What is the difference between SMLS elbow and ERW elbow?

Pipe elbows are essential components in pipeline systems, providing a smooth directional change to ensure fluid flow efficiency. Among the various types, SMLS (Seamless) elbows and ERW (Electric Resistance Welded) elbows are the most common. While both types serve similar functions, they differ significantly in terms of manufacturing processes, appearance, performance, available sizes, and cost. Let’s explore these distinctions in detail.

1.Manufacturing Process Difference

SMLS Elbow:

Seamless elbows are made from a single piece of steel, formed and shaped without any welding. The absence of weld seams ensures higher strength and reliability, making them suitable for high-pressure and high-temperature applications.

ERW Elbow:

ERW elbows are manufactured using steel plates or coils that are rolled and welded along a longitudinal seam. The welding process involves high-frequency electric resistance, which makes these elbows suitable for less demanding applications compared to seamless elbows.

2.Appearance Difference

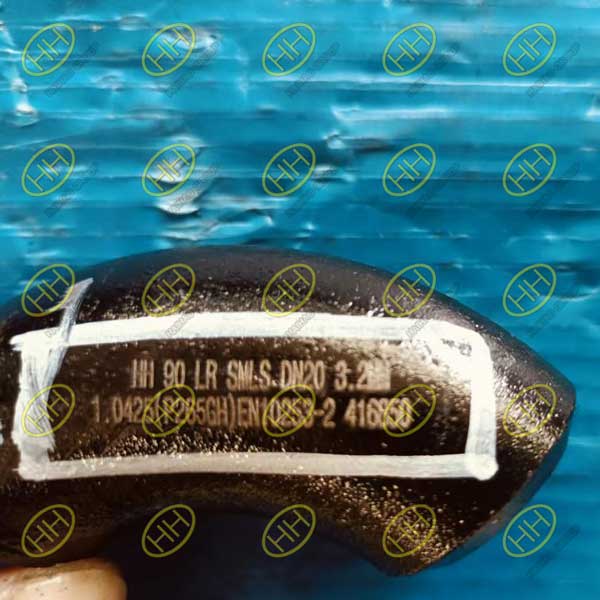

SMLS Elbow:

Seamless elbows have a uniform, smooth appearance without visible weld lines. This makes them aesthetically pleasing and reduces the risk of weak points caused by weld seams.

ERW Elbow:

ERW elbows, on the other hand, typically have a visible weld seam along their surface. While modern manufacturing techniques ensure smooth and high-quality welds, the seam is still distinguishable upon close inspection.

3.Performance Difference

SMLS Elbow:

Seamless elbows are known for their superior mechanical properties and can withstand higher pressures and temperatures. On average, a seamless elbow can handle 20% more working pressure compared to a welded elbow.

ERW Elbow:

ERW elbows, due to the presence of a weld seam, have slightly reduced strength and durability. They are better suited for medium-pressure applications or systems where mechanical stress is relatively low.

4.Size Availability Difference

SMLS Elbow:

The size range for seamless elbows is generally limited by the availability of seamless pipe raw materials. In most cases, the maximum outer diameter for seamless elbows is 24 inches. This size constraint can limit their application in larger pipelines.

ERW Elbow:

Welded elbows do not have the same size limitations as seamless elbows. They can be manufactured in sizes ranging from 1-1/2 inches to 100 inches, making them ideal for large-diameter pipeline systems. The flexibility in size makes ERW elbows a popular choice for customized projects.

5.Cost and Price Difference

SMLS Elbow:

Due to the complexity of the seamless manufacturing process and the higher quality of the finished product, seamless elbows are generally more expensive. The cost includes the premium for the raw materials and the advanced techniques used in production.

ERW Elbow:

ERW elbows are more cost-effective as they are easier and faster to manufacture. The welding process allows for efficient production, reducing the overall cost. For applications where high pressure is not a concern, ERW elbows provide a budget-friendly alternative.

The choice between SMLS elbows and ERW elbows largely depends on the specific requirements of the pipeline system. For high-pressure and high-temperature applications, seamless elbows are the preferred option due to their strength and durability. However, for larger diameters or projects with budget constraints, ERW elbows offer a practical and economical solution.

As an expert in the field of piping systems, Haihao Group can produce both seamless elbows and welded elbows. If you need these products, please feel free to contact us. Email:sales@haihaogroup.com