What are the mixed grain structures and why they occur in heat treatment?

As an expert in the field of pipeline systems, Haihao Group has extensive experience in heat treatment of many pipe fittings we produce. This article will introduce what mixed grain structures are and why they occur during heat treatment.

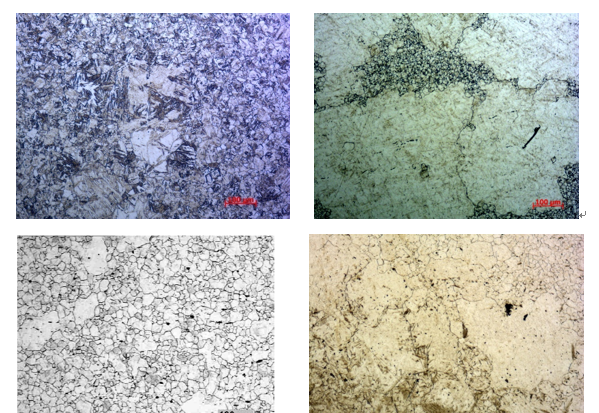

Mixed grain structures, or “mixed grains,” refer to the phenomenon where a metallic material exhibits uneven or irregular grain sizes after undergoing heat treatment. This inconsistency in grain size can negatively impact the material’s mechanical properties and overall performance, making it a critical issue in materials engineering.

Causes of Mixed Grain Structures

Mixed grain structures can arise due to several factors during the heat treatment process, including:

1.Uneven Heating:

Variations in temperature within the material or the furnace can lead to uneven grain growth. Certain regions may experience accelerated grain growth compared to others.

2.Excessive Heating or Prolonged Soaking Time:

Overheating or maintaining the material at high temperatures for an extended period can cause abnormal grain growth, leading to mixed grains.

3.Inhomogeneous Chemical Composition:

If the material has non-uniform distribution of alloying elements, grain growth rates will vary, resulting in mixed grain sizes.

4.Improper Heat Treatment Processes:

Inadequate control of cooling rates during quenching or inconsistent application of the heat treatment process can contribute to the formation of mixed grains.