-

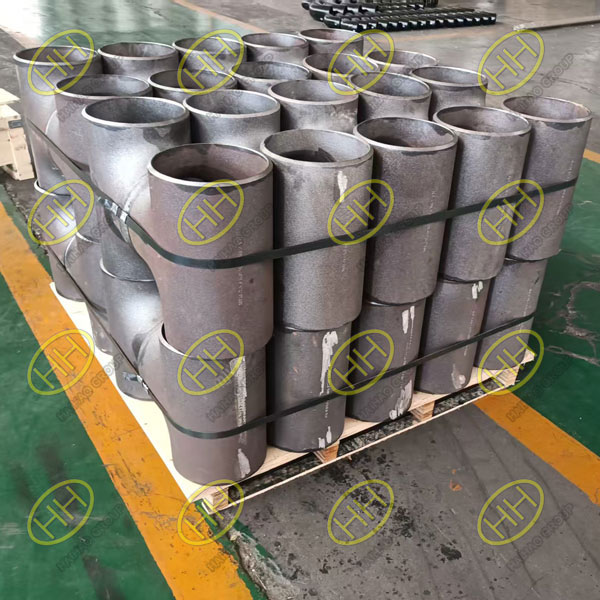

Haihao Group recently completed the shipment of a large order of seamless carbon steel pipe fittings to a client in Brazil, supporting a critical pipeline infrastructure project. The order includes a wide range of components manufactured in accordance with ...

-

Haihao Group is pleased to announce the recent shipment of precision-engineered 90 degree long radius elbows to our valued customer in Singapore. These stainless-steel fittings were manufactured to ASME standards and custom-tested to ensure a perfect fit a ...

-

At Haihao Group, we supply forged rings made to meet our clients’ exact needs. Recently, we delivered a special order of forged rings to a customer in the United Arab Emirates. Custom Forged Rings Made to Client Drawings We produced these forged ring ...

-

Haihao Group has successfully completed the production and shipment of 45° long radius elbows to a valued customer in the United Arab Emirates, marking another milestone in our commitment to delivering customized, high-performance piping components to glob ...

-

As a leading manufacturer of forged fittings and flanges, Haihao Group recently completed the production of a batch of high-pressure stainless steel couplings for our valued customer in Indonesia. These components will be installed in critical piping syste ...

-

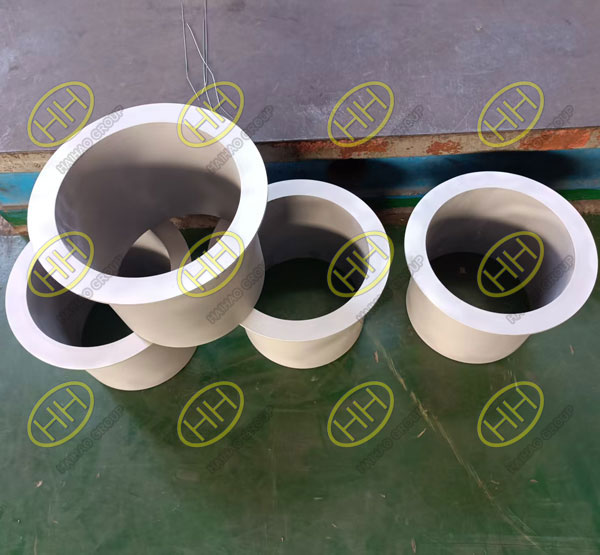

Recently, our workshop completed production of a batch of seamless stub ends tailored for a Russian customer with highly specific project requirements. This order demonstrated not only our capacity for precision manufacturing but also our experience in ful ...

-

Low-temperature pressure vessels play a crucial role in industries such as LNG storage, cryogenic chemical processing, and refineries, where materials are exposed to subzero conditions. The reliability and safety of these vessels depend largely on the sele ...

-

In industrial piping systems, precision, reliability, and compatibility are crucial—and that starts with choosing components that comply with international standards. Two of the most widely used specifications in the industry are ASME B16.9 and ASME B16.5, ...

-

Haihao Group has successfully completed the production and delivery of two batches of ASME B36.10 seamless alloy steel pipes, made from ASTM A335 Grade P5 (5Cr-0.5Mo alloy steel). These pipes were supplied to a valued domestic client and are intended for u ...

-

Earlier this month, we completed a shipment of stainless steel pipe fittings for one of our long-term clients in Russia. The order included two essential components: equal tees and 90-degree long radius elbows, both produced from ASTM A403 WP304L stainless ...

-

In the complex world of industrial piping, selecting the correct material for pipe fittings isn’t just about functionality—it’s paramount for pipeline integrity, safety, and long-term operational efficiency. Recently, Haihao Group delivered ASM ...

-

Haihao Group, a leading Chinese manufacturer of industrial pipe fittings, has successfully completed another high-quality delivery for a valued client in Australia. The order featured an extensive range of fittings, manufactured to international standards ...

-

As a leading industrial pipe fitting manufacturer integrating industry and trade capabilities, Haihao Group recently completed a strategic order for seamless equal tees for an Italian client in the energy sector. This case study highlights our expertise in ...

-

In the competitive global market for industrial pipe fittings, Haihao Group stands as a beacon of reliability and quality. As an integrated industrial and trading enterprise, we specialize in providing one-stop solutions for clients worldwide, from raw mat ...

-

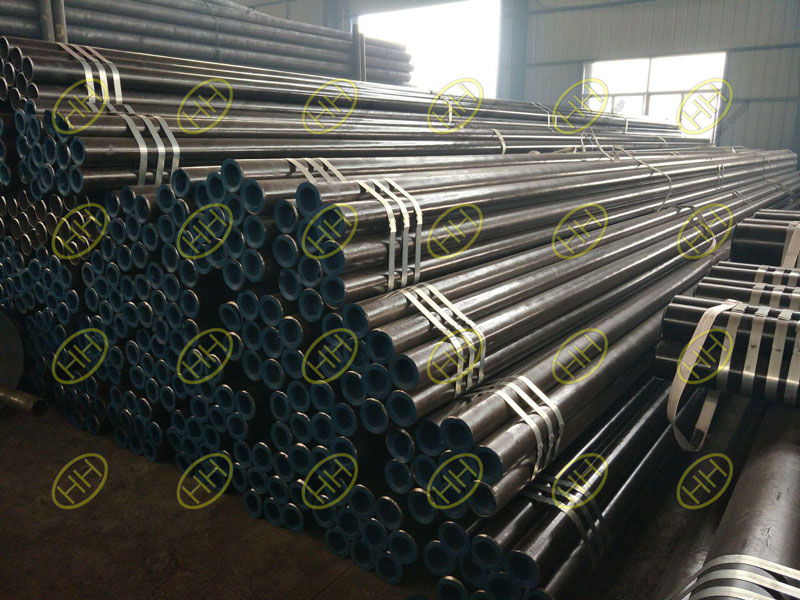

Recently, Haihao Group produced a batch of pipeline system products for a Singapore customer, including two types of steel pipes, API 5L Gr. B seamless steel pipe and SAW steel pipe. Both types of steel pipes follow the ASME B36.10 standard, but when deliv ...

-

For Australian engineering firms, pipeline projects demand precision, durability, and adherence to global standards. When a recent client required a 600NB X 300NB SCH STD reducing tee with specific customization, Haihao Group’s expertise in ASME B16. ...

-

When a Singaporean client needed robust, high-pressure pipe fittings for a critical project, they turned to Haihao Group. The result? A flawless order of ASME B16.11 A350 LF2 CL1 90° socket weld elbows and couplings (1″, 6000#), engineered to perfection an ...

-

Haihao Group has successfully fulfilled an order for ANSI B16.11 ASTM A105 sockolets from a Singaporean client, demonstrating our expertise in delivering high-pressure forged fittings for critical applications. The delivered components include: ANSI B16.11 ...

-

Haihao Group, a global expert in piping system solutions, has successfully delivered a batch of ASME B16.9 A815 UNS S31803 WP-S eccentric reducers to a Singapore client, earning their high praise. These eccentric reducers are meticulously crafted from UNS ...

-

15X5M, also known by its Russian designation 15Х5М, is a chromium-molybdenum alloy steel widely used in the manufacturing of pressure vessels, heat exchangers, and piping components operating under high pressure and elevated temperatures. This steel is par ...