-

In the realm of pipeline integrity, NACE MR0175 stands as a critical standard for ensuring the durability and safety of pipeline systems in environments prone to hydrogen sulfide stress cracking (HSSC). Understanding this standard and the principles behind ...

-

Electrical spark testing is a crucial method utilized for inspecting the quality of anti-corrosion coatings on metal substrates, particularly in the context of metal pipelines. This sophisticated technique is primarily employed to detect defects such as pi ...

-

In the shipping industry, reliability and quality assurance are of paramount importance. At Haihao Group, we understand the importance of meeting strict standards, so we are proud to introduce our RINA 3.2 marine service tested pipe fittings. RINA (Registr ...

-

Haihao Group proudly announces the successful dispatch of a substantial order to our esteemed client in the United Kingdom. This shipment comprises a comprehensive range of pipe fittings meticulously crafted to meet industry standards and customer specific ...

-

In the dynamic landscape of international commerce, delivering quality products on time and in pristine condition is paramount. Haihao Group, renowned for its commitment to excellence, is once again stepping up to ensure a seamless pipeline products delive ...

-

In any industrial application, the selection of non-destructive testing (NDT) methods plays a crucial role in ensuring safety, reliability, and efficiency. Here are the key principles to consider when choosing NDT methods: Understanding Method Capabilities ...

-

In the realm of steel materials, precision and adherence to standards are paramount. When it comes to the specific requirements for ASTM A350 LF2 CL.1, our commitment to excellence shines through. Let’s delve into the precise demands of our esteemed ...

-

Flange gaskets play a critical role in ensuring leak-free and safe connections in industrial piping systems. However, achieving effective sealing involves a delicate interplay of various factors. Let’s delve into the nuanced factors that influence fl ...

-

Flange nuts are a type of nut with a wide flange on one end, serving as an integrated washer. Made of hardened steel and zinc-coated, flange nuts find applications in various settings, depending on the purchased style. They typically feature a hexagonal sh ...

-

As an expert in the field of pipeline systems, Haihao Group has always put quality first and provides customers with high-quality products and services. Recently, a British customer requested magnetic particle testing when ordering EN 10253-2 P265GH tee pr ...

-

Haihao Group has always been committed to providing customers with high-quality pipeline system products. We are well aware of the importance of raw material market conditions for customers’ purchasing decisions. Therefore, we share weekly changes in ...

-

In the intricate world of piping systems, efficiency, and precision are paramount. At Haihao Group, we pride ourselves on delivering top-notch solutions that meet the exacting needs of our clients. Our latest offering, the ASME B16.9 ASTM A815M concentric ...

-

ASTM A420 WPL6 carbon and alloy steel pipe fittings meeting Singapore client’s material requirements

At Haihao Group, we take pride in our commitment to meeting the specific material requirements of our clients, ensuring the highest quality standards are met for every project. Recently, we had the privilege of working with a valued client from Singapore, ... -

In recent years, Haihao Group has achieved certifications from multiple classification societies such as ABS, DNV, BV, RINA, RS, and more. With our pipeline system products increasingly being utilized in the piping systems of large vessels, we are keenly o ...

-

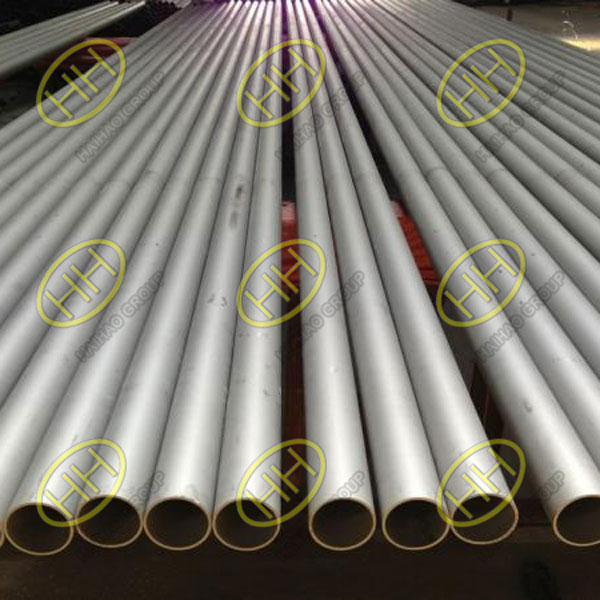

In the realm of industrial pipelines, precision, reliability, and durability are paramount. One standout product that embodies these qualities is the A106B carbon steel seamless pipe. Let’s delve into the specifics and features that make this produc ...

-

EN 10253 butt welded fittings play a pivotal role in various industries, adhering to stringent standards for understanding EN 10253 butt welded fittings quality and performance. This standard, classified into three parts, ensures the reliability and consis ...

-

In the field of complex piping systems, choosing the right branch pipe connections is crucial. The products ordered by Turkish customers from Haihao Group include sockolet and weldolet products. Let’s take a look at the differences between these two ...

-

Seamless steel pipes are essential components in various industries, each designed for specific applications and environments. Understanding the different materials available for seamless pipes is crucial for optimizing performance and reliability. LetR ...

-

Haihao Group recently carried out magnetic particle testing on a batch of carbon steel pipe fittings for our valued customer in the UK. Magnetic particle testing is a critical non-destructive testing method essential to ensuring the quality and integrity o ...

-

At the beginning of the new year, Haihao Group successfully delivered the screwed pipe fitting products ordered by customers in Pakistan. We are always committed to quality and precision to meet the precise requirements of our customers. Customers ordered ...