-

As an enterprise dedicated to providing customers with one-stop pipeline engineering products and services, Haihao Group not only has rich pipeline supporting products, but also has the ability to provide customers with coating treatment and engineering so ...

-

Valve is a widely used equipment, which can be found almost anywhere. It is active in the streets, houses, power plants and paper mills, refineries and various infrastructure and industrial facilities. In recent years, Haihao has gradually and increasingly ...

-

The function of the reducer is to make the pipe diameter change. From the direction of fluid movement, most of them change from large to small, and some of them change from small to large. For example, the reducer of steam return pipe and sewer pipe change ...

-

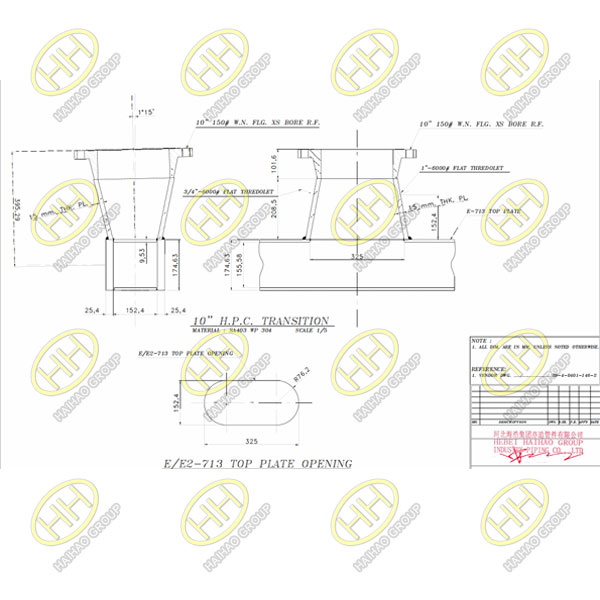

Due to the special marine environment, the products used on FPSOs often have higher quality requirements. It is necessary to take into account various factors such as the changeable weather on the sea, sea water corrosion, sea water impact and so on. There ...

-

Not long ago, the world’s largest natural gas processing FPSO that Haihao participated in the supply completed the trial run. In this cooperation, Haihao has fully demonstrated its professional level. When ordering flanges and other products, the cus ...

-

Endeavour for 40 years, passion for the future. In 1982, Hebei Haihao Group officially established its factory in Mengcun County, the hometown of pipe fittings in China. From a few people to more than 700 people, Haihao has always put product quality and s ...

-

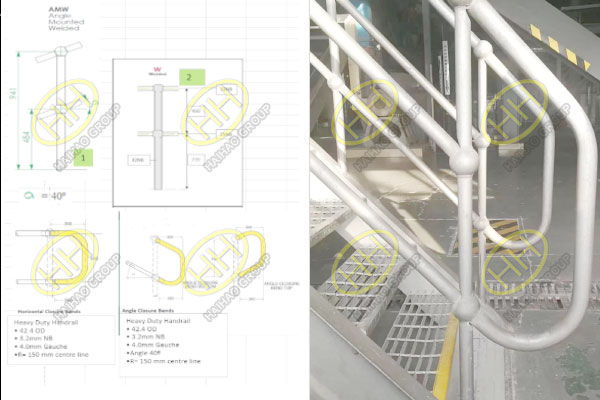

The following is a set of product drawing provided by British customers, it may be a railing for stairs. We are good at prefabricated goods, so we are very willing and professional to produce these drawing products. Drawing for prefabricated product Stanch ...

-

Rumaila Oilfield is located 50 kilometers west of Basra in southern Iraq. It is a giant oilfield, ranking sixth in the world. The amount of external procurement is very large every year. Our company supplies oil, gas, shipbulding, water treatment and other ...

-

Our company specialized in producing flanges and pipe fittings. It is also a professional work for us to weld fittings and flanges together. In addition, prefabricated products are also our advantages. We often produce some non-standard products according ...

-

The year 2023 is approaching us with vigor and vitality. In the New Year, Haihao Group will stay true to its original intention and forge ahead, working hand in hand with you to create a better world. Haihao Group

-

The compression type fittings are a hydraulic system that connects different hydraulic components to form a closed loop, and it is a fitting for connection. The descriptions are similar: UNION TEE, EQUAL, COMPRESSION TYPE, STAINLESS STEEL GRADE 316, TUBE X ...

-

This month Indian client two orders it’s ready to ship! One it’s A234 WPB seamless butt weld elbow and reducer! Another it’s stainless A403 WP316 elbow and tee! This year I got many inquiries from this client, of course the order quantity ...

-

The pipe tee is mainly used for the transmission of liquid and gas in the pipe network. In the three openings of the pipe tee, there is generally one inlet and two outlets or two inlets and one outlet. It is a kind of chemical pipe fittings, including T ty ...

-

Stainless steel tees can change the direction of the pipeline, and can be divided into equal tees and reducing tees. When using stainless steel reducing tees, they can also increase the pressure and speed of the substances flowing in the pipeline. Stainle ...

-

We all know that elbow is widely used in pipeline engineering, but the production and processing process of elbow is not so easy. There are relevant technical requirements for elbow processing. Now Haihao will show you these technical requirements. product ...

-

Today, the 2022 China Marine Economy Expo, the 2022 Shenzhen International Ocean Week and the 2022 Shenzhen Ocean Industry Investment Promotion Conference opened in Shenzhen. Haihao Group 9CT005 booth The Expo covers an exhibition area of 60000 square mete ...

-

Haihao Group will take many important products to participate in the 2022 China Marine Economy Expo held in Shenzhen Convention and Exhibition Center (Futian District) on November 24-26, 2022, to help China achieve the upgrading and development of pipeline ...

-

On November 18, CNOOC reported that China’s first self-developed shallow water underwater production system was successfully put into production in Jinzhou 31-1 Gas Field in Bohai Sea. This is an innovation in China’s shallow water oil and gas ...

-

2022 SSNAME Academic Conference The 2022 SSNAME academic conference was successfully held on November 12. The theme of the conference was “Innovation drives high-quality development of offshore engineering”, Haihao Group was honored to be invit ...

-

Due to the large diameter of large diameter elbow, direct pushing requires large pushing equipment, so both equipment technology and material cost are relatively high. Butt welding elbow and shrimp waist elbow are the most commonly used in the market. Let& ...