API 5L PSL2 3LPE seamless pipes supplied to the North Rumaila oilfield

Rumaila Oilfield is located 50 kilometers west of Basra in southern Iraq. It is a giant oilfield, ranking sixth in the world. The amount of external procurement is very large every year. Our company supplies oil, gas, shipbulding, water treatment and other engineering projects all year round. We were lucky to be the supplier of Rumaila Oilfield many years ago, and now we have established a good cooperative relationship.

Recently, we have also supplied about 430 tons of steel pipes, pipe fittings, flanges, and bolts and gaskets for flange connection accessories. 3LPE coating is required for the steel pipe and several elbows. We are very familiar with 3LPE coating, and provide it all the year round. All technical specifications can be interpreted very well.

In addition to controlling chemical composition and mechanical properties, we also conducted NDT during production and processing. Because the goods are carbon steel products, we conducted MT testing on pipe fittings, UT and MT on flanges, 100% X-ray testing on welded pipes, and provided RT report. After the coating is completed, 3LPE also was strictly tested, and provided the NPT report to the customer.

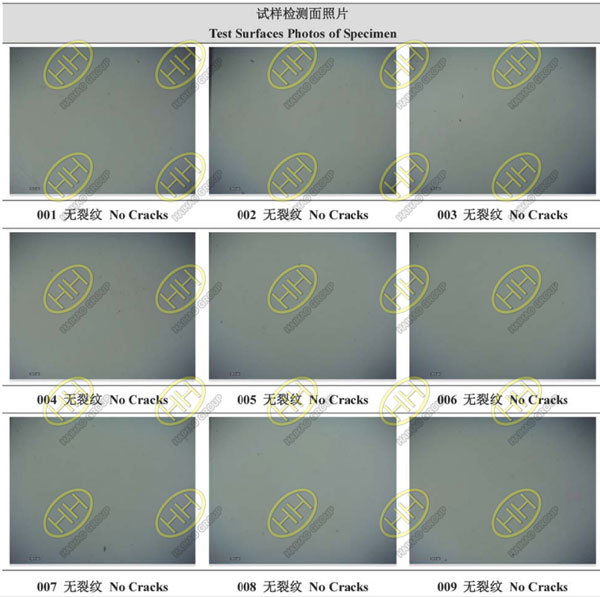

This material of 3LPE seamless pipe is API 5L GRADE X60, PSL 2. The customer’s technical requirements are higher than API 5L GRADE X52, and HIC test is required. After the production of pipes, we directly cut a block from one pipe for HIC test, and the test results are completely qualified.