-

Stamping elbow is a good elbow, which has been widely used and promoted in different fields and industries. The stamping elbow is formed by the same die as the pipe, and then the two half ring elbows are welded in batches. Due to the different welding stan ...

-

My Korean client Mr. Park inspected the order at our factory from May 25 to 31. During this period, I accompanied Mr. Park to carry out the inspection. We prepared a lot of inspection tools, some of which we bought new, and no customer or third party had a ...

-

Forging is a workpiece or blank obtained by forging and deforming a metal blank. The mechanical properties of metal billet can be changed by applying pressure to make it produce plastic deformation. The looseness of metal can be eliminated by forging. Hole ...

-

As a developing country, Serbia has witnessed rapid economic growth in recent years, which has been called “the tiger of the Balkans” by some people. All aspects need to be built of this country. WELD NECK FLANGES EN 1092-1 P235GH Electricity i ...

-

Tee is a pipe fitting and pipe connector, which is used in the branch pipe of main pipeline. There are two kinds of tee: equal tee and reducing tee. Named because the three ends can be connected to the pipe. Recently our factory produce some thick wall tee ...

-

The chemical polishing is a common polishing method for stainless steel products. Chemical polishing generally uses nitric acid or phosphoric acid and other oxidizing agent solution, under certain conditions, make the surface of stainless steel products ox ...

-

Tariffs on some steel products will be adjusted from May 1, 2021, according to a notice posted on the website of the Ministry of Finance.Among them, pig iron, crude steel, recycled steel raw materials, ferrochrome and other products to implement zero impor ...

-

The stamping elbow is a kind of elbow pipe fittings. It has shown good performance in practical use at home and abroad. The basic forming process of stamping elbow is: the sheet metal with the same material as the pipe is pressed into a half annular elbow ...

-

Elbow is used for pipe bending, which accounts for a large part of all pipe fittings in the pipeline system, accounting for about 80%. At present, hot push, stamping and extrusion are commonly used forming process of seamless elbow. Hot push elbow forming ...

-

The welding of stainless steel pipes directly affects the quality and service life of stainless steel pipes.What should we pay attention to when welding stainless steel pipe? Here are the main matters need attention. 1.The use of vertical external characte ...

-

The quality of stainless steel tube is determined by the brightness of stainless steel tube after annealing. There are many influencing factors, and the following are the several main factors: 1.Whether the annealing temperature reaches the specified tempe ...

-

In pipeline industry,direct reading spectrometer is widely used to identify the materials.But except for the PMI,chemical analysis method is also often used.Then what is the advantages and disadvantages of chemical analysis method? Advantages of chemical a ...

-

ASTM A420/A420M-2016 “Fittings for Forged Carbon Steel and Alloy Steel Pipe for Low Temperature”, American Standard Low Temperature Seamless or Welded Pipe Fittings, the domestic corresponding material is A333 Gr.6, generally used in low temper ...

-

Heat treatment is a very important process in the production of pipe fittings. They can remove the stress of the pipe fittings or improve their hardness. For the pipe fittings, there are many kinds of material and they can be used all kinds of enviroment. ...

-

Teflon coating is a non-stick industrial coating with wear resistance, heat resistance, corrosion resistance and many other characteristics. At present, it is widely used as a coating for pipeline products. Teflon industrial coatings are available in powde ...

-

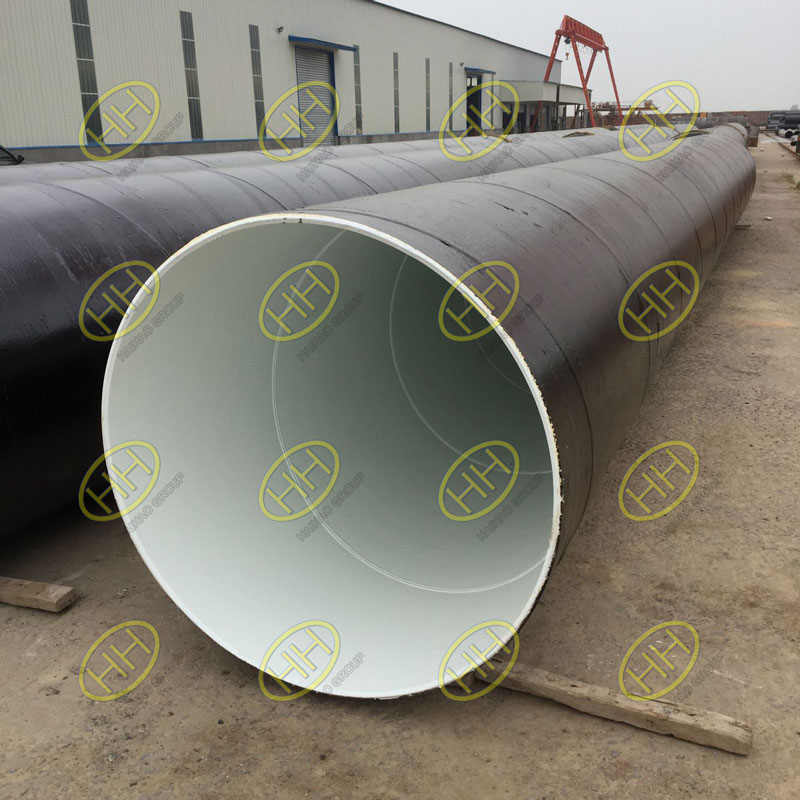

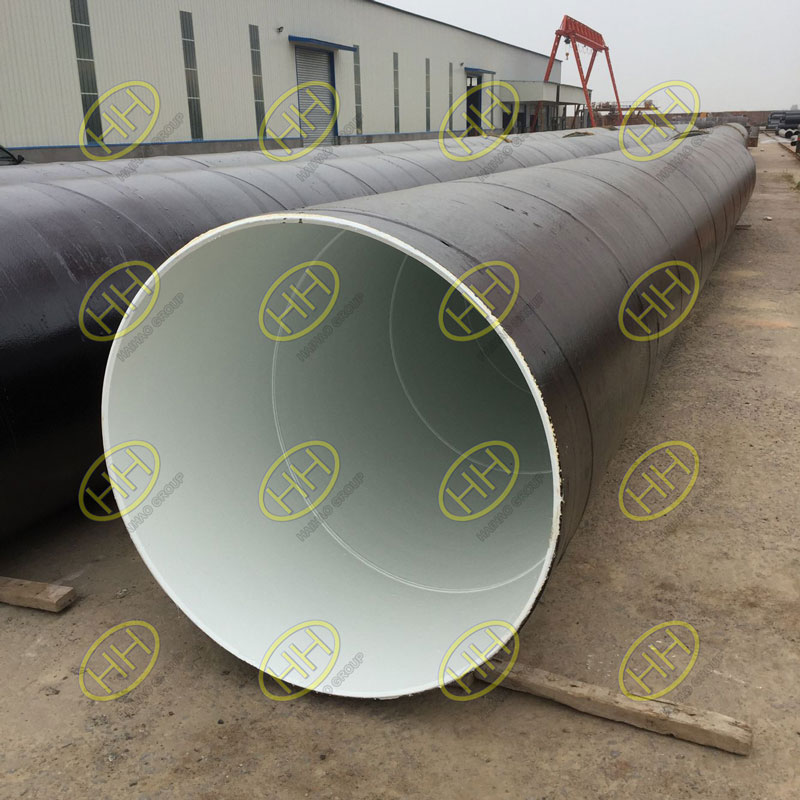

Hebei Haihao Group is a manufacturer specialized in producing flange, pipe fittings and steel pipe. When customer purchase steel pipe for pipeline systems, always we see the pipe has been asked for a epoxy coating FBE. Hebei Haihao Group can provide custom ...

-

Recently, our company received an order for steel pipes from Saudi Arabia, and the customer required the steel pipes to be coated with 3PE, Hebei Haihao Group is a professional production of steel pipe factory, to meet the different needs of customers. Tod ...

-

A few months ago, I received an inquiry from a customer in Singapore. The Main products in this inquiry include: (1) 90° Elbow LR Seamless 1.1/2″ to 8″ SCH40 and SCH80 ASME B16.9 (2) Concentric Reducer Seamless 2″*1.1/2″ to 8″ ...

-

Socket welded fitting is another kind of welded fitting compared with butt-welded fitting. The diameter of socket welded fitting is usually the small diameter-2 inches and below. The socket welded fittings are welded by fillet weld, which is more suitable ...

-

The pipe cap is a kind of pipe fitting installed on the external thread of the pipe end to block the pipe. The head is suitable for the upper and lower parts or left and right ends of the vessel equipment. Generally, the pipe cap is of outer diameter, such ...