-

Flat washers are an essential component in the use of bolts and nuts, playing a crucial role in ensuring the integrity and durability of fastened joints. But how should you select the right flat washer for your needs? Here’s a guide to help you understand ...

-

Haihao Group recently dispatched a substantial shipment of ASME B16.9 SMLS concentric and eccentric reducers to our esteemed clients in Singapore. With sizes ranging from 3″ x 1.1/4″ to 14″ x 12″, these reducers, totaling over 450 u ...

-

Welding materials encompass various filler metals and additional protective substances used to enhance the quality of welding processes. Widely utilized in welding production, these materials primarily include welding rods, welding wires, fluxes, and more. ...

-

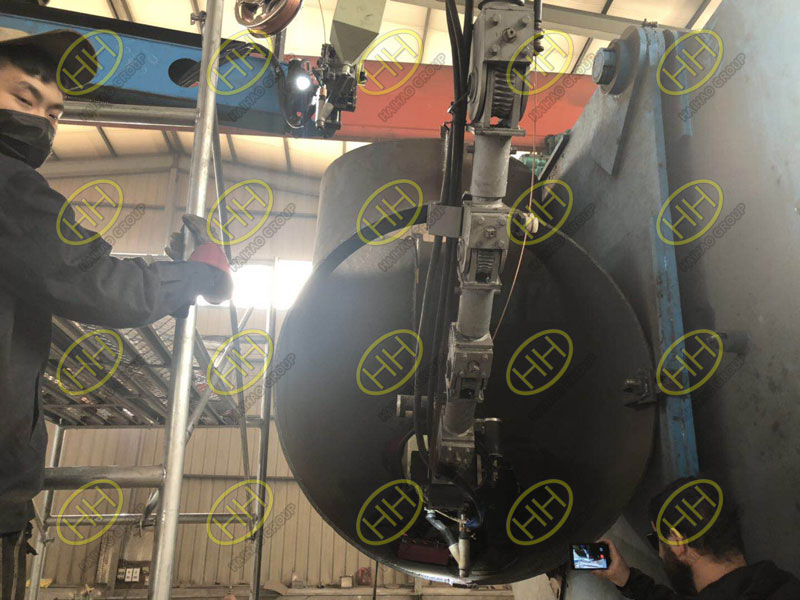

As an expert in the field of pipeline systems, Haihao Group not only produces and sells high-quality pipeline system supporting products, but is also proficient in various pipeline-related technologies, including welding and coating technologies. In the we ...

-

Haihao Group is a leading supplier in the field of pipeline systems. We are committed to providing customers with high-quality pipeline system supporting products and professional services. We have an experienced and skilled welding team who are proficient ...

-

As an expert in the field of pipeline systems, Haihao Group has rich practical experience in the selection of product materials and product processing. Not long ago, we produced pipe fittings for Russian customers that can be used at minus 196 degrees Cels ...

-

Metal pipeline welding methods can be classified into three main categories based on the nature of the weld metal joint: fusion welding, pressure welding, and brazing. Fusion welding involves heating the joint to a molten state without applying pressure to ...

-

Cold cracking poses a significant threat, often resulting in catastrophic consequences. While only a small fraction of pressure vessel accidents worldwide are due to design flaws or improper material selection, the vast majority are caused by brittle fract ...

-

Metallographic inspection utilizes the principles of quantitative metallography to establish a three-dimensional morphology of alloy structures through the measurement and calculation of the microstructure of two-dimensional metallographic samples or films ...

-

Material composition analysis is one of the methods to evaluate the chemical composition and content of a product to determine whether it meets quality standards. According to the operation method, material composition analysis can be divided into chemical ...

-

Bend testing evaluates the mechanical performance of materials under bending loads. It involves placing a specimen of defined shape and size on a bending device, bending it to a specified angle around a predetermined radius, and then examining its deformat ...

-

We are pleased to introduce to you a material analysis method for pressure pipes – instrumental analysis. This is an advanced analysis method based on the physical or physicochemical properties of substances. It obtains analysis results by measuring ...

-

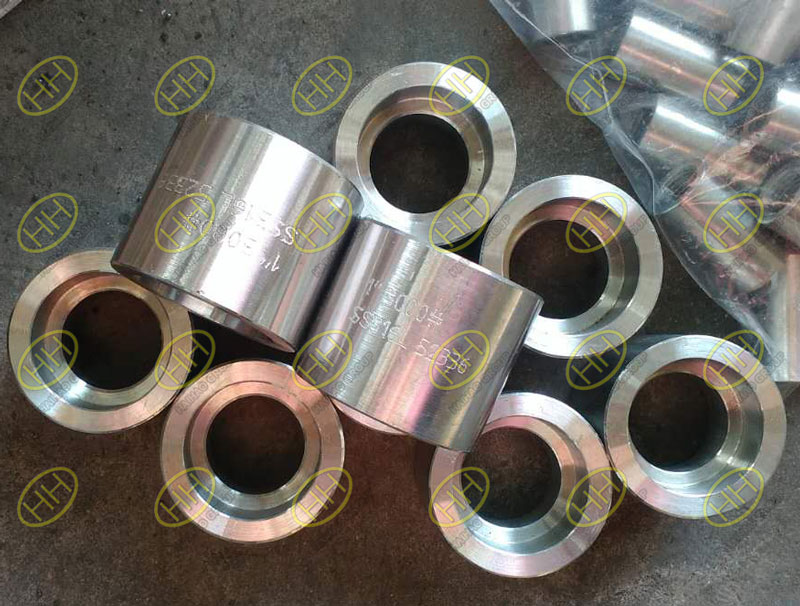

Haihao Group is pleased to introduce our wide range of stainless steel fittings, tailored to meet different standards, providing exceptional corrosion resistance and mechanical performance. Our products are meticulously crafted to ensure durability and rel ...

-

As an expert in the field of pipeline systems, HaiHao Group plays an increasingly vital role in the construction of international large-scale vessel pipeline systems. We are proud to announce that our pipeline system products are being widely applied in th ...

-

As a leading expert in the field of pipeline systems, Haihao Group prides itself on mastering various pipeline surface coating technologies to ensure the highest standards of protection and durability. One such innovative solution in our arsenal is the epo ...

-

Haihao Group takes pride in its ability to deliver a wide range of flange solutions tailored to the diverse needs of our customers. Recently, a domestic shipyard placed an order for a batch of blind flanges, encompassing various specifications and standard ...

-

Haihao Group is proud to announce the successful fulfillment of a large order from a well-known domestic shipyard, which marks another milestone in our pursuit of excellence in the field of piping systems. This comprehensive order covers a wide range of pr ...

-

In the realm of pipeline integrity, NACE MR0175 stands as a critical standard for ensuring the durability and safety of pipeline systems in environments prone to hydrogen sulfide stress cracking (HSSC). Understanding this standard and the principles behind ...

-

Electrical spark testing is a crucial method utilized for inspecting the quality of anti-corrosion coatings on metal substrates, particularly in the context of metal pipelines. This sophisticated technique is primarily employed to detect defects such as pi ...

-

In the shipping industry, reliability and quality assurance are of paramount importance. At Haihao Group, we understand the importance of meeting strict standards, so we are proud to introduce our RINA 3.2 marine service tested pipe fittings. RINA (Registr ...