The advantages and disadvantages of socket welded fittings

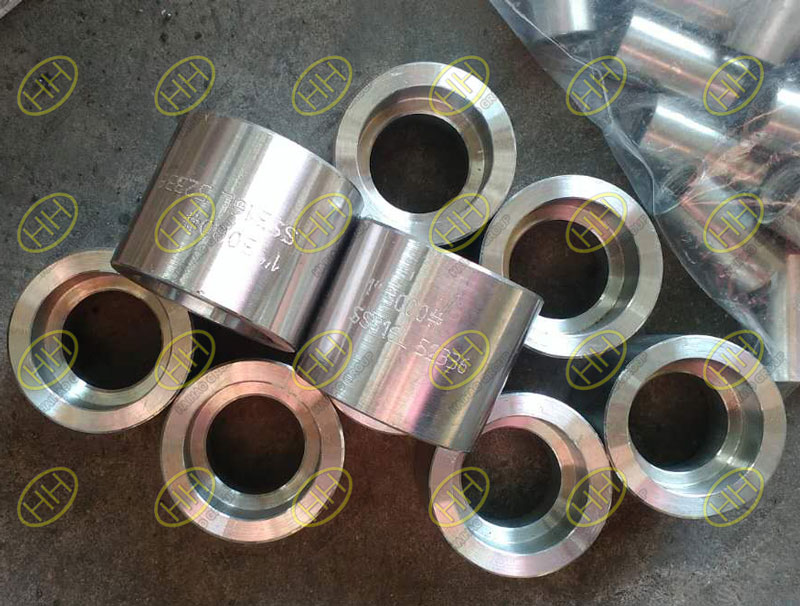

Socket welded fitting is another kind of welded fitting compared with butt-welded fitting. The diameter of socket welded fitting is usually the small diameter-2 inches and below. The socket welded fittings are welded by fillet weld, which is more suitable for high structural strength pipeline environment.

Socket welded fittings have their own advantages and disadvantages,as shown below:

The advantages of socket welded fittings:

1) No prefabricated groove is required for the pipe connected with socket welded pipe fitting

2) Because the socket welded fittings will also have the function of calibration, there is no need for calibration spot welding during welding.

3) When the socket welded fittings are welded, the welding material will not penetrate into the pipe.

4) Socket welded fittings can replace threaded fittings, which can reduce the risk of pipeline leakage to a certain extent.

5) The operating cost of socket welded fittings is lower than that of butt-welded fittings.Because the using of socket welded fittings does not need to carry out pipe groove prefabrication and groove alignment.

The disadvantages of socket welded fittings:

1) During the welding of socket welded fittings, a certain welding expansion gap should be reserved between the pipe and socket.

2) When the socket welded fittings are welded, cracks and welding gaps in the socket weld will occur, which will reduce the corrosion resistance of the pipeline.

As the professional manufacturer of flanges, fittings, pipes and other pipeline products, our HEIBEI HAIHAO GROUP can produce and supply various types and sizes of socket welded fittings. If you have any need, please feel free to contact us.Email:sales@haihaogroup.com