Why Different Quality Requirements for API 5L Gr. B Seamless steel pipe and SAW Steel Pipes?

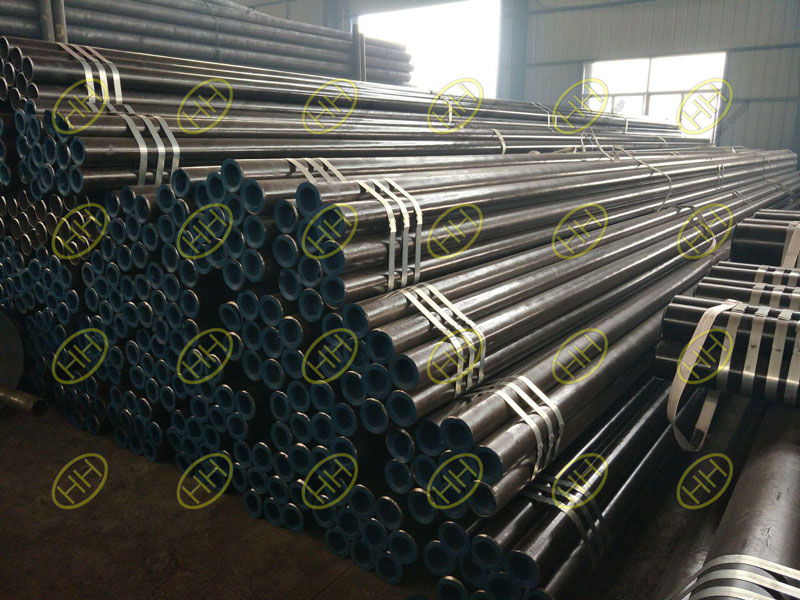

Recently, Haihao Group produced a batch of pipeline system products for a Singapore customer, including two types of steel pipes, API 5L Gr. B seamless steel pipe and SAW steel pipe. Both types of steel pipes follow the ASME B36.10 standard, but when delivered, the customer has different technical requirements for the two types of steel pipes. What is the reason? Let’s take a look at it together.

1.Base Standard: API 5L Gr. B PSL-1

Both seamless and SAW pipes are manufactured in accordance with the API 5L Gr. B PSL-1 standard, which governs line pipes for transporting oil, gas, and water. However, the chemical composition, mechanical properties, and additional testing requirements vary depending on the manufacturing process and intended application.

2.Chemical Composition Requirements

(1)Seamless Pipe (API 5L Gr. B PSL-1)

Carbon (C): ≤ 0.23%

Carbon Equivalent (CE): ≤ 0.43%

Sulfur (S): ≤ 0.010% (for NACE MR0175 compliance)

Other elements follow API 5L guidelines.

(2)SAW Welded Pipe (API 5L Gr. B PSL-1 + 100% RT)

Carbon (C): ≤ 0.23%

Sulfur (S): ≤ 0.020% (≤ 0.003% for NACE)

Phosphorus (P): ≤ 0.025%

Carbon Equivalent (CE): ≤ 0.43%

Nickel (Ni): < 1.0% (for NACE compliance)

Why the difference?

SAW pipes are formed by welding steel plates, which introduces additional heat-affected zones (HAZ) that are more susceptible to hydrogen-induced cracking (HIC). Tighter control on S, P, and Ni minimizes the risk of embrittlement and ensures greater corrosion resistance in sour service conditions.

3.Hardness Requirements

Seamless Pipe: Maximum 22 HRC or equivalent

SAW Pipe (NACE service): Maximum 250 HV10

Why the difference?

The welding process can cause localized hardening in SAW pipes, which makes them more vulnerable to sulfide stress cracking (SSC). Therefore, SAW pipes for sour service must be limited to lower hardness levels to ensure long-term reliability.

4.Heat Treatment & HIC Testing (SAW Only)

For SAW pipes intended for sour service:

HIC Testing (Hydrogen-Induced Cracking) is mandatory

Tempering temperature must be ≥ 620°C if post-weld heat treatment is performed

Rationale:

These additional requirements help reduce residual stress and microstructural hardness in weld zones, improving resistance to internal hydrogen attack in corrosive environments.

5.Non-Destructive Testing (NDT)

Seamless Pipe: Generally not required to undergo 100% RT

SAW Pipe: Must undergo 100% Radiographic Testing (RT)

Why the difference?

Welds are inherently more prone to defects like porosity and incomplete fusion. 100% RT ensures weld integrity and reduces the risk of pipeline failure in the field.

6.Certification: EN 10204 3.1 for Both

Haihao Group provides EN 10204 3.1 mill test certificates for both seamless and SAW steel pipes, ensuring full traceability of chemical and mechanical properties.

The quality requirements for API 5L Gr. B pipes differ significantly between seamless and SAW types due to the welding process and associated risks in corrosive environments. While seamless pipes are naturally homogeneous and often preferred for critical service, SAW pipes, when properly treated and tested, provide a cost-effective and reliable solution for large-diameter, high-pressure applications.

At Haihao Group, we tailor our production and inspection procedures to meet not only API 5L and NACE MR0175 standards but also the unique needs of our global clients. Whether your project demands seamless strength or SAW integrity, we deliver certified quality with full documentation.

Contact us today for a technical consultation or to request a quote for your next pipeline project. Email:sales@haihaogroup.com