What is the 3PE anti-corrosion coating?

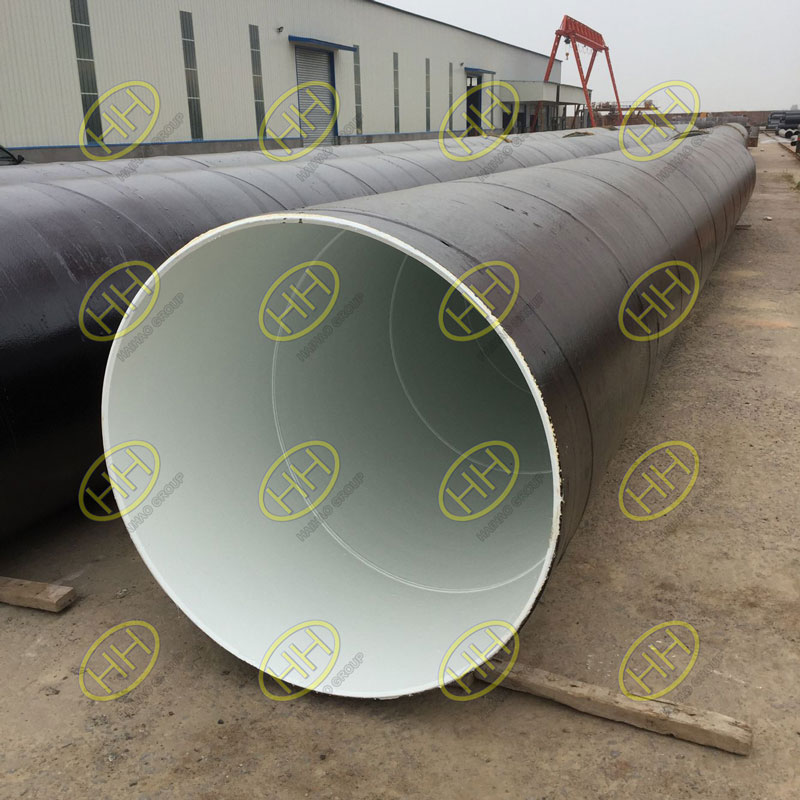

3PE anti-corrosion coating is a kind of anticorrosive coating for pipeline products. 3PE anticorrosion has three layers of polyethylene coating (MAPEC), which is composed of epoxy powder (FBE), adhesive (AD) and polyethylene (PE). It is widely used in pipe fittings, steel pipes, flanges and other pipeline products surface anti-corrosion, can prevent the rust of pipeline products effectively.

The advantages of 3PE anti-corrosion coating:

1.The 3PE coating adopts heat-shrinkable material, pipeline anticorrosive sealing, high mechanical strength, strong water resistance, stable quality.

2.The 3PE coating construction is convenient, its applicability is good.

3.The 3PE coating do not pollute the environment.

4.The 3PE coating low water absorption rate of PE, high strength of epoxy, good softness of hot melt adhesive, high anti-corrosion reliability.

Its disadvantages: the 3PE coating’s cost of is higher.

In Hebei Haihao Group, the 3PE coating is widely used in the production of flanges, pipe fittings, pipes and other pipeline products. It can effectively prevent the corrosion of products and extend the service life of products.Email:sales@haihaogroup.com