-

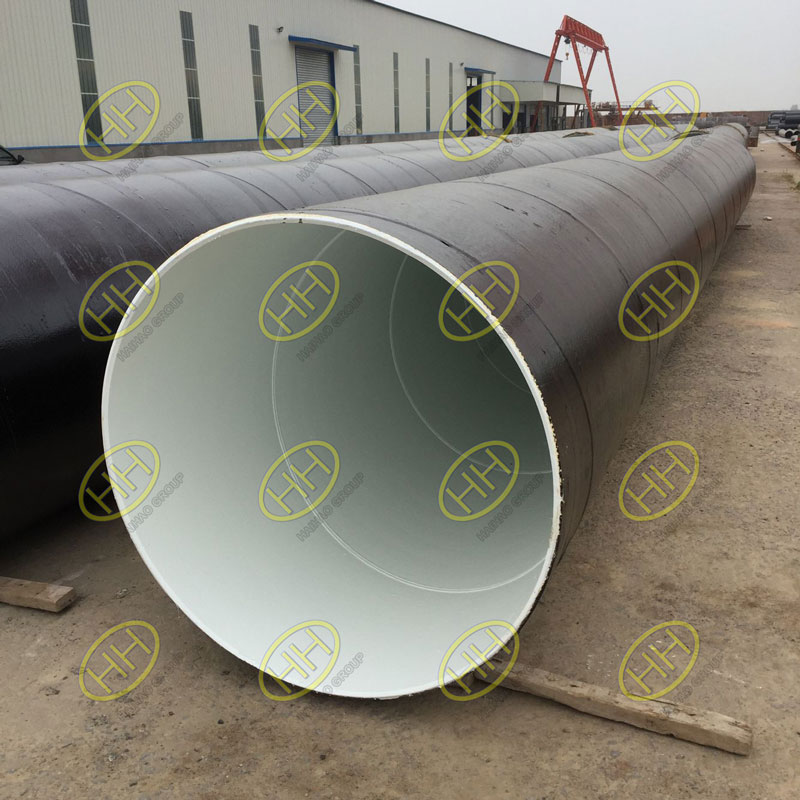

The main components of epoxy resin coating are epoxy resin and curing agent. Epoxy resin is a material with high strength, high hardness, and high corrosion resistance, while curing agent is a chemical substance that promotes the curing of epoxy resin. Whe ...

-

At Haihao Group, we understand the critical importance of protecting pipe fittings from extreme heat and ensuring their long-term durability and performance. That’s why we have partnered with leading coating factories to offer a wide range of high-qu ...

-

At Haihao Group, we take pride in being more than just a supplier of premium pipe fittings. We are dedicated to offering comprehensive solutions to meet all of our customers’ needs. Recently, we had the opportunity to assist a valued customer from th ...

-

In the fast-paced world of the oil and gas industry, efficiency and reliability are crucial factors for success. When it comes to designing and constructing pipelines, choosing the right components is of paramount importance. One such essential component i ...

-

Haihao Group takes immense pride in delivering top-quality pipe fittings to clients worldwide, and our recent shipment to Singapore further solidifies our commitment to excellence. We are thrilled to announce the successful delivery of a batch of premium f ...

-

When it comes to achieving optimal connections, Haihao Group understands that one size does not fit all. That’s why we offer a wide range of products with tailored thread shapes to meet the unique needs of our customers. Whether it’s tapered th ...

-

We are thrilled to announce the successful shipment of our high-quality concentric reducers to our valued customer in Turkey. With our commitment to excellence and customer satisfaction, we take pride in delivering superior products that meet industry stan ...

-

In the world of pipe fittings production, the quality of raw materials is paramount in ensuring the excellence of the final products. At Haihao Group, we understand the significance of sourcing high-quality materials, which is why we forge partnerships wit ...

-

We are delighted to present the remarkable production process behind the BS 1965 EN 10253-4 S235JRG2 reducing tee, specifically designed and manufactured to meet the highest industry standards. With our meticulous attention to detail and commitment to exce ...

-

In the world of pipeline systems, seamless flow and efficient transitions are vital for optimal performance. Behind the scenes, the manufacturing process of concentric reducers plays a pivotal role in achieving these objectives. In this promotional article ...

-

In the world of piping systems, durability and longevity are vital considerations. At Haihao Group, we understand the importance of safeguarding your piping components against the harsh elements and corrosive environments. That’s why we offer galvani ...

-

In the world of piping systems, adherence to industry standards is paramount to ensure compatibility, reliability, and safety. One such essential standard is ANSI B16.28, which specifically addresses the requirements for wrought steel butt-welding short ra ...

-

When it comes to piping projects, selecting the appropriate fittings is crucial for ensuring optimal performance and efficiency. One common decision that engineers and project managers face is whether to use a short radius elbow or a long radius elbow. Und ...

-

When it comes to piping systems, selecting the right fittings is crucial to ensure optimal performance and efficiency. Two commonly used elbow fittings are short radius elbows and long radius elbows. While both serve the purpose of changing the direction o ...

-

Not long ago, a customer from the UK ordered a batch of ASTM A234 WPB carbon steel elbows from our company. This batch of products was used in a chemical project in the UK. According to the needs of the customer, we recommended the appropriate coating type ...

-

At Haihao Group, we take great pride in producing high-quality pipe fittings, including the ASTM A234 WPB 40-inch carbon steel elbows. With a relentless focus on precision and craftsmanship, we ensure that our elbows meet and exceed industry standards. In ...

-

When it comes to pipeline systems, it’s essential to understand that not all pipelines are created equal. The specific requirements and challenges posed by different types of fluids necessitate distinct approaches in material selection, coating, desi ...

-

When it comes to flange steel pipe joints, ensuring a secure and leak-free connection is of utmost importance. One critical aspect of achieving this is the proper treatment of welding seams. At Haihao Group, we take pride in our expertise in providing top- ...

-

We are thrilled to announce that Haihao Group has successfully completed the galvanization process for the flanged steel pipe joints ordered by our valued customers. Galvanizing these products is a critical step that significantly enhances their durability ...

-

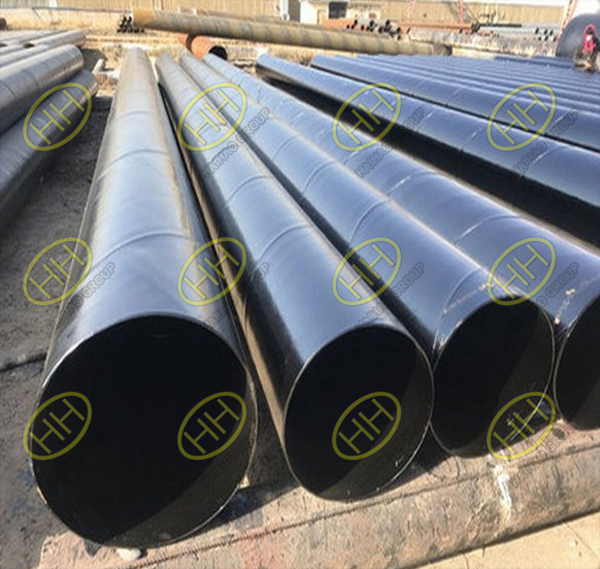

Steel pipes are widely used in various industries, including oil and gas, construction, and manufacturing. To ensure their durability and longevity, proper coating is essential. Coating not only protects the steel pipes from corrosion and rust but also imp ...