-

Oxidation and decarburization When steel is heated, there is a layer of brittle iron scale on the surface is called oxidation; decarburization refers to the phenomenon that the carbon content on the surface decreases. Oxidation and decarburization will red ...

-

Forging heat treatment process regulations (process cards) and heat treatment forging schedules are necessary process documents for guiding heat treatment production. In addition, there should be temporary process notices, heat treatment process codes, hea ...

-

Why should we have heat treatment on steel pipes? What are the main types of steel pipes’ heat treatment process? Heat treatment is one of the important processes in the production process of steel pipes. It plays an important role in exploring poten ...

-

Normalizing is a heat treatment process in which steel parts are heated to 30-50 ℃ above the critical temperature and cooled in static air after holding for appropriate time. The main purpose of normalizing is to refine the microstructure, improve the prop ...

-

The purpose of heat treatment of forgings after forging is to adjust the hardness of the forgings and improve the cutting performance; eliminate the internal stress after forging; refine and uniform the coarse grains during the forging process to prepare t ...

-

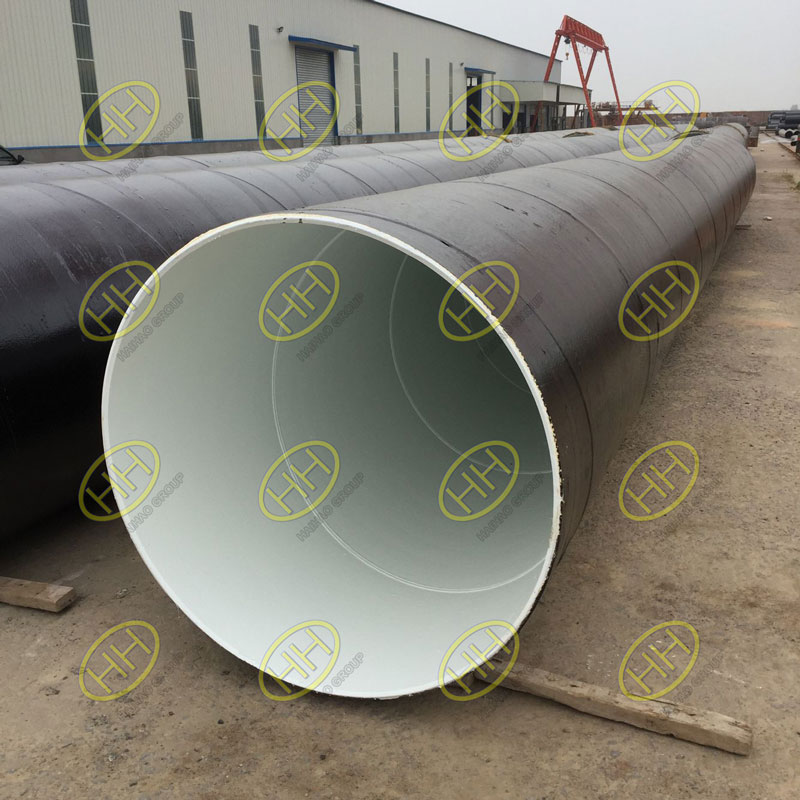

In China,3PE anticorrosive steel pipes have been applied in oil and gas systems,nearly 4,000 kilometers of the national key project West-East Gas Pipeline have used 3PE anti-corrosion steel pipes. We have also exported a lot of 3PE coated steel pipes to ma ...

-

For the steel water transmission pipes and fittings,the coatings are necessary to use in order to prolong the service life of products.The often used standard is AWWA standard.There are several coating types for steel pipes and fittings under this standard ...

-

Sometimes clients ask for the coal tar enamel coating or lining for the pipeline.We all know that coating or lining could protect the pipeline from corrosion and expand the service life.But how does it works? The coal tar pitch, which forms the basis for t ...

-

Global trends in pipeline technology and pipeline coatings are in part dictated by where the oil and gas reserves are located. These reserves are becoming increasingly difficult to find. Producers are looking further afield and often find the reserves are ...

-

Corrosion of pipe fittings refers to the degradation and destruction of metal materials caused by the chemical and electrochemical action between the metal material surface and the environmental medium. In petroleum pipelines, common corrosion is mainly ca ...

-

Butt weld fittings general A pipe fitting is defined as a part used in a piping system, for changing direction, branching or for change of pipe diameter, and which is mechanically joined to the system. There are many different types of fittings and they ar ...

-

Malaysian FPSO provider Yinson has contracted TMC Compressors to deliver a marine compressed air system to FPSO Anna Nery bound for the Marlim 2 oil field in the Campos Basin offshore Brazil. TMC said on Monday that the compressed air system would consist ...

-

Reducer is one of the chemical pipe fittings, which is used for the connection of two different pipe diameters. It is also divided into concentric reducer and eccentric reducer. Reducer materials include stainless steel reducer, alloy steel, reducer carbon ...

-

The market for floating production, storage and offloading (FPSO) vessels has exploded over the last few years, as the Oil & Gas industry has grown more dependent on ultra-deepwater offshore activity. As Wood Group explained in a sector-wide report: &# ...

-

A182 stainless steel forged fittings have good mechanical properties, less impurity and long service life, which are the top class among pipe fittings. Even in the harsh environment, they can also complete their missions very well. ASTM A182 cover stainles ...

-

Alloy 32750 (UNS S32750) is a super duplex stainless steel supplied in the solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of both austenitic and ferritic grades. The higher chromium, molybdenum and nitroge ...

-

F65 in ASTM a694 is carbon steel forging. The full name of A694 is ASTM A694. It is the forging of carbon steel and alloy steel pipe flange, fittings, valves and parts for high pressure transmission equipment. The grades of ASTM a694 are:F42,F46,F48,F50,F5 ...

-

LSAW submerged-arc longitudinal welded pipe (DSAW | Double Submerged arc welded):Tubular product having one or two longitudinal seams produced by submerged-arc welding. Specification Acc to API5L /ISO 3183 Quality Level: PSL1 and PSL2 Grade: Gr.B/BR/BN/BQ/ ...

-

Precision steel pipe is a kind of high precision steel pipe material which is processed by cold drawing or hot rolling. The precision steel pipe has high dimensional precision and high surface finish. After heat treatment, there is no oxide film on the inn ...

-

General precision pipe‘s production technology can be divided into cold drawing and hot rolling. The production process of cold rolled precision pipe is generally more complicated than that of hot rolled. The pipe billet should be rolled in three rol ...