What is the stamping and welding elbow?

The stamping and welding elbow, it is the use of the same material as the pipe material plate with stamping die stamping into a half ring elbow, and then the two half ring elbow group welding forming. Because of its good comprehensive performance, it is widely used in chemical engineering, construction, water supply, drainage, oil, heavy and heavy industry, refrigeration, sanitation, plumbing, fire, electricity, aerospace, shipbuilding and other basic engineering.

Its advantages:

(1) Stamping processing of high production efficiency, and easy to operate, easy to achieve mechanization and automation. Because stamping is to rely on stamping die and stamping equipment to complete the processing, ordinary press stroke times for every minute up to dozens of times, high speed pressure to every minute up to hundreds or even thousands of times, and each stamping stroke may get a stamping piece.

(2) The stamping generally no chip material generation, material consumption is less, and do not need other heating equipment, has the advantages of material saving, energy saving, so the cost of stamping elbow is lower.

(3) The stamping can be processed into a larger size range, more complex shape of parts, product size from small to large can be produced. And stamping materials will have cold deformation hardening effect, stamping strength and stiffness are higher.

(4) Stamping because the mold to ensure the size and shape of stamping parts precision, and generally do not destroy the surface quality of stamping parts, and die life is generally longer, so it has the characteristics of stable quality and good interchangeability.

The advantages of the production process of large stamping elbow mainly include the following aspects:

(1) Don’t need the tube billet as raw material, can save the cost of pipe equipment and mold, and can get arbitrary large diameter and relatively thin wall thickness of the pusher elbow. This kind of stamping elbow material is special, do not need to add raw materials, in the processing of easy to control.

(2)The blank for processing stamping elbow is flat plate or developable surface, so it is simple to cut, easy to ensure the accuracy, easy to assemble and weld, easy to control the raw materials during processing, simple operation, no complex process, and welding and assembly is more convenient.

(3)The production efficiency is high, can shorten the manufacturing cycle, the production cost is greatly reduced.

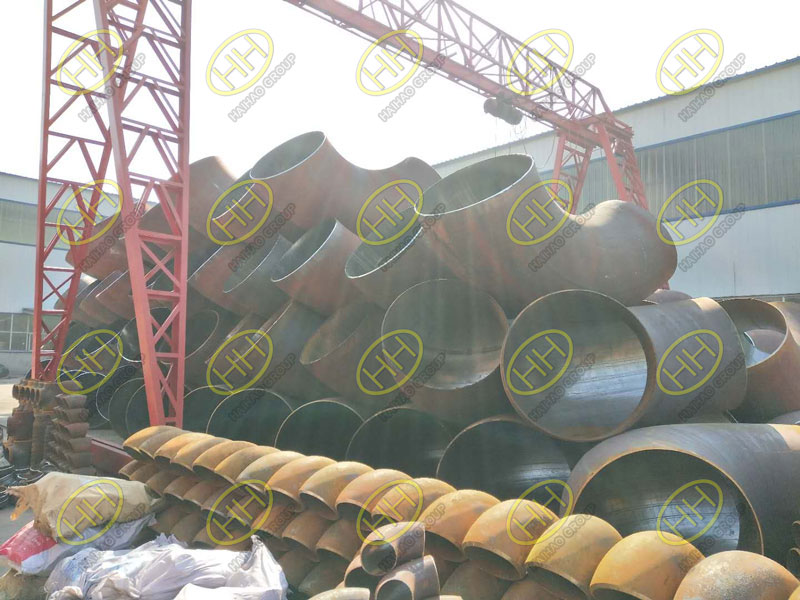

Hebei Haihao Group as a professional production and supplier of steel pipe, pipe fittings, flanges and other pipeline products, for the production of stamping elbow, we have complete equipment, die and mature technology.