Welding of low carbon steel and medium carbon steel

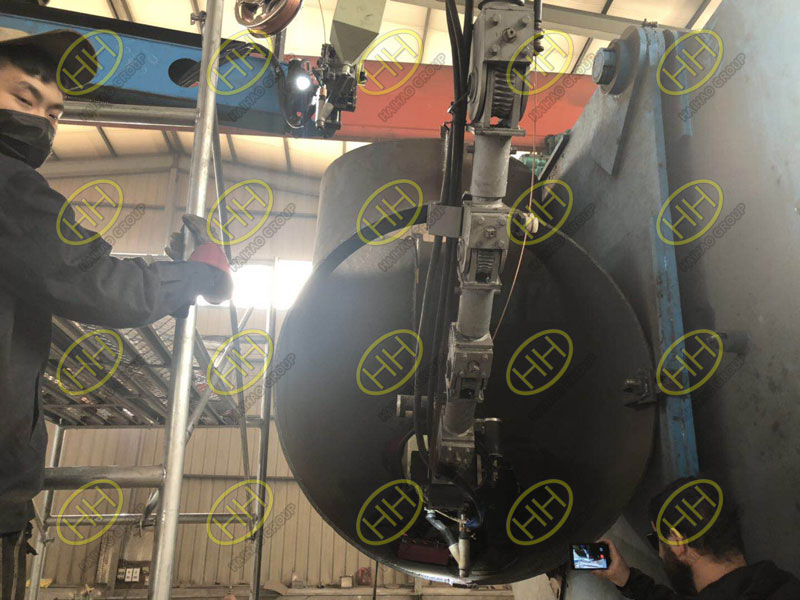

As a professional supplier of pipeline system components, Haihao Group produces a wide range of fittings in various materials, often requiring extensive welding operations. With our rich welding experience, we understand the nuances of welding different types of steel.

How to Weld Low Carbon Steel?

Low carbon steel, with its low carbon content, offers excellent plasticity and can be formed into various joints and components. During the welding process, it is less likely to develop hardening structures or cracks, and it typically resists porosity, making it one of the easiest materials to weld. Techniques such as gas welding, manual arc welding, submerged arc welding, and gas shielded welding can all produce quality joints.

When using gas welding, it is crucial to avoid prolonged heating, as this can enlarge the grain structure in the heat-affected zone. In cases where the joint has high rigidity or the surrounding temperature is low, preheating the workpiece to 100-150°C is recommended to prevent cracking.

How to Weld Medium Carbon Steel?

Medium carbon steel contains a higher carbon content, which can lead to hardening structures and cracks in the weld and heat-affected zone. Therefore, preheating to around 300°C is essential before welding, followed by a slow cooling process after welding. Suitable methods for welding medium carbon steel include gas welding, manual arc welding, and gas shielded welding. It’s important to choose welding materials with good crack resistance, such as electrodes 506 and 507.

At Haihao Group, we leverage our extensive welding expertise to ensure high-quality connections in our pipeline components, meeting the diverse needs of our customers in the industry.