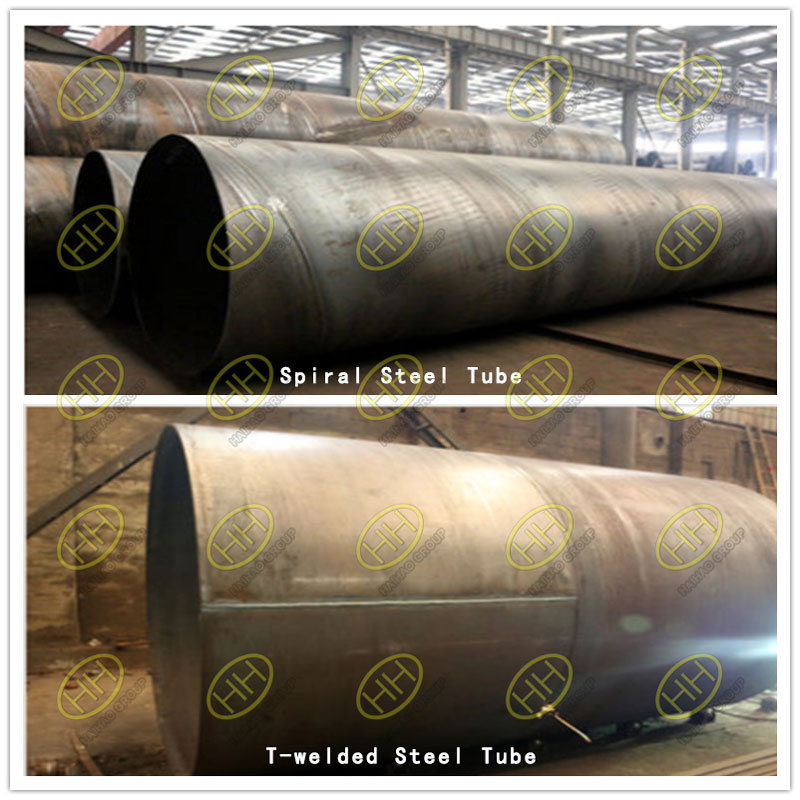

What is the difference between spiral steel tube and t-welded steel tube?

Spiral steel tube and T-welded steel tube are basically the same raw materials used for steel pipe, but they are very different in the production process.

Spiral steel pipe: the spiral seam steel pipe is made by automatic double silk and double submerged arc welding process, which is made of strip steel coil as raw material and often formed by warm extrusion.

T-shaped steel plate welding tube: the t-shaped welding (two cylinder butt welding can weld a circle longitudinal weld, and the cylinder itself the intersection of a horizontal weld forming tee joint), it can produce more than 4000 diameter, wall thickness of 6-100 mm steel pipe, steel coil tube is mainly used in the model, or the thickness of the thicker in the industry, sometimes there will be two weld, why will appear this kind of circumstance, mainly because of raw materials and equipment processing problems. The main problem of making t-shaped welded coil pipe is welding. As long as it can pass the inspection of flaw detection, it can carry out the requirements related to delivery, which are broader than other products. However, this does not affect his use of t-welded steel coil and spiral steel pipe is widely used in petroleum, chemical industry, natural gas transportation, piling and urban water supply, heating, gas supply and other projects.

The price of spiral steel pipe and steel plate coil: the price of spiral steel pipe and the same type of steel plate coil is lower than steel plate coil.