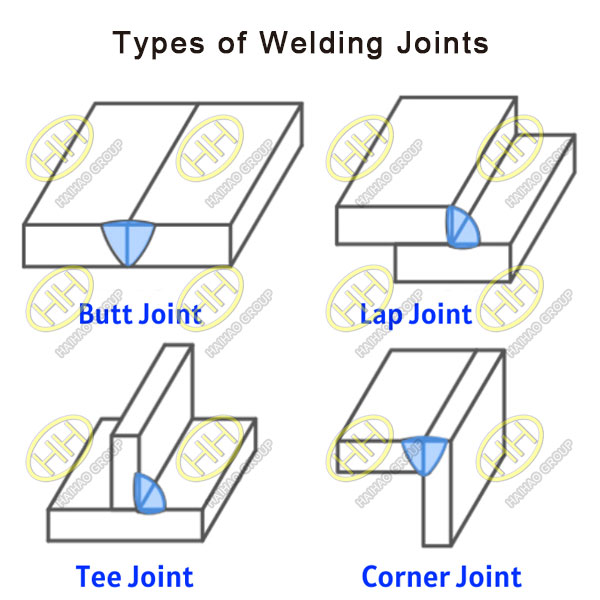

Types and forms of welding joints

In welding, the type of joint varies depending on the thickness, structure, and usage conditions of the workpieces. The most common types of welding joints include butt joints, tee joints, corner joints, and lap joints. Below, we provide a detailed introduction to each of these types.

1.Butt Joint: A joint where the surfaces of two pieces form an angle between 135° and 180° is called a butt joint. It is the most commonly used joint type in various welding structures.

2.Corner Joint: When the end faces of two workpieces form an angle between 30° and 135°, it is called a corner joint. This type of joint, as shown below, does not have a favorable stress condition and is often used in non-critical structures.

3.Tee Joint: A tee joint is formed when the end face of one piece meets the surface of another at a right angle or approximately a right angle, as illustrated below.

4.Lap Joint: A lap joint is created when two pieces partially overlap. Based on its structural form and strength requirements, lap joints are divided into three forms: non-grooved, plug welding in circular holes, and fillet welding in elongated holes, as shown in figures a, b, and c, respectively.

As an expert in the pipeline systems field, Haihao Group frequently assists clients with welding pipeline components, and we have expertise in various welding techniques. If you wish to learn more about our products and services, please feel free to contact us.