Production method of seamless steel pipe applied to FPSO ships

According to different production methods,the seamless steel pipe applied in FPSO can be divided into hot rolled pipe,cold rolled pipe,cold drawn pipe and extruded pipe.Here is a detailed description of these methods:

Hot rolling seamless pipe is generally produced on the automatic pipe rolling unit.The solid pipe billet is inspected and cleared of surface defects,cut to the required length,centralize the perforated end face of the pipe billet,and then sent to the heating furnace for heating and perforating on the puncher.Under the action of the roller and the top,a cavity is formed inside the billet,which is called capillary pipe.Send to the automatic rolling mill to continue rolling. Finally,the whole machine through the whole wall thickness,through the sizing machine diameter,to meet the specifications.It is an advanced method to produce hot-rolled seamless steel pipe by continuous pipe mill.

To obtain smaller size and better quality seamless pipe,cold rolling,cold drawing or both methods must be used.Cold rolling is usually carried out on a two-high rolling mill.The steel pipe is rolled in a circular groove with variable section and a fixed conical head.Cold drawing is usually carried out on 0.5 ~ 100T single chain or double chain cold drawing machines.

The extrusion method puts the heated tube billet in an airtight extrusion cylinder,and the perforating rod moves with the extrusion rod to extrude the extrusion part from the smaller die hole.This method can produce smaller diameter steel pipe.

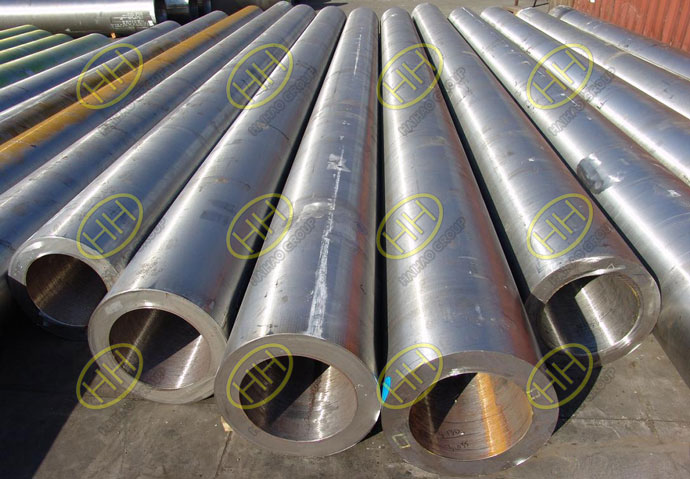

Hebei Haihao Group can produce various types of seamless pipes including carbon steel,stainless steel and alloy steel pipes for the construction,modification and maintenance of FPSO ships.If you want to know more about our seamless steel pipe applied to FPSO ships,please email us:sales@haihaogroup.com