Haihao Group introduces you to gas metal arc welding (GMAW)

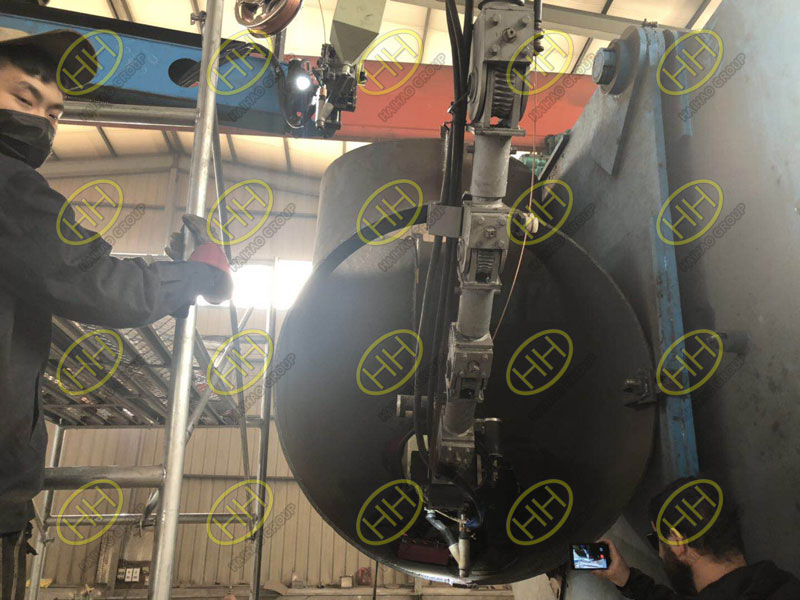

Haihao Group is a leading supplier in the field of pipeline systems. We are committed to providing customers with high-quality pipeline system supporting products and professional services. We have an experienced and skilled welding team who are proficient in various pipeline welding technologies and can meet various customer needs. This article will introduce you to gas metal arc welding (GMAW).

Welding Principle Gas Metal Arc Welding (GMAW) is a welding method that utilizes the heat generated by an arc between a continuous wire electrode and the workpiece to melt the metal. During the welding process, the arc melts the wire and the base metal, forming a weld pool and weld area. This process occurs under the protection of inert or active gases, effectively preventing the harmful effects of surrounding atmospheric air.

GMAW can be classified into semi-automatic and automatic welding. In semi-automatic GMAW, the welding gun is manually manipulated while the wire is fed into the weld pool by a wire feeder. In automatic GMAW, the welding gun movement is mechanized. When argon gas is used as the shielding gas, it is referred to as Gas Metal Arc Welding (GMAW). This method is suitable for welding materials such as carbon steel, low-alloy steel, heat-resistant steel, low-temperature steel, stainless steel, and is commonly used for welding aluminum and its alloys. When carbon dioxide gas is used as the shielding gas, it is called Gas Metal Arc Welding (GMAW) with CO2 shielding, also known as Metal Active Gas (MAG) welding. GMAW with CO2 shielding can be further classified into solid wire and flux-cored wire welding. Solid wire GMAW is suitable for welding low carbon steel and low-alloy steel, while flux-cored wire GMAW (FCAW) can weld not only carbon steel and low-alloy steel but also heat-resistant steel, low-temperature steel, stainless steel, among others.

The main welding parameters for GMAW include wire selection, welding current, arc voltage, welding speed, wire extension length, gas flow rate, type of power source, and polarity.

Welding Characteristics GMAW is a type of welding process that produces a visible arc during welding, making it easy to detect problems and make timely adjustments. Generally, there is no need to use tubular wires in the welding process, so there is no slag formation during welding, eliminating the need for slag removal after welding and reducing welding costs. GMAW has a wide range of applications, high production efficiency, and is suitable for all-position welding, as well as mechanization and automation. However, GMAW has limitations, including the use of a visible arc and high current density during welding, making it unsuitable for welding in windy conditions or outdoors. Additionally, the equipment required for GMAW is relatively complex.

GMAW is suitable for welding most metals and alloys, especially carbon steel, low-alloy steel, stainless steel, heat-resistant alloys, aluminum and its alloys, copper and its alloys, and magnesium alloys. For high-strength steel, superaluminum alloys, copper alloys with high zinc content, cast iron, austenitic manganese steel, titanium, titanium alloys, and high-melting-point metals, preheating of the base metal and post-weld heat treatment are required when using GMAW. Specialized welding wires and strict control of shielding gas are also necessary. However, GMAW is not suitable for low-melting-point metals such as lead, tin, and zinc, nor is it suitable for welded coated steel plates.