What’s the difference between hot rolling and cold rolling

Hot rolling and cold rolling are the forming processes of section steel or steel plate, which have great influence on the structure and properties of steel.Cold rolling is done below the recrystallization temperature,while hot rolling is done above the recrystallization temperature.There are the difference between hot rolling and cold rolling:

- Local buckling is allowed in the section of cold-rolled section steel, so that the bearing capacity of the bar after buckling can be fully utilized; But the section of hot rolled section is not allowed to have local buckling.

- The residual stress of hot rolled section and cold rolled section is caused by different reasons, so the distribution on the section is also very different. The distribution of residual stress on the section of cold-formed thin-walled section is curved, while that on the section of hot-rolled or welded section is thin-film.

- The free torsional stiffness of hot rolled section is higher than that of cold rolled section, so the torsional resistance of hot rolled section is better than that of cold rolled section.

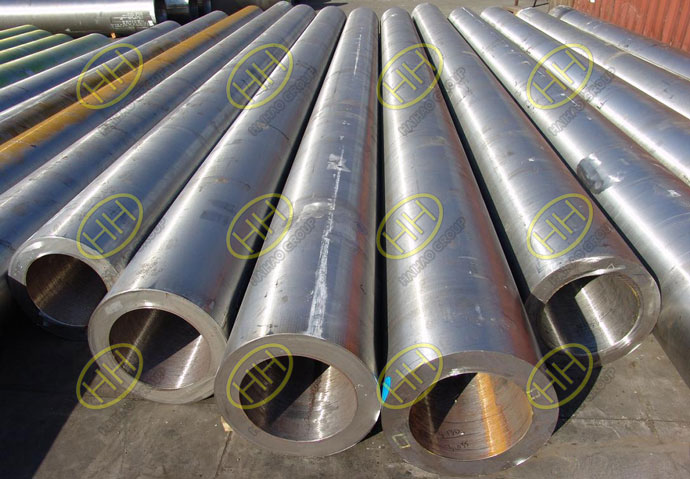

Haihao Group manufacture cold rolling and hot rolling steel pipes,which contain seamless steel pipes,welded steel pipes(ERW/LSAW steel pipes),galvanized steel pipes,3LPE and 2LPE coated pipes etc.The materials are carbon steel,stainless steel,alloy steel.

If you require large structural components,you will most likely need the hot rolling steel process to create the parts.For smaller parts that require more precise and durable qualities,then the cold rolling steel process is the way to go.If you have questions about which mill process you need for your project,feel free to email us:sales@haihaogroup.com