-

The 2025 NEFTEGAZ International Exhibition for Equipment and Technologies for the Oil and Gas Industries is just 4 days away! Haihao Group is excited to announce our participation in this premier oil & gas event, held from April 14 to April 17, 2025, a ...

-

In the field of industrial pipeline fabrication, the quality of welds is critical to structural integrity and service life. At Haihao Group, we understand that achieving high-quality welds requires a deep understanding of how welding current, voltage, and ...

-

At Haihao Group, we recently completed a thorough quality inspection for a batch of high-grade pipeline components ordered by a client in Singapore. These products, designed for high-pressure and low-temperature industrial applications, demonstrate our tec ...

-

At Haihao Group, we are proud to introduce our high-quality seamless tube bends in stainless steel grades TP321 and TP304 for German customer. These products are designed to meet the rigorous demands of industrial applications while ensuring optimal perfor ...

-

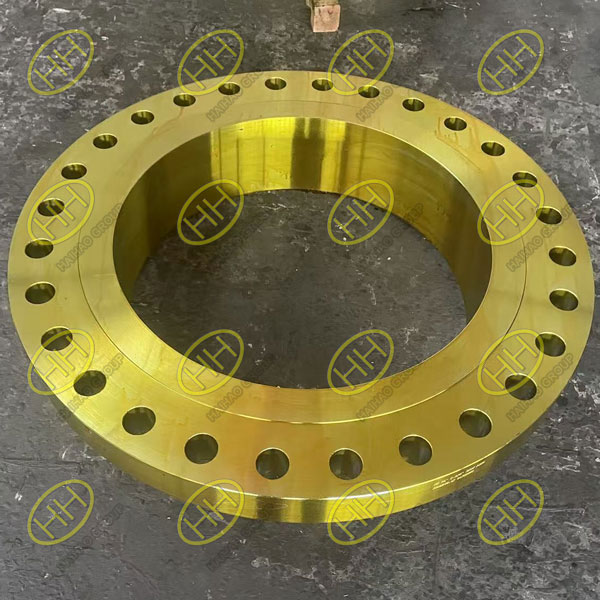

ASTM A105 is a forged carbon steel material widely used for manufacturing flanges, fittings, and piping components in high-pressure and high-temperature environments. It is commonly used in oil & gas, petrochemicals, power plants, and refineries due to ...

-

Seamless pipe fittings, as defined by the ASME B16.9 standard, offer significant advantages over welded fittings. Unlike welded fittings that require joining processes which may introduce defects, seamless fittings are produced as a single piece, ensuring ...

-

Gate valves are essential components in fluid control systems, but sometimes their handwheel rotation becomes stiff or difficult, leading to operational failures. This issue can be caused by multiple factors, including mechanical wear, improper material se ...

-

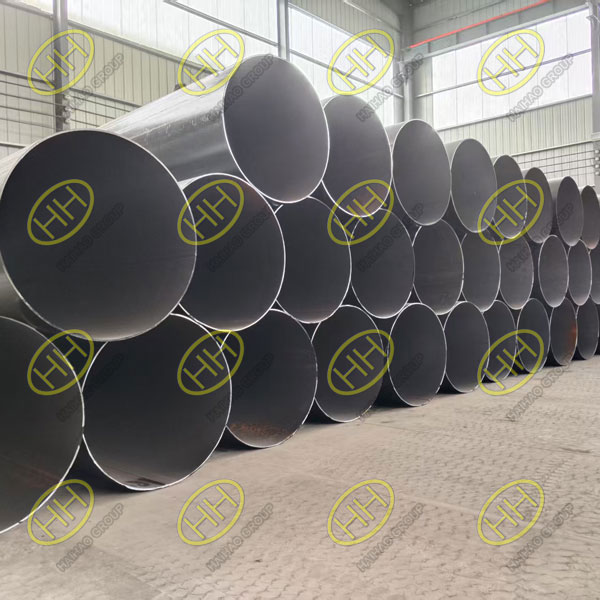

When it comes to steel pipes, wall thickness plays a crucial role in determining their strength, pressure resistance, and suitability for various applications. There are multiple ways to represent pipe wall thickness, depending on industry standards and co ...

-

With less than a month remaining, the highly anticipated NEFTEGAZ 2025 exhibition is just around the corner! This prominent event, taking place in Moscow, Russia from April 14th to 17th, 2025, continues to solidify its position as one of the largest and mo ...

-

Since medium carbon steel is prone to cold cracks, hot cracks and other defects during welding, some special process measures need to be taken during welding to ensure normal welding. 1.Welding method Various arc welding methods can be used to weld medium ...

-

Carbon steel is a fundamental material in countless industries, prized for its strength, versatility, and cost-effectiveness. However, not all carbon steel is created equal. The amount of carbon present significantly influences its properties and applicati ...

-

Control valves are essential components in industrial process control, but they are prone to various issues that can impact performance and efficiency. Below are some common faults and their causes. 1.Valve Jamming and Blockage Jamming often occurs in newl ...

-

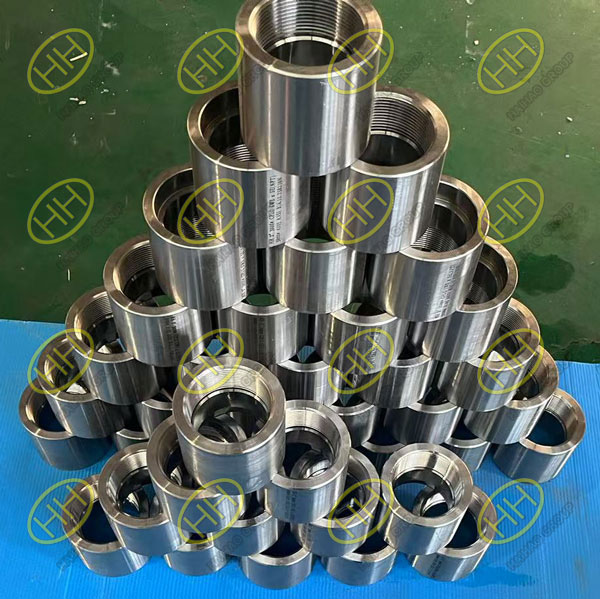

At Haihao Group, we pride ourselves on being a leading supplier of high-quality piping solutions tailored to meet the diverse needs of our clients worldwide. Today, we are excited to announce the availability of our ASME B16.11 standard 3000# ASTM A105 2&# ...

-

Haihao Group has successfully delivered a significant order of high-quality pipe fittings to a client in Singapore, showcasing our expertise in manufacturing and supplying products made from ASTM A350 GR. LF2 CL1 material. This delivery underscores our com ...

-

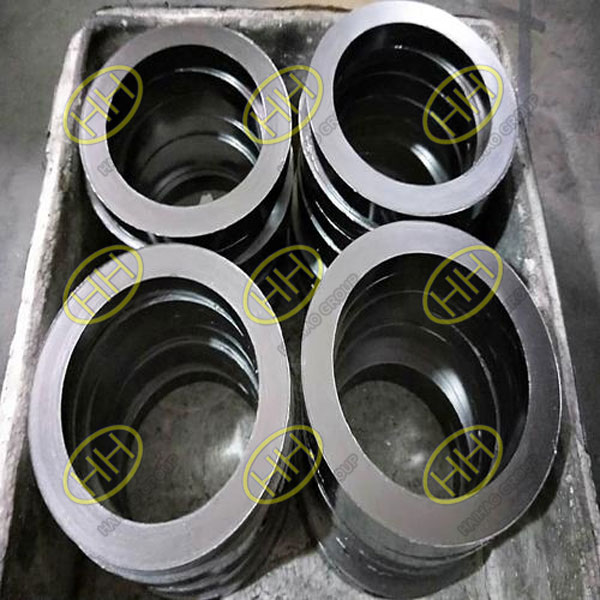

The IX Seal Ring is a high-performance metal-to-metal sealing component used in compact flanges (EN ISO 27509, API 6A). It is widely applied in high-pressure, high-temperature, and subsea environments, providing a secure and leak-proof connection. Shape an ...

-

A 45° socket weld latrolet is a specialized branch connection fitting designed to create a 45-degree outlet from a run pipe. It belongs to the olet family and is widely used in high-pressure and high-temperature piping systems. 45° Socket Weld Latrolets Pr ...

-

Positive Material Identification (PMI) is a crucial testing method used in the metal industry to verify the chemical composition of materials. PMI spectral analysis utilizes advanced spectroscopy techniques to accurately determine the elements present in m ...

-

Penetrant testing (PT) is a widely-used non-destructive testing method for detecting surface defects. There are various ways to classify penetrant testing based on different parameters. Below are the main classifications of penetrant testing: penetrant tes ...

-

Low-temperature pressure vessels operate under extreme conditions where thermal stress, material brittleness, and structural integrity are critical concerns. To ensure safety, reliability, and long-term performance, specific structural design principles mu ...

-

A mitre elbow is a type of pipe fitting that is used to change the direction of a pipeline. Unlike standard elbows, which are typically a single curved segment, a mitre elbow is made up of multiple straight segments (or “legs”) connected at a s ...