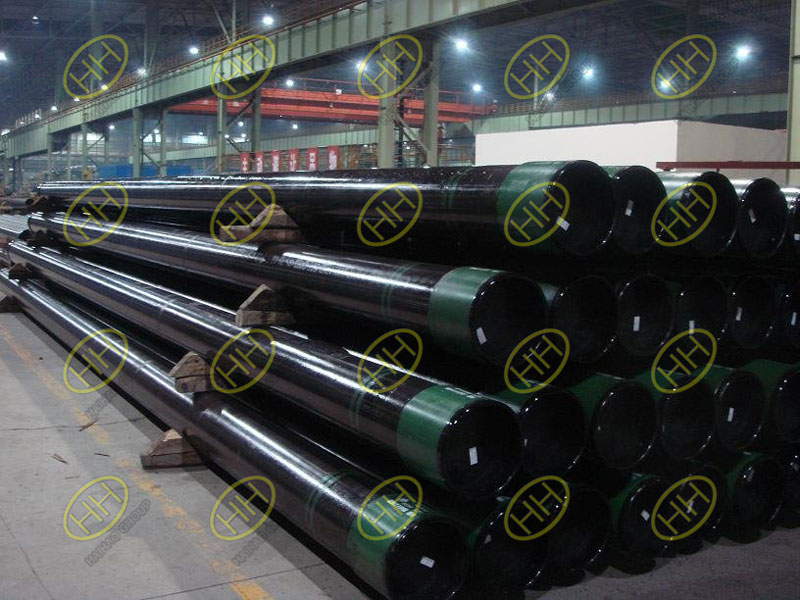

Steel casing pipes

Steel casing pipe,also known as encasement pipe,is most commonly used in underground construction to protect utility lines of various types from getting damaged.Steel casing pipe is used in different types of horizontal underground boring,where the pipe is jacked into an augered hole in segments and then connected together by welding or by threaded and coupled ends,or other proprietary pipe connectors such as the interference-fit Permalok interlocking push-on joint.Steel casing pipe protects one or many of various types of utilities such as water mains,gas pipes,electrical power cables,fiber optic cables,etc.

Specification of steel casing pipes:

| Manufacture Type: | Seamless steel pipe,welding steel pipe |

| Parts: | Casing,tubing ,coupling ,thread protector |

| Size Range(OD): | Seamless:114.3-406.4mm |

| Welding:88.9-660.4mm | |

| Length range | 6-13m |

| Standard: | API 5CT |

| Certification: | API 5CT, GOST, ISO9001, ISO14001,OHSMS18000 |

| Grades | API 5CT J55/K55/N80/L80-1/L80-9Cr/L80-13Cr/P110/Q125/K55 D10/L80 D10. |

| Type of thread: | STC,LTC,BTC,XC,NU,EU, XBY premium |

| Surface Treatment: | Fusion bond epoxy coating,coal tar epoxy,3PE,varnish coating,bitumen coating,black oil coating as per customer’s requirement. |

| Testing: | Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test,X-ray Test. |

| Testing Report: | SGS,BV etc.3rd Party Testing Report is available . |

| Customized Size: | Non-standard size can be customized as per customer’s request. |

Dimension tolerance of steel casing pipes:

| Types of steel tubes | Outer Diameter | Wall Thickness | |

|

Cold-rolled tubes |

Tube sizes(mm) | Tolerances(mm) |

Tolerances(mm) |

|

<114.3 |

±0.79 |

-12.5% |

|

|

≥114.3 |

-0.5%,+1% |

||

Chemical Composition of API 5CT steel casing and tubing pipes:

| Chemical composition,mass fraction(%) | |||||||||||||||

| Group | Grade | Type | C | Mn | Mo | Cr | Ni | Cu | P | S | Si | ||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Max. | Max. | Max. | Max. | Max. | |||

| 1 | H40 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – |

| J55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | |

| K55 | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | ||||

| N80 | 1 | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | |

| N80 | Q | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | |

| R95 | – | – | 0.45 | – | 1.90 | – | – | – | – | – | – | 0.03 | 0.030 | 0.45 | |

| 2 | M65 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – |

| L80 | 1 | – | 0.43 | – | 1.90 | – | – | – | – | 0.25 | 0.35 | 0.03 | 0.030 | 0.45 | |

| L80 | 9Cr | – | 0.15 | 0.30 | 0.60 | 0.90 | 1.10 | 8.00 | 10.00 | 0.50 | 0.25 | 0.02 | 0.010 | 1.00 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1.00 | – | – | 12.00 | 14.00 | 0.50 | 0.25 | 0.02 | 0.010 | 1.00 | |

| C90 | 1 | – | 0.35 | – | 1.20 | 0.25 | 0.85 | – | 1.50 | 0.99 | – | 0.02 | 0.010 | – | |

| T95 | 1 | – | 0.35 | – | 1.20 | 0.25 | 0.85 | 0.40 | 1.50 | 0.99 | – | 0.02 | 0.010 | – | |

| C110 | – | – | 0.35 | – | 1.20 | 0.25 | 1.00 | 0.40 | 1.50 | 0.99 | – | 0.02 | 0.005 | – | |

| 3 | P110 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – |

| 4 | Q125 | 1 | – | 0.35 | – | 1.35 | – | 0.85 | – | 1.50 | 0.99 | – | 0.02 | 0.010 | – |

- a.The carbon content for L80 may be increased up to 0.50% maximum if the product is oil-quenched.

- b. The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the WT is less than 17,78mm.

- c.The carbon content for R95 may be increased up to0.55% maximum if the product is oil-quenched.

- d.The molybdenum content for T95 Type 1 may be decreased to 0.15% minimum if the WT is less than 17,78mm.

- e. For EW Grade P110,the phosphorus content shall be 0.020% maximum and the sulfur content 0.010% maximum

- NL=no limit.Elements shown shall be reported in product analysis.

Mechanical Properties of API 5CT steel casing and tubing pipes:

| Mechanical Properties | ||||||||

| Group | Steel Grade | Type | Total | Yield Strength (Mpa) | Tensile Strength (Mpa) | Hardness max. | ||

| % | min. | max. | MPa | HRC | HWB | |||

| 1 | H40 | – | 0.5 | 276 | 552 | 414 | – | – |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – | |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – | |

| R95 | – | 0.5 | 655 | 758 | 724 | – | – | |

| 2 | M65 | – | 0.5 | 448 | 586 | 586 | 22 | 235 |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | |

| C110 | – | 0.7 | 758 | 828 | 793 | 30 | 286 | |

| 3 | P110 | – | 0.6 | 758 | 965 | 862 | – | – |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | – | |

- a.In case of dispute,laboratory Rockwell C hardness testing shall be used as the referee method.

- b.No hardness limits are specified,but the maximum variation is restricted as a manufacturing control in accordance with API 5CT.

We have a large inventory of ASTM 5CT steel casing and tubing pipes.Normal inventory includes pipe diameter sizes: 2″,3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 22″, 24″, 30″, and 36″. Also available in larger diameters to 110″ with wall thicknesses ranging in thickness from 0.25″-1″depending upon the pipe OD.