How to do dye penetrant inspection or liquid penetrant inspection?

What is dye penetrant inspection?

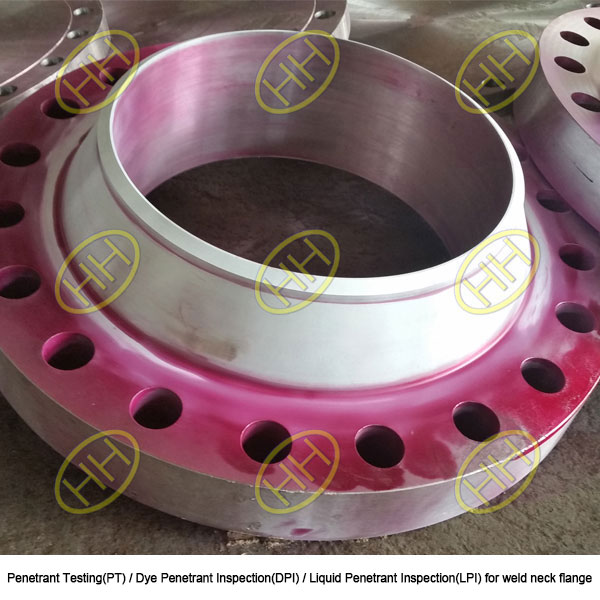

Dye penetrant inspection(DPI) is one of the non-destructive testing,also known as liquid penetrant inspection (LPI) or penetrant testing,is a cost-effective method used to locate surface breaking flaws such as cracks,porosity,laps,seams and other surface discontinuities.Dye penetrant inspection can be applied to inspect the welds,plate,bars,pipes,castings,and forgings.

How to do dye penetrant inspection or liquid penetrant inspection?

There are six basic steps to follow when using the dye penetrant solvent removable method.

1.Surface Preparation

The surface must be free of oil,grease,water,or other contaminants that may prevent penetrant from entering flaws.The sample may also require etching if mechanical operations such as machining,sanding,or grit blasting have been performed.These and other mechanical operations can smear metal over the flaw opening and prevent the penetrant from entering.

2.Apply penetrant

The penetrant material is applied by spraying,brushing,or immersing the part in a penetrant bath.A dwell (soak) time needs to be observed to allow for the penetrant to permeate into cracks and voids.Minimum dwell times typically range from five to 60 minutes.Generally,there is no harm in using a longer penetrant dwell time as long as the penetrant is not allowed to dry.

3.Remove penetrant

In this step, the inspector carefully removes excess penetrant without removing penetrant from the defects.Water or emulsifiers are sometimes used.The removal method is controlled by the type of penetrant used.Water-washable,solvent-removable,lipophilic post-emulsifiable,or hydrophilic post-emulsifiable are the common choices.

4.Application of developer

A thin,light coating of developer should be sprayed on the part being examined.Developers come in a variety of forms that may be applied by dusting (dry powdered),dipping,or spraying (wet developers).The developer is allowed to stand on the part surface for a period of time sufficient to permit the extraction of the trapped penetrant out of any surface flaws. This development time is usually a minimum of 10 minutes. Significantly longer times may be necessary for tight cracks.

5.Inspection

Inspection is then performed under appropriate lighting to detect indications from any flaws which may be present.

6.Clean surface

The last step is to remove the developer material from the areas of the surface lacking in defects.

The advantages of dye penetrant inspection

It is generally accepted that dye penetrant inspection has the following advantages:

- Sensitive to small surface discontinuities

- Few material limitations-works on metallic,non-metallic,magnetic,non-magnetic,conductive,and non-conductive materials

- Works on complex geometric shapes

- Visual,real-world results

- Dye penetrant inspection materials are very portable

- Dye penetrant inspection materials are individually very affordable

penetrant testing or dye penetrant inspection or liquid penetrant inspection for large caliber elbow weld

The disadvantages of dye penetrant inspection

- Only surface breaking defects can be detected.

- Only materials with a relatively nonporous surface can be inspected.

- Precleaning is critical since contaminants can mask defects.

- Metal smearing from machining, grinding, and grit or vapor blasting must be removed prior to LPI.

- The inspector must have direct access to the surface being inspected.

- Surface finish and roughness can affect inspection sensitivity.

- Multiple process operations must be performed and controlled.

- Post cleaning of acceptable parts or materials is required.

- Chemical handling and proper disposal is required.

Haihao Group has been a professional supplier of pipes,fittings and flanges,serving the world industry piping since 1982.As a leading manufacturer,stockist and supplier,our products used well in oil and gas development,power plant,chemical industrial,shipbuilding and offshore,steel constructions and so on,we can provide dye penetrant inspection on-site at our customer’s premises or at our accredited laboratories.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com