Spiral submerged arc welded pipes (SSAW steel pipes)

Spiral submerged arc welded(SSAW) also know as submerged arc welded helical pipe(SAWH),its forward direction and forming tube centerline hose reel molding angle(adjustable),side molding edge welding and weld them into a spiral.

As we know,seamless steel pipe always is small dimension,longitudinal submerge arc weld steel pipe is large dimension,but for larger dimension,we should use the method of spiral submerge arc welding instead of longitudinal submerge arc welding.With this method,we can use narrow width steel plates to produce large dimension pipes.The outside diameter is determined by the angle of the de-coiled steel against the forming head. In this welding process, the material is submerged under a bed of fusible flex, which becomes conductive when heated. The resulting weld is sound, uniform and corrosion resistant, with a deep weld penetration.It is a high-speed,automated process that is used for long straight welds and is effective for thin sheets of metal.

Specification of spiral submerged arc welded pipes (SSAW steel pipes):

| Out Diameter | 219.1 mm-3048mm (8″-120″) |

| Wall Thickness | 6mm-25.4mm |

| Length | 2m/3m/4m/5.8m/6m/8m/9m/12m and other length required by customers |

| Standard | ASTM A53,ASTM A312,ASTM A333,ASTM A252,API 5L PSL1/ PSL2,API 5CT,EN10217, EN10219,BS,JIS,ISO,etc |

| Steel Grade | ASTM A53: GR A, GR B, GR C, GR D ASTM A312: GR TP304,TP316,TP321,TP347 ASTM A333: GR 3,GR 6 ASTM A252 GR 1, GR 2, GR 3 API 5L PSL1/ PSL2: GR A,GR B,X42,X46, X56, X60,X65,X70 API 5CT: H40,J55,K55,N80,N80-Q,R95,M65,L80,L80-9Cr,L80-13Cr,C90,T95,C110,P110,Q125 BS 4360: Grade 43, Grade 50 EN:S275, S275JR, S355JRH, S355J2H |

| Surface | Fusion bond epoxy(FBE) coating,coal tar epoxy,3PE,varnish coating,bitumen coating,black oil coating,galvanized,and as per customer’s requirement |

| Test | Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test, Exterior Size Inspection, Hydrostatic Test, X-ray Test |

| Package | Bags,bundles,PVC packing,carton packing,wooden case,or as customer request |

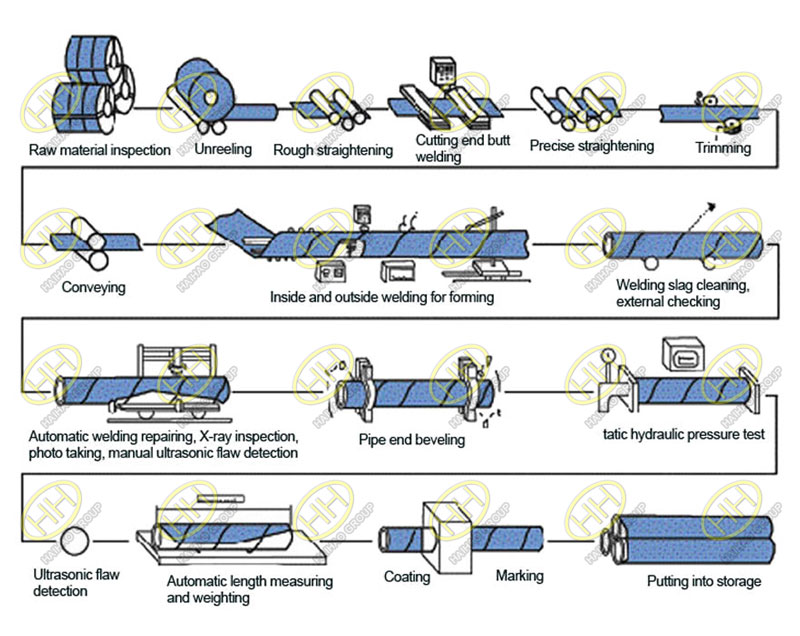

Manufacturing process of spiral submerged arc welded pipes (SSAW steel pipes):

Haihao Group has 9 spiral submerged arc welded(SSAW) producting lines,the whole machine line has high level antomation,sample operation and stable welding quality.Inside and outside welding bead use the AC/DC double wire technology of submerged arc welding to ensure the interior and exterior quality.If you want to know more about our piping products(seamless/welded steel pipes,butt welding/forged pipe fittings,flanges),please email us:sales@haihaogroup.com