-

Against the backdrop of the belt and road initiative, Haihao Group’s collaboration with our UAE partners has witnessed a remarkable surge in projects. At the beginning of this year, a longstanding UAE client, with whom we have had multiple successful ...

-

In our close collaboration with esteemed clients from the United Arab Emirates, we proudly introduce an exceptional coating technology that provides a fresh layer of protection for your bolts and nuts—Polytetrafluoroethylene (PTFE) coating. This high-perfo ...

-

Haihao Group, as a leading enterprise in the international market, continues to actively expand its overseas business, boasting a vast customer base. The frequent occurrence of clients placing additional orders highlights the trust and satisfaction in our ...

-

In recent years, with the growth of the Chinese economy and significant progress in the shipbuilding sector, Haihao Group, as a specialist in pipeline systems, has been actively expanding its presence in the field of marine pipeline engineering. Leveraging ...

-

The offshore oil industry has made great breakthroughs in China. Recently, data released by the National Energy Administration shows that domestic crude oil production will reach 208 million tons in 2023, of which offshore crude oil production will exceed ...

-

As the year 2024 unfolds, Haihao Group has been closely monitoring the changes in the domestic steel scrap market and would like to share recent market dynamics. Last week, the domestic steel scrap market continued its trend of relatively strong performanc ...

-

Not long ago, an order from a Singaporean customer included a butt-welded branch pipe stand. As an expert in the field of pipeline systems, Haihao Group not only provides reliable products, but is also proficient in various pipeline knowledge. The branch p ...

-

In recent years, Haihao Group has strengthened its collaboration with Slovakia, a crucial partner along the Belt and Road Initiative. Benefiting from favorable policies, the group has expanded its footprint in the country. Last year, a client from Slovakia ...

-

Driven by the “Belt and Road” policy, Haihao Group’s trade relations with Iraq have continued to increase. As a strategic reserve supplier of PetroChina, many of these projects are carried out in cooperation between Haihao Group and PetroChina. ...

-

In a recent collaboration, valued customers in Pakistan chose superior quality and thus selected a range of top-notch pipe fittings offered by Haihao Group. We are committed to providing solutions that meet and exceed expectations, taking pride in superior ...

-

Haihao Group has been engaged in the field of pipeline system supply for more than 40 years. Our pipeline system products, flanges, elbows, tees, steel pipes and other products are widely used in pipeline systems around the world. In order to bring custome ...

-

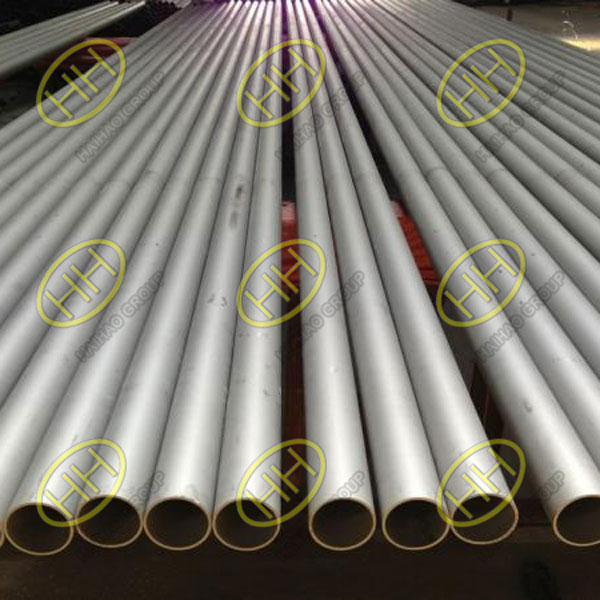

Haihao Group’s Italian customer placed an order for seamless steel pipes of various materials, one of which is basic oxygen converter steel ASTM A106 Grade B. This exceptional material selection reflects our commitment to delivering best-in-class qua ...

-

In steel production, the melting method plays a crucial role in the quality and properties of the final steel product. In the order from the Iranian customer, the customer requested that the material of the seamless steel pipe be smelted using an electric ...

-

Haihao Group, an expert in the field of pipeline systems, not only offers a variety of large-scale pipeline products such as flanges, elbows, and tees but also commits to producing high-quality bolts and nuts for pipeline systems. We understand the specifi ...

-

Haihao Group is delighted to announce the successful provision of an outstanding range of pipeline system products to our esteemed Japanese client. This recent order encompasses various specifications and models, showcasing Haihao Group’s manufacturi ...

-

Recently, the 2023 National Petroleum and Chemical Technology Innovation Conference was held in Wuhan, where the China Petroleum and Chemical Industry Federation presented the 2023 Science and Technology Awards. PetroChina garnered an impressive 82 technol ...

-

Haihao Group maintains a strong collaborative relationship with COSCO Shipping Heavy Industry in maritime engineering. Currently holding certifications from major classification societies such as ABS, DNV, BV, RINA, our pipeline system products find extens ...

-

For years, Haihao Group has been the mainstay in the forging field and is committed to mastering advanced forging technology. Not long ago, a forging project in Russia in which we collaborated with China National Petroleum Corporation was underway. We take ...

-

As Serbia continues to be a crucial partner in the Belt and Road Initiative, trade relations with China have significantly intensified in recent years. In line with this trend and driven by supportive policies, Haihao Group has actively engaged in numerous ...

-

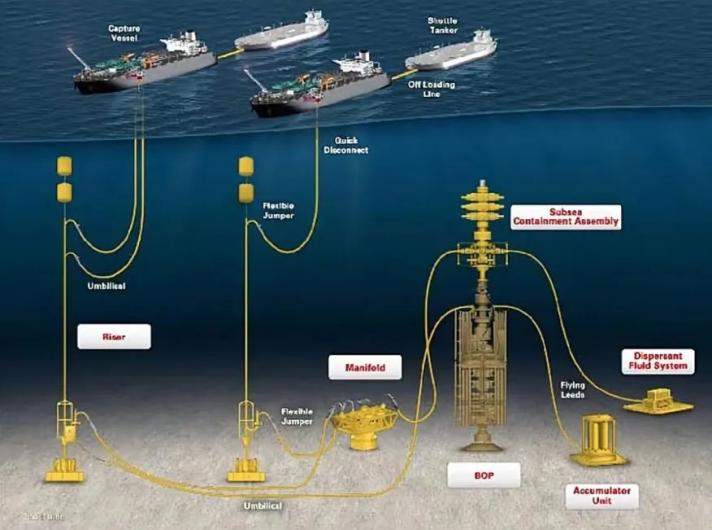

The vast expanse of the ocean floor holds abundant resources such as oil, gas, and minerals. Extracting these valuable commodities requires a complex process of underwater development, followed by long-distance transportation to the mainland. Throughout of ...