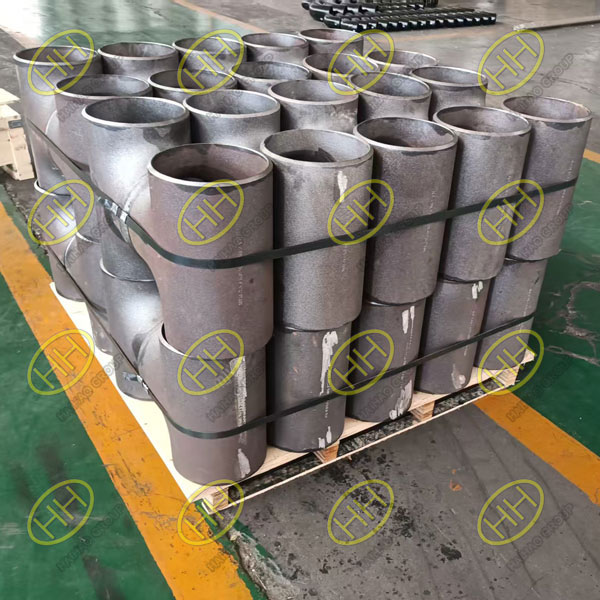

Haihao Group delivers premium seamless equal tees to Italy

As a leading industrial pipe fitting manufacturer integrating industry and trade capabilities, Haihao Group recently completed a strategic order for seamless equal tees for an Italian client in the energy sector. This case study highlights our expertise in delivering tailored solutions that meet rigorous international standards and application-specific demands.

Project Overview: Tailored Solutions for European Energy Infrastructure

The Italian client, a prominent player in renewable energy systems, required 8 distinct seamless equal tee specifications to integrate into a biogas pipeline network. The order included:

| Specification | Size (DN/mm) | Wall Thickness | Material | Standard |

|---|---|---|---|---|

| Seamless Equal Tee | 50-600 (2″-24″) | STD | ASTM A234 WPB | ASME B16.9 |

| Seamless Equal Tee | 60.3/76.1 | 2.9mm | P265GH | EN 10253-2 |

Key Customization Requirements:

- Dual certification for ASME B16.9 (USA) and EN 10253-2 (EU)

- -10°C impact testing to comply with European cold-climate regulations

- Laser-engraved lot tracking for full supply chain visibility

Quality Assurance Protocols

Every tee underwent 7-stage quality control:

- Visual Inspection: 100% defect-free surfaces verified under 500W LED magnification.

- Dimensional Audit: CNC coordinate measuring machines (CMM) confirmed ±0.8mm tolerance.

- Chemical Analysis: Spectrometers validated A234WPB (carbon steel) and P265GH (European pressure vessel steel) compositions.

- Mechanical Testing:

- Tensile Strength: 375-500 MPa (ASTM A234)

- Charpy V-Notch: 27J impact energy at -10°C

- Hydrostatic Pressure Test: Sustained 30MPa for 15 minutes (1.5x rated pressure)

- PMI Certification: Material traceability linked to mill heat codes

- Packaging Compliance: VCI paper wrapping and shock-absorbent crating for maritime transport

Why This Order Matters for Global Clients

Dual Standard Compliance:

- ASME B16.9 ensures compatibility with North American pressure equipment.

- EN 10253-2 meets European Union pressure directive requirements.

Cold-Weather Performance:

The -10°C impact test guarantees durability in Scandinavian and Alpine climates, critical for biogas pipelines operating in subzero temperatures.

Material Versatility:

A234WPB: Ideal for hydrocarbon service (oil/gas pipelines).

P265GH: Engineered for high-temperature steam systems (up to 400°C).

Haihao Group’s Competitive Edge

- Vertical Integration: In-house steel mills → forging → machining → finishing.

- Certification Portfolio: ISO 9001, API 5L, PED 2014/68/EU, and AD2000-W0.

- Global Logistics: 15 strategically located warehouses enable JIT delivery to 92 countries.

- Custom Engineering: 3D CAD modeling and FEA simulation for complex geometries.

Applications of Seamless Equal Tees

Haihao Group’s tees are engineered for:

- Oil & Gas: Flow distribution in gathering systems and refineries.

- Power Generation: Steam header networks in thermal plants.

- Chemical Processing: Corrosive fluid handling in FCC units.

- Marine Engineering: Ballast and bilge systems in LNG carriers.

Partner with Haihao Group for Pipeline Excellence

This Italian order underscores our ability to deliver custom-engineered fittings that bridge continental standards and environmental demands. With 40 years of industry leadership, we combine technical mastery with customer-centric innovation. If you want to know more about pipeline products,please feel free to contact us,email:sales@haihaogroup.com