Causes of corrosion in open-loop EGCS piping systems

Open-Loop Exhaust Gas Cleaning Systems (EGCS) are widely used on ships to reduce sulfur emissions. However, these systems can cause significant corrosion in piping systems due to various factors. Below are the main causes of corrosion in open-loop EGCS piping systems:

1.Chemical Corrosion

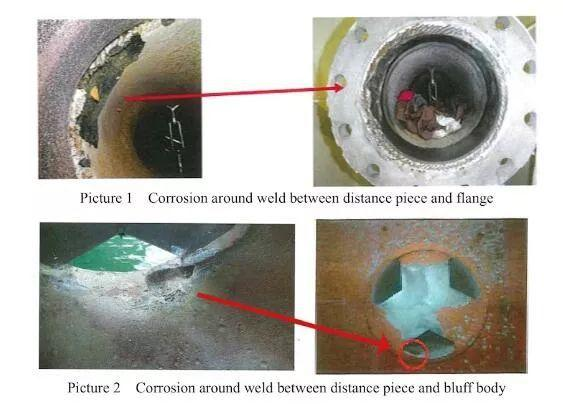

In open-loop EGCS, seawater reacts with sulfur compounds present in exhaust gases, producing highly acidic substances. These acidic substances can lead to severe chemical corrosion in the piping system. The weld seams are particularly vulnerable, as welding processes can create defects such as pores and slag inclusions, making these areas more susceptible to corrosion.

2.Electrochemical Corrosion

Seawater acts as an electrolyte solution, and when it comes into contact with the piping system, it forms a galvanic cell, resulting in electrochemical corrosion. In this process, the metal in the piping loses electrons and forms ions that enter the seawater, causing corrosion. Additionally, the presence of different metals within the piping system can create galvanic corrosion, accelerating the rate of corrosion.

3.Erosion Corrosion

The flow of seawater and exhaust gases within the open-loop EGCS system can lead to erosion corrosion on the inner walls of the piping. This flow wears away the protective layer on the inner surface of the piping, making it more prone to corrosion. Areas such as elbows and tees in the piping system are particularly affected due to the higher flow velocity, which intensifies erosion corrosion.

4.Impact of Temperature and Pressure

The temperature and pressure of seawater and exhaust gases in the piping system can also influence corrosion. Higher temperatures accelerate chemical reactions, increasing the rate of corrosion. Similarly, higher pressures intensify the erosive action of seawater and exhaust gases on the inner walls of the piping, further speeding up the corrosion process.