Type of pipeline coating

A pipeline coating is a cost effective and viable solution to maintain pipelines’ integrity. Coatings are typically applied to counter the negative effects of corrosion on pipeline operation, capacity and costs. Pipeline coating is one of the most reliable corrosion prevention methods used by industries today.

There are several types of coating are used on pipe ,fitting and flange we do a lot.

1.Oil painting

Oil painting is mainly composed of dry oil. It is easy to be good brushing, good wettability on the surface, low price.But the paint film is slow drying, soft film, poor mechanical properties, acid and alkali resistance, water resistance and organic solvent resistance. Oil is often for corrosion resistance requirements are not high in the atmosphere.

2.Black painting

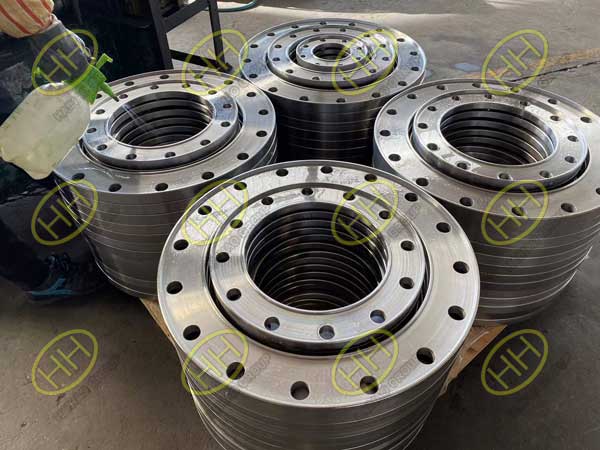

Urushiol is the main component of black painting, strong adhesion, tough film, good luster, it is resistant to soil corrosion, water resistance, oil resistance. but it is not resistant to strong oxidants, poor alkaline resistance. Black painting is our frequently used painting for the carbon steel pipe fittings and flange.

3.Galvanized

Galvanized coating protects the pipeline products from corrosion. It is most commonly used in outdoor buildings such as elbows,tees, flanges, or in some internal plumbing. The galvanized pipeline products are antirust and the galvanizing process is usually less costly than other popular pipe protection methods.

4.Epoxy resin paint

Epoxy coating has good adhesion, excellent adhesion to metal, concrete, wood, glass, etc. Alkali, oil and water resistance, excellent electrical insulation. But poor resistance to aging. Epoxy anticorrosive coatings are usually composed of epoxy resin and curing agent.

5.Polyurethane coating

Polyurethane coating has good physical and mechanical properties. The film is hard, flexible, bright, full, wear-resistant and strong in adhesion. Excellent corrosion resistance. Resistance to oil, acid, chemicals and industrial exhaust. Slightly less alkaline than epoxy paint. Aging resistance is better than epoxy coating. It can be cured at room temperature or by heating, and can be cured at lower temperature (0℃). Polyurethane coatings are expensive but have a long life.

6.Polyethylene and polypropylene coatings

Polyethylene pipeline anti-corrosion sealing, high mechanical strength, waterproof, stable quality, convenient construction, good applicability, no pollution to the environment. PE water absorption rate is low (less than 0.01%), at the same time with high epoxy strength, PE water absorption is low and hot melt adhesive softness is good, has a high corrosion reliability, the disadvantage is: compared with other filling material cost, cost is high. The coating material is rich and has been widely used in corrosion.

7.Heavy anticorrosive paint

Heavy anticorrosion coating is to point to below harsh corrosive condition, anticorrosive effect is taller than general anticorrosive coating several times above anticorrosive coating. It is characterized by excellent performance of strong corrosion resistance medium, outstanding durability and a service life of more than several years. Mainly used in Marine structures and chemical equipment, storage tanks and pipelines, etc.

Commonly used heavy anti-corrosion coatings are:

- Heavy anticorrosive zinc rich coating as primer. It can be divided into three series: thick film organic zinc-rich paint, zinc-rich precoated primer and inorganic zinc-rich paint.

- Heavy anticorrosion intermediate layer coating and finish paint. This kind of coating can be directly coated on the zinc rich primer, mainly chlorinated rubber, ethylene resin, epoxy, polyurethane, chlorinated sulfonated polyethylene, epoxy tar and other heavy anti-corrosion coatings.

- Glass phosphorus sheet heavy anti-corrosion coating.

- Epoxy mortar heavy anti-corrosion coating.

- Fluorine coating. Such as poly – trifluorovinyl chloride coating, fluorine rubber coating.

As a professional pipeline supplier, Haihao Group often advises customers to use suitable pipeline materials and coatings according to the product use environment.So as to reduce corrosion of pipeline products and extend its service life.If you want to know more about our piping products or you want us to advise on your pipeline,please email to us:sales@haihaogroup.com