-

Not long ago, a customer from the UK ordered a batch of ASTM A234 WPB carbon steel elbows from our company. This batch of products was used in a chemical project in the UK. According to the needs of the customer, we recommended the appropriate coating type ...

-

At Haihao Group, we take great pride in producing high-quality pipe fittings, including the ASTM A234 WPB 40-inch carbon steel elbows. With a relentless focus on precision and craftsmanship, we ensure that our elbows meet and exceed industry standards. In ...

-

When it comes to pipeline systems, it’s essential to understand that not all pipelines are created equal. The specific requirements and challenges posed by different types of fluids necessitate distinct approaches in material selection, coating, desi ...

-

When it comes to flange steel pipe joints, ensuring a secure and leak-free connection is of utmost importance. One critical aspect of achieving this is the proper treatment of welding seams. At Haihao Group, we take pride in our expertise in providing top- ...

-

We are thrilled to announce that Haihao Group has successfully completed the galvanization process for the flanged steel pipe joints ordered by our valued customers. Galvanizing these products is a critical step that significantly enhances their durability ...

-

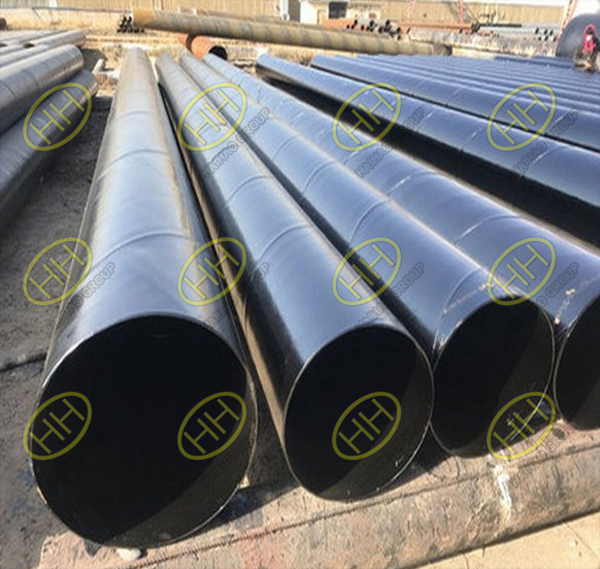

Steel pipes are widely used in various industries, including oil and gas, construction, and manufacturing. To ensure their durability and longevity, proper coating is essential. Coating not only protects the steel pipes from corrosion and rust but also imp ...

-

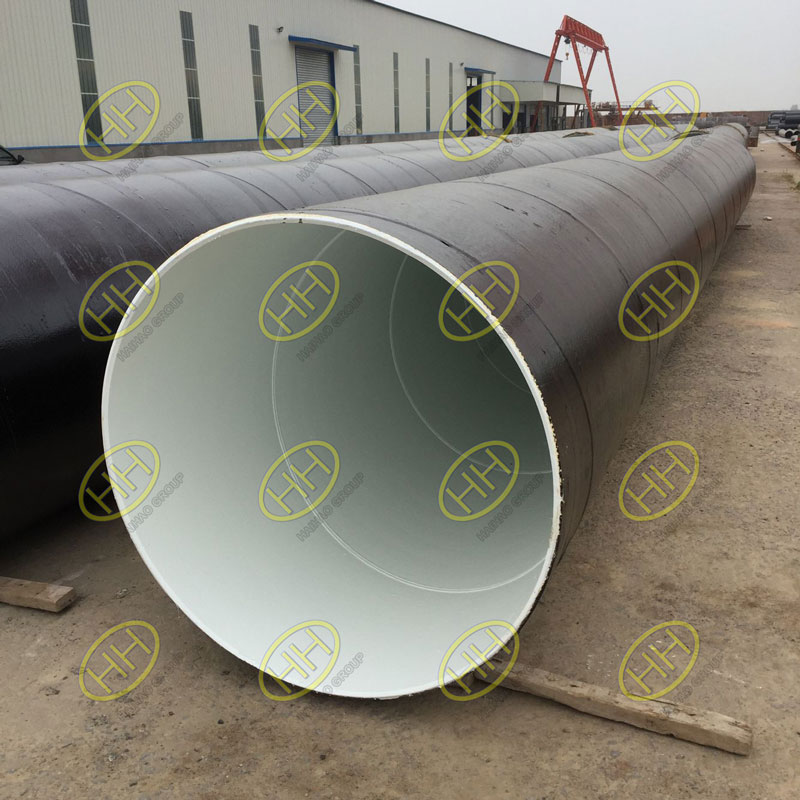

At Haihao Group, we are committed to providing our customers with high-quality products that meet their unique requirements. Recently, we received an inquiry from a customer who required a welded pipe with a plastic-coated flange for use in potable water a ...

-

When it comes to pipe fittings, elbows are an important component that helps to change the direction of the flow of fluids in pipelines. However, not all elbows are created equal – there are two types of elbows commonly used in piping systems: short ...

-

Pipe fittings are essential components of piping systems, and they come in various materials to suit different applications. One material that is becoming increasingly popular in the industry is ASTM A182 F321.ASTM A182 F321 is a titanium-stabilized austen ...

-

High-pressure, high-temperature, and corrosion-resistant environments pose significant challenges for pipe fittings, and it takes a high level of expertise to manufacture fittings that can withstand these conditions. Our company has extensive experience in ...

-

Haihao Group is a leading supplier of pipeline products, and we take pride in providing our customers with a wide range of products to meet their diverse needs. In addition to Various standard elbows, flanges, tees, and steel pipes, we also offer threaded ...

-

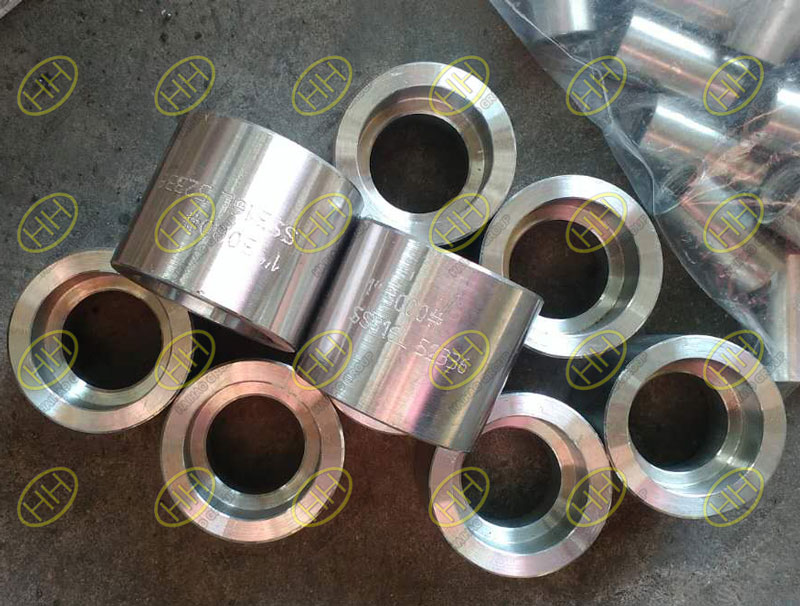

At our company, quality is a top priority. We are committed to providing our customers with high-quality ASME B16.11 and EN10241 1/2″ to 24″ DN15-DN 600 forged pipe fittings that meet their specific requirements. To ensure that our products mee ...

-

At our company, we take pride in providing high-quality ASME B16.11 and MSS-SP 75 and BS 3799 forged steel pipe fittings. Forged pipe fittings are available in various types, such as elbows, tees, reducers, union,cap, couplings and so on. Manufacturers can ...

-

ASTM A182 F304 forged steel pipe fittings are widely used in various industries due to their high strength, excellent corrosion resistance, and durability. These pipe fittings are suitable for use in extreme environments, including nuclear power plants, su ...

-

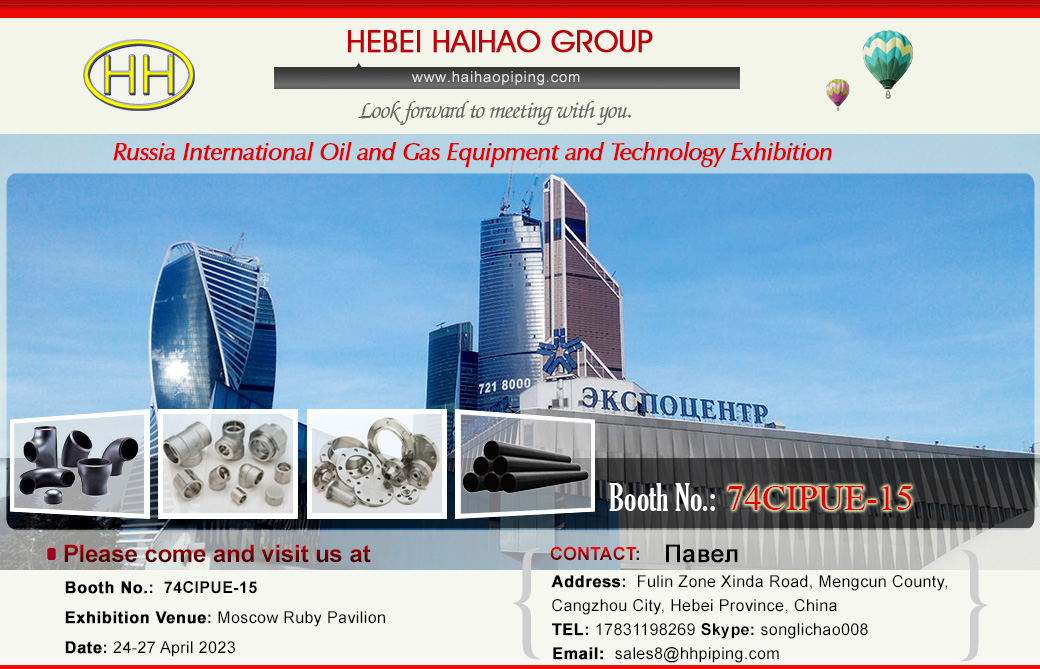

NEFTEGAZ is an international exhibition for the oil and gas industry, which is held annually in Moscow, Russia. The exhibition has been held for over 40 years, and it has become one of the largest events in the industry, attracting participants and visitor ...

-

ASME B16.11 ASTM A182 F304 forged steel pipe fittings and ASME B16.11 ASTM A182 F316 forged steel pipe fittings are essential components in extreme environments where standard pipe fittings cannot withstand the harsh conditions. These fittings are made fr ...

-

ASME B16.11 is a standard specification that provides the detailed dimensions, material requirements, and testing procedures for forged steel fittings, socket-welding, and threaded. It covers fittings in sizes from 1⁄8 inch to 4 inches in diameter, with pr ...

-

ASME B16.11 ASTM A182 F316 pipe fittings are high quality fittings that are designed for use in demanding applications where high pressure and temperature conditions are present. These fittings are manufactured according to ASME B16.11 standards and are ma ...

-

In the field of piping, ASME B16.11 is the standard that governs the requirements for forged fittings, including elbow, tee, cross, coupling, and union, among others. Meanwhile, ASTM A182 F304 is the specification for forged or rolled alloy and ...

-

B36.10M A53 Gr.B steel pipes are widely used in many industries. However, to ensure the durability and longevity of these pipes, they need to be protected with a coating. One such coating is the 3PE coating, which is widely used on B36.10M A53 Gr.B steel p ...