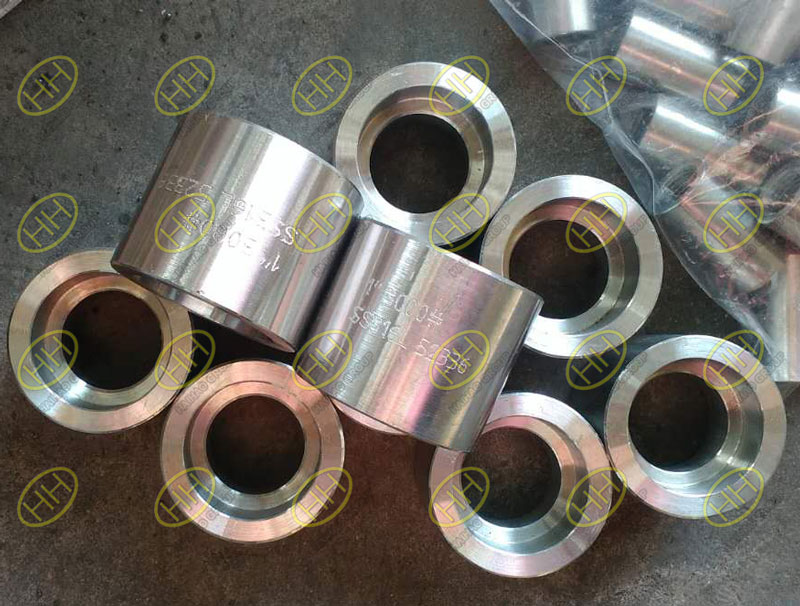

Diverse stainless steel fittings meeting varied standards available at Haihao Group

Haihao Group is pleased to introduce our wide range of stainless steel fittings, tailored to meet different standards, providing exceptional corrosion resistance and mechanical performance. Our products are meticulously crafted to ensure durability and reliability in various industrial applications.

Corrosion Resistance: 316L stainless steel is widely acclaimed for its outstanding corrosion resistance in the chemical industry. Derived from the 18-8 austenitic stainless steel, 316L incorporates 2-3% Mo for enhanced corrosion resistance. Variants such as 316Ti with added Ti and 316N with added N have emerged from the base 316L. Additionally, 317L, with increased Ni and Mo content, offers further corrosion resistance.

Existing 316L products in the market are mostly produced according to American standards. The ASTM standard specifies a Ni content of 10-14% for 316L, while the Japanese standard (JIS) specifies 12-15% Ni content. The difference in Ni content between ASTM and JIS standards can be up to 2%. Hence, customers should clarify whether the product conforms to ASTM or JIS standards when purchasing 316L products.

The Mo content in 316L imparts excellent pitting corrosion resistance, making it suitable for environments containing halide ions such as Cl-. Given its primary application in chemical environments, steel mills have slightly lower surface inspection requirements for 316L compared to 304. Customers with higher surface requirements should enhance surface inspection.

Material Differences Between 316 and 316L:

Domestic grades: 316 is labeled as 0Cr17Ni12Mo2 (low carbon stainless steel), while 316L is labeled as 00Cr17Ni14Mo2 (ultra-low carbon stainless steel).

Corrosion Resistance: 316L exhibits superior corrosion resistance compared to 316, albeit with slightly inferior mechanical properties.

316 and 316L stainless steels are molybdenum-bearing stainless steel grades. The Mo content in 316L is slightly higher than in 316. With molybdenum, these grades outperform 310 and 304 stainless steels. 316 stainless steel finds extensive use in various industries, especially in marine environments due to its excellent resistance to chloride corrosion.

316 stainless steel demonstrates good oxidation resistance below 1600°C intermittently and below 1700°C continuously. It is not advisable to use 316 stainless steel continuously between 800-1575°C. However, beyond this temperature range, 316 stainless steel exhibits good heat resistance. The carbide precipitation resistance of 316L stainless steel is superior to that of 316, making it suitable for use within the specified temperature range.

Haihao Group offers a comprehensive selection of stainless steel fittings, including tees, elbows, reducers, and more, meeting ASTM and JIS standards. Our commitment to quality ensures that our products deliver exceptional performance, reliability, and longevity in diverse industrial environments. Contact us today to explore our range of stainless steel fittings tailored to your specific needs.