Properties and advantages of ASTM A105 carbon steel flanges

ASTM A105 is a forged carbon steel material widely used for manufacturing flanges, fittings, and piping components in high-pressure and high-temperature environments. It is commonly used in oil & gas, petrochemicals, power plants, and refineries due to its excellent mechanical properties, durability, and cost-effectiveness.

This material is suitable for seamless and welded piping systems and operates within a temperature range of -29°C to 425°C (-20°F to 800°F), making it an ideal choice for various industrial applications.

Key Properties of ASTM A105 Carbon Steel

ASTM A105 is a fine-grain, fully killed carbon steel that offers:

High tensile and yield strength, ensuring structural integrity in high-pressure systems.

Good impact resistance, reducing the risk of brittle failure.

Excellent machinability, making it easy to manufacture complex flange designs.

Reliable weldability, allowing for strong and secure pipe connections.

Typical mechanical properties include:

- Tensile Strength: Minimum 485 MPa (70 ksi)

- Yield Strength: Minimum 250 MPa (36 ksi)

- Elongation: Minimum 22%

- Hardness: Maximum 187 HBW

These properties ensure that ASTM A105 flanges maintain their strength under extreme operating conditions.

Why ASTM A105 Flanges Are Ideal for High-Temperature & High-Pressure Systems

Flanges used in high-pressure pipelines and high-temperature applications must withstand extreme conditions without deformation or failure. ASTM A105 carbon steel flanges offer:

High mechanical strength, ensuring stability in pressurized systems. Good thermal stability, making them suitable for steam, gas, and high-temperature fluid transport.

Superior fatigue resistance, preventing failures under fluctuating loads.

Cost-effectiveness, providing a more economical solution compared to stainless steel or alloy materials.

Because of these advantages, ASTM A105 flanges are commonly used in:

- Oil & Gas Pipelines

- Petrochemical Refineries

- Power Plants (Steam & Gas Turbines)

- High-Pressure Water and Steam Systems

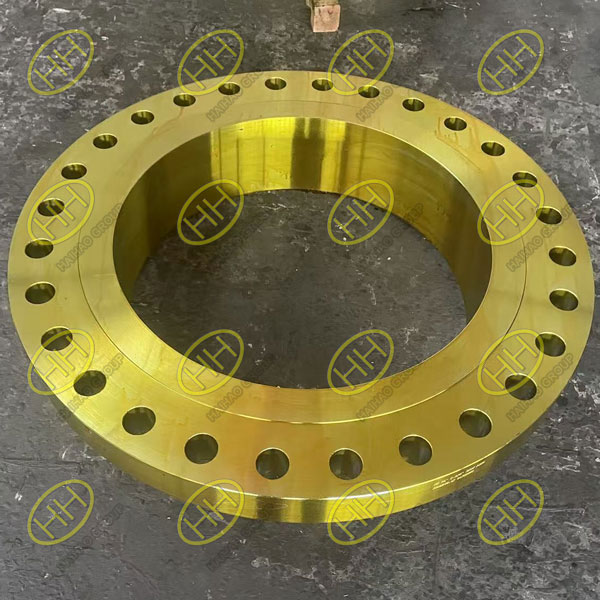

Haihao Group’s Quality Assurance for ASTM A105 Flanges

Haihao Group ensures high-quality ASTM A105 flanges through a rigorous quality control process, including:

Chemical Composition Testing – Using spectrochemical analysis to verify material composition.

Mechanical Property Testing – Conducting tensile, hardness, and impact tests to confirm strength and durability.

Non-Destructive Testing (NDT) – Performing ultrasonic and radiographic inspections to detect internal defects.

Dimensional Inspection – Ensuring flanges meet ASME B16.47 and ASME B16.5 standard.

Pressure & Leak Testing – Simulating real-world pressure conditions to guarantee flange performance.

With advanced manufacturing capabilities and strict quality control, Haihao Group supplies reliable ASTM A105 carbon steel flanges for global industrial projects.

Looking for ASTM A105 flanges? Contact Haihao Group today for expert solutions! Email:sales@haihaogroup.com