Duplex stainless steel-Evaluation of Metal Harmful Phase

Duplex stainless steel (DSS) refers to stainless steel in which ferrite and austenite account for about 50% respectively. Generally, the content of less phase also needs to reach 30% at least. When the content of C is low, the content of Cr is 18% ~ 28%, and the content of Ni is 3% ~ 10%. Some steels also contain Mo, Cu, Nb, Ti, N and other alloy elements.

This kind of steel has the characteristics of both austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and toughness, no room temperature brittleness, significantly improved intergranular corrosion resistance and welding performance. At the same time, it also maintains the 475 ℃ brittleness, high thermal conductivity and Superplasticity of ferritic stainless steel. Compared with austenitic stainless steel, it has high strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel saving stainless steel. It is often used in heat exchangers, chillers and devices that are resistant to seawater, high temperature and concentrated nitric acid, such as oil refining, chemical fertilizer, papermaking, petroleum and chemical industry.

A particularly important experiment to judge whether the material of duplex stainless steel is qualified is the evaluation of metal harmful phase, which is an important data to judge whether the material of duplex stainless steel is qualified. Let’s introduce it to you.

Duplex (austenitic-ferritic) stainless steels are susceptible to the formation of intermetallic compounds during exposures in the temperature range from approximately 600 to1750°F (320 to 955°C). The speed of these precipitation reactions is a function of composition and thermal or thermomechanical history of each individual piece. The presence of these phases is detrimental to toughness and corrosion resistance.

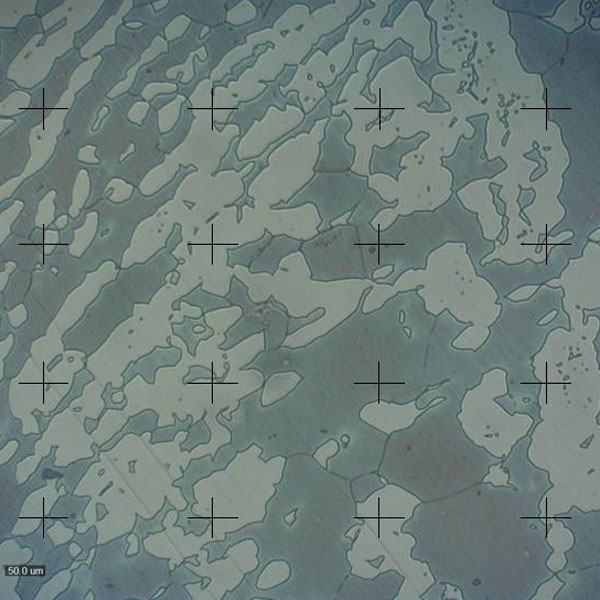

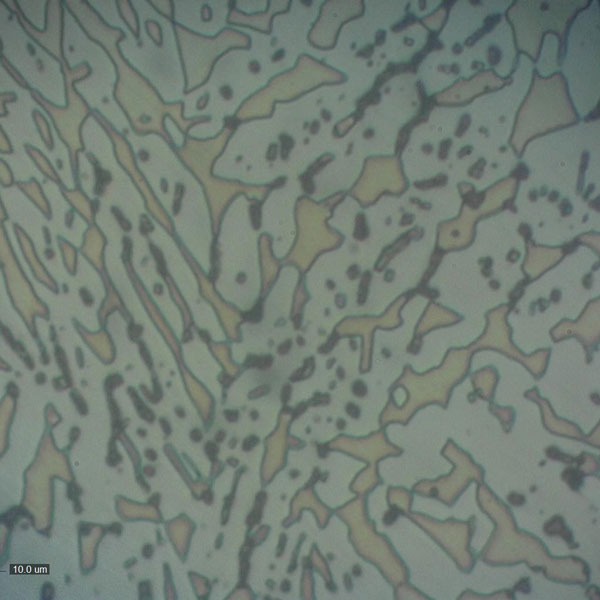

Then how can we determine whether it is qualified? Please check the micrograph pictures.

These are qualified ones without metal compounds.

These are unqualified ones with a large amount of metal compounds.

Through the above comparison, it can be seen that there are many harmful metal phases in unqualified products, and it is very obvious.

So when you buy duplex stainless steel products, you should polish your eyes and choose a reliable supplier.

If you need duplex stainless steel products, please contact us.