Exploring the benefits of inner and outer coatings on steel pipes

Steel pipes are widely used in various industries, including oil and gas, construction, and manufacturing. To ensure their durability and longevity, proper coating is essential. Coating not only protects the steel pipes from corrosion and rust but also improves their appearance. In this article, we will introduce the different types of coatings used for steel pipes, including inner and outer coatings.

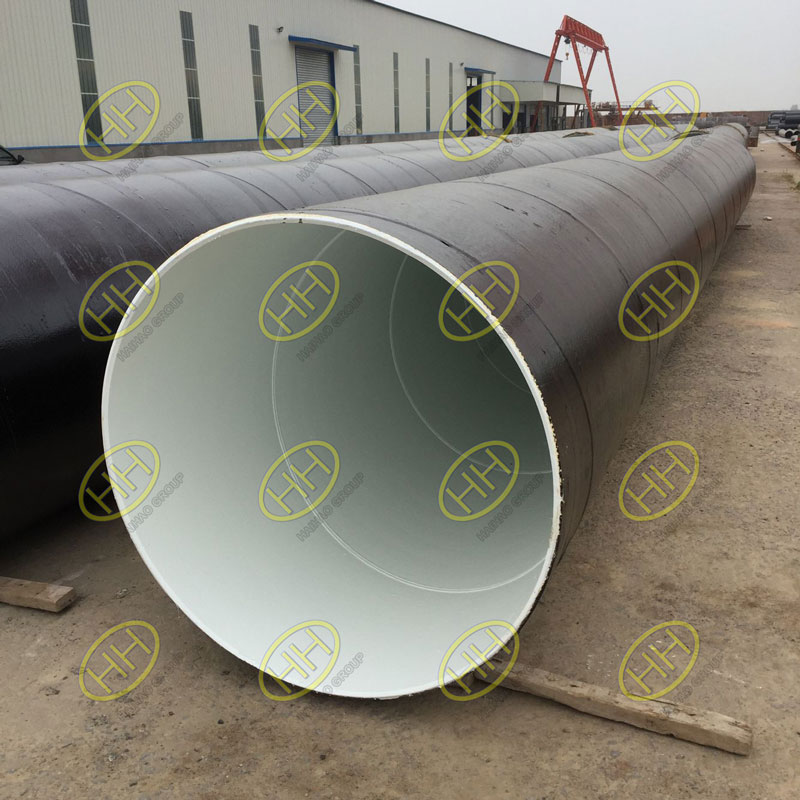

Inner coatings are applied to the inside of steel pipes and protect them from corrosion caused by the fluid flowing through them. There are several types of inner coatings, including epoxy coating, cement mortar lining, and polyethylene lining. Epoxy coating is a popular choice for pipes used in water and wastewater treatment plants because of its resistance to chemicals and abrasion. Cement mortar lining is commonly used in pipes that transport drinking water because it provides a protective barrier against contamination. Polyethylene lining is ideal for pipes that transport gas and oil because it provides excellent resistance to chemicals and abrasion.

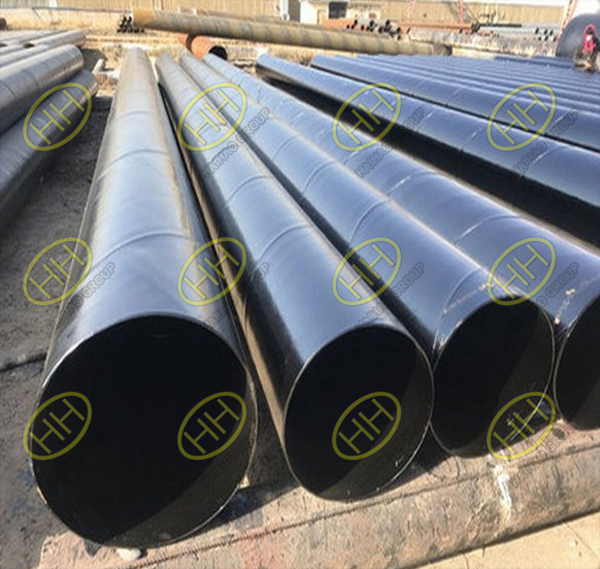

Outer coatings are applied to the exterior of steel pipes and protect them from corrosion caused by the surrounding environment. There are also several types of outer coatings, including polyethylene coating, polyurethane coating, and fusion-bonded epoxy coating. Polyethylene coating is a common choice for pipes used in the gas and oil industry because it provides excellent resistance to weather, chemicals, and abrasion. Polyurethane coating is ideal for pipes used in harsh environments because it provides superior protection against weathering, abrasion, and impact. Fusion-bonded epoxy coating is commonly used in pipes that transport drinking water because of its excellent resistance to corrosion and chemicals.

At our company, we understand the importance of coating steel pipes to protect them from corrosion and improve their durability. We provide a range of coating options for both inner and outer coatings, including epoxy, polyethylene, polyurethane, and fusion-bonded epoxy. Our coatings are applied using state-of-the-art equipment and techniques, ensuring the highest level of quality and performance. We also offer customization options to meet the unique needs of our clients.

In conclusion, proper coating is essential for steel pipes to ensure their longevity and durability. Inner coatings protect pipes from corrosion caused by the fluid flowing through them, while outer coatings protect pipes from corrosion caused by the surrounding environment. At our company, we provide a range of coating options to meet the unique needs of our clients. Contact us today to learn more about our steel pipes and various pipe coatings.