-

Installing a wafer ball valve correctly is critical to ensuring its proper function, long-term reliability, and safety in pipeline systems. This guide outlines the key steps and precautions to follow during installation to maximize valve performance and se ...

-

Haihao Group is a reliable provider of industrial pipeline solutions. Recently, Haihao Group successfully completed a professional order for ASME B16.11 NPT threaded caps for a customer in the Singapore oil and gas industry. The 3/4-inch caps, rated for 60 ...

-

In pipeline systems, flanged connections are commonly used to ensure reliable sealing and secure assembly between pipe sections, valves, and equipment. One often overlooked but critical detail in this process is the correct exposure of bolt threads after t ...

-

In critical piping systems—especially those used in oil and gas, offshore, and petrochemical industries—material selection plays a key role in ensuring long-term performance, corrosion resistance, and regulatory compliance. Two materials that frequently ap ...

-

In industrial automation and process control systems, the choice between pneumatic and electric valves is a crucial decision that can significantly impact system performance, safety, and reliability. While both types of valves have their advantages, pneuma ...

-

Control valves play a critical role in regulating flow, pressure, and other variables in piping systems. However, certain types of control valves have inherent design characteristics that can lead to operational challenges. This article explores six common ...

-

When it comes to industrial pipe fittings and connections, understanding thread standards is essential. Pipe threads play a critical role in ensuring secure, leak-proof connections in piping systems across oil & gas, chemical processing, water treatmen ...

-

In Russia’s rugged energy frontier, where pipelines must endure sub-zero temperatures and high-pressure environments, Haihao Group delivers ASME B36.10 ASTM A333 Gr.6 seamless pipes engineered for Siberia’s harshest challenges. From Yamal Penin ...

-

April 15, 2025, Moscow – Day 2 of Russia’s premier oil and gas exhibition, NEFTEGAZ 2025, continues to electrify the Expocentre Moscow. Haihao Group, a global leader in industrial pipe fittings, flanges, and integrated pipeline solutions, is making w ...

-

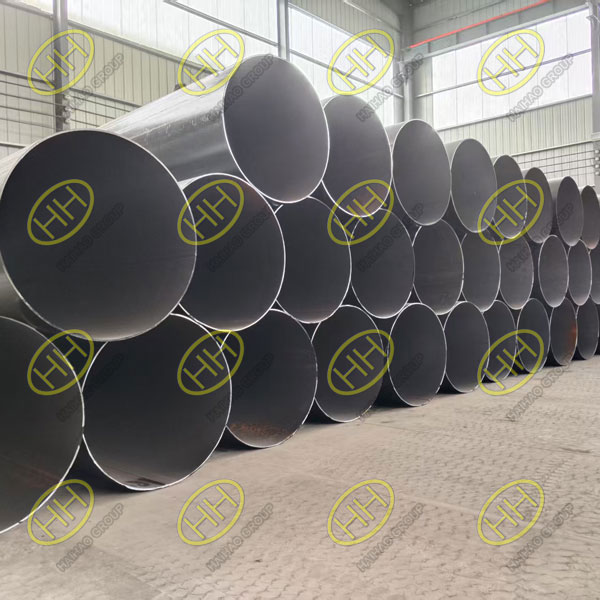

At Haihao Group, we are dedicated to delivering high-quality pipe solutions that meet the most demanding industrial standards. Our recent focus on the ASME B36.10M ASTM A53 Gr.B seamless pipes and ERW pipes has allowed us to provide exceptional products ta ...

-

At Haihao Group, we are dedicated to delivering high-quality pipe fittings and solutios that meet the most demanding industrial standards. Our recent focus on the MSS SP-95 ASTM A815 UNS S32750 swage nipple has allowed us to provide exceptional products ta ...

-

The 2025 NEFTEGAZ International Exhibition for Equipment and Technologies for the Oil and Gas Industries is just 4 days away! Haihao Group is excited to announce our participation in this premier oil & gas event, held from April 14 to April 17, 2025, a ...

-

In the field of industrial pipeline fabrication, the quality of welds is critical to structural integrity and service life. At Haihao Group, we understand that achieving high-quality welds requires a deep understanding of how welding current, voltage, and ...

-

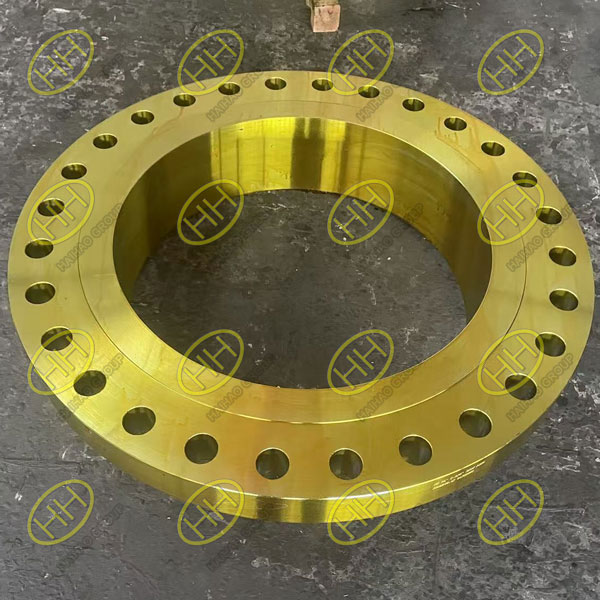

At Haihao Group, we recently completed a thorough quality inspection for a batch of high-grade pipeline components ordered by a client in Singapore. These products, designed for high-pressure and low-temperature industrial applications, demonstrate our tec ...

-

At Haihao Group, we are proud to introduce our high-quality seamless tube bends in stainless steel grades TP321 and TP304 for German customer. These products are designed to meet the rigorous demands of industrial applications while ensuring optimal perfor ...

-

ASTM A105 is a forged carbon steel material widely used for manufacturing flanges, fittings, and piping components in high-pressure and high-temperature environments. It is commonly used in oil & gas, petrochemicals, power plants, and refineries due to ...

-

Seamless pipe fittings, as defined by the ASME B16.9 standard, offer significant advantages over welded fittings. Unlike welded fittings that require joining processes which may introduce defects, seamless fittings are produced as a single piece, ensuring ...

-

Gate valves are essential components in fluid control systems, but sometimes their handwheel rotation becomes stiff or difficult, leading to operational failures. This issue can be caused by multiple factors, including mechanical wear, improper material se ...

-

When it comes to steel pipes, wall thickness plays a crucial role in determining their strength, pressure resistance, and suitability for various applications. There are multiple ways to represent pipe wall thickness, depending on industry standards and co ...

-

With less than a month remaining, the highly anticipated NEFTEGAZ 2025 exhibition is just around the corner! This prominent event, taking place in Moscow, Russia from April 14th to 17th, 2025, continues to solidify its position as one of the largest and mo ...