Difference between hot galvanized and cold galvanized

What is hot galvanized and cold galvanized?

Hot-dip galvanized is a method in which steel components are immersed in molten zinc to obtain a metal coating.The workpiece is degreased,pickled,dipped,dried and immersed in molten zinc.

Cold galvanized(galvanizing) also called electro-galvanized cold galvanizing, which is the use of the pipe member through electrolysis degreasing,pickling,and put into a solution composed of zinc and a cathode connected to the electrolytic apparatus,placed opposite the tube member zinc plate,connected to the electrolysis the positive power equipment,the use of electric current from the positive to the negative directional movement will be in a layer of zinc deposited on pipe fittings, cold-plated fittings are galvanized after processing the first.

The difference between hot galvanized and cold galvanized:

1. As a metal anticorrosive method,hot-dip galvanized means puttingthe steel structure which will be rust-removed into the zinc solution at about 500℃,to make the zinc layer adhere to the surface of the steel structure.

Cold galvanized makes the surface of metal and other materials adhere to a metal film through electrolysis,which makes the surface of the material uniform in texture, anti-corrosive and wear-resistant,more beautiful in appearance.

2. Hot-dip galvanized coatings are thicker,generally 30-60 micrometers,and have higher corrosion resistance.It is suitable for the long-term rust-proof for outdoor work of steel parts,such as highway fences,power towers,large-scale fasteners and other relatively “rough” parts.Cold galvanizing work piece surface is smooth,but its coating is relatively thin with generally 5-30 micrometers,so the corrosion protection time will be shorter.It is used for rust prevention of indoor parts,such as chassis bottom,panel,small size fasteners,etc.

3. Hot-dip galvanizing protects steel and other materials electro chemically based on the anti-atmospheric corrosion principle of zinc.The zinc carbonate protective film on the surface can slow down the corrosion rate of zinc.Even if it is destroyed,the zinc film will be formed again.Cold galvanizing is a chemical way to separate zinc alloys into zinc ionsattached to the surface of steel.The new layer formed by this way is generally thin,and steel is prone to rust in general.

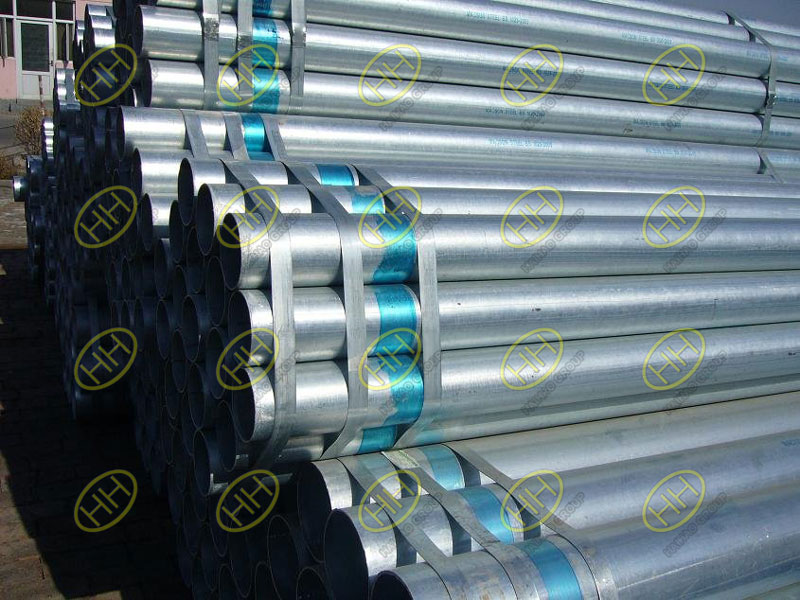

4. The outer surface of cold galvanized steel pipe is smooth and bright.The electroplating layer of iridescent passivation technology will show yellow-green,and the electroplating layer of white passivation process will be blue-white.Generally,there are only a few zinc layers at both ends of cold galvanized steel pipe,and there is no zinc layer inside it.The outer surface of hot-dip galvanizing is rough,dark and generally silver-white.Because of the production process,there are some water marks and droplets on the surface.The surface does not emit light or reflect light.Hot-dip galvanized steel pipe has complete galvanized coating both inside and outside.

Haihao Group can supply hot galvanized and cold galvanized steel pipes,pipe fittings and flanges products,the products materials contain carbon steel,stainless steel,alloy steel.If you want to know more about our piping products,please feel free to contact us:sales@haihaogroup.com