Understanding Pipe Thread Types and Standards: NPT, BSP, and More

When it comes to industrial pipe fittings and connections, understanding thread standards is essential. Pipe threads play a critical role in ensuring secure, leak-proof connections in piping systems across oil & gas, chemical processing, water treatment, and power generation industries. In this article, we explore the most commonly used pipe thread types—NPT, BSP, and others—highlighting their differences, applications, and sealing capabilities.

1.American Pipe Threads (ANSI/ASME Standards)

NPT (National Pipe Taper)

Thread type: Tapered

Standard: ASME B1.20.1

Seal: Threaded metal-to-metal with sealant (e.g., PTFE tape)

Application: Widely used in industrial piping systems in North America

NPT threads are designed to provide a pressure-tight seal when mated with a fitting of the same type. The taper ensures that the threads compress and create friction to prevent leaks.

NPS (National Pipe Straight)

Thread type: Straight (parallel)

Seal: Requires gasket or O-ring

Application: Often used in flange connections or mechanical joints

NPS threads are not designed for sealing on their own and typically rely on an external sealing element.

NPTF (National Pipe Taper Fuel / Dryseal)

Thread type: Tapered dry seal

Feature: Designed for pressure-tight seal without additional sealants

Application: Fuel systems, high-precision fluid transfer systems

NPTF threads seal through interference fit, making them ideal for systems where contamination from sealants is a concern.

2.British Pipe Threads (BSP Standard)

BSPT (British Standard Pipe Taper)

Thread type: Tapered

Standard: ISO 7-1

Seal: Thread deformation with sealant

Designation: Marked as “R” (e.g., R1/2)

BSPT threads are similar in function to NPT but differ in thread angle (55° vs. NPT’s 60°), pitch, and form. They are not interchangeable with NPT threads.

BSPP (British Standard Pipe Parallel)

Thread type: Straight (parallel)

Standard: ISO 228

Seal: Requires O-ring or washer

Designation: Marked as “G” (e.g., G1/2)

Commonly used in Europe and Asia, BSPP threads rely on external sealing elements and are widely used in instrumentation and low-pressure applications.

3.Other Thread Types

PT (Pipe Thread – JIS Standard)

Japanese standard thread, formerly used under the PT designation, now aligned with BSPT and marked as “R”. Common in Asian piping systems.

Metric Threads (M and MK)

M: Metric parallel

MK: Metric tapered

Thread angle: 60°

Primarily used in mechanical components, not common for pressure-tight pipe joints.

4.Common Non-Pipe Thread Types

Unified Threads (UN/UNC/UNF)

American mechanical threads, commonly used for bolts, nuts, and fasteners.

UNC = Coarse thread, UNF = Fine thread.

Metric Threads (M-series)

International mechanical standard.

Example: M8 × 1.25 (8mm outer diameter, 1.25mm thread pitch)

Trapezoidal and Buttress Threads

Designed for power transmission or heavy load-bearing.

Examples: Trapezoidal screw threads (Tr), buttress threads for high axial loads.

Why Understanding Thread Standards Matters

For manufacturers, suppliers, and engineers, identifying the correct thread type is essential to ensuring safety, compatibility, and performance. Incorrect thread matching can lead to leaks, system failure, or safety hazards.

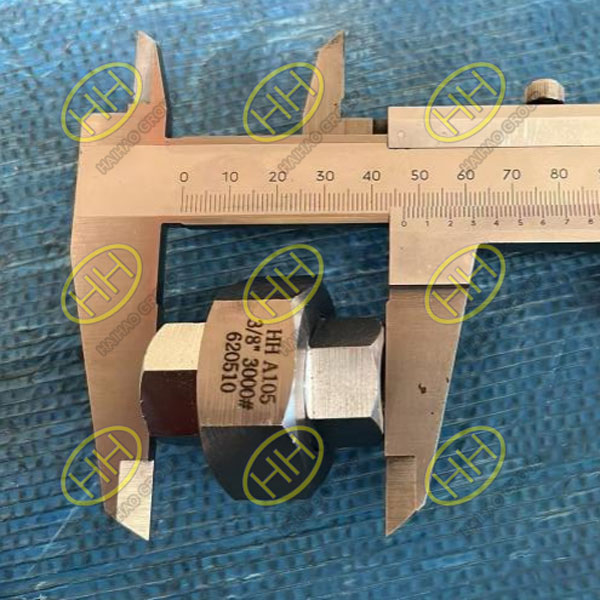

At Haihao Group, we specialize in producing a wide range of threaded pipe fittings, including NPT threaded fittings, BSP threaded fittings, and custom thread types according to client specifications. Whether you’re sourcing pipe elbows, tees, unions, or custom-machined parts, we ensure full compliance with international standards such as ASME, DIN, BS, and ISO.

Need Threaded Pipe Fittings for Your Project?

Haihao Group offers:

- NPT, BSPT, BSPP, UN, and custom thread types

- Full material traceability and inspection reports (PMI, UT, MT)

- Support for high-pressure, corrosive, and nuclear-grade applications

Contact us today to request a quote or learn more about our capabilities.