-

Epoxy coal tar pitch anti-corrosion coating is composed of two main components of epoxy and coal tar pitch. It is a two-component coating of A (epoxy) and B (curing agent). It has excellent adhesion, toughness, moisture resistance, water resistance and che ...

-

Plastic lined steel pipe, with galvanized seamless steel pipe and welded steel pipe as the base pipe, is lined with food grade polyethylene (PE) pipe with the same diameter as the galvanized pipe after the welding reinforcement is removed from the inner wa ...

-

The method of removing oxide scale and rust from steel surface by acid solution is called acid pickling. Iron oxides (Fe3O4, Fe2O3, FeO, etc.), such as oxide scales and rust, react with acid solutions to form salts dissolved in acid solutions and are remov ...

-

When the surrounding medium and atmosphere cause the surface layer of the deformed body to dissolve and form a brittle phase with the metal substrate of the forging, the deformed object will be in a brittle state. For example, titanium can absorb hydrogen ...

-

The forging product inspection procedure is as follows: ① All forgings should be scrubbed before acceptance of the finished product. ② Before the forging finished product is submitted for inspection, the batch number,material,condition, specification,heat ...

-

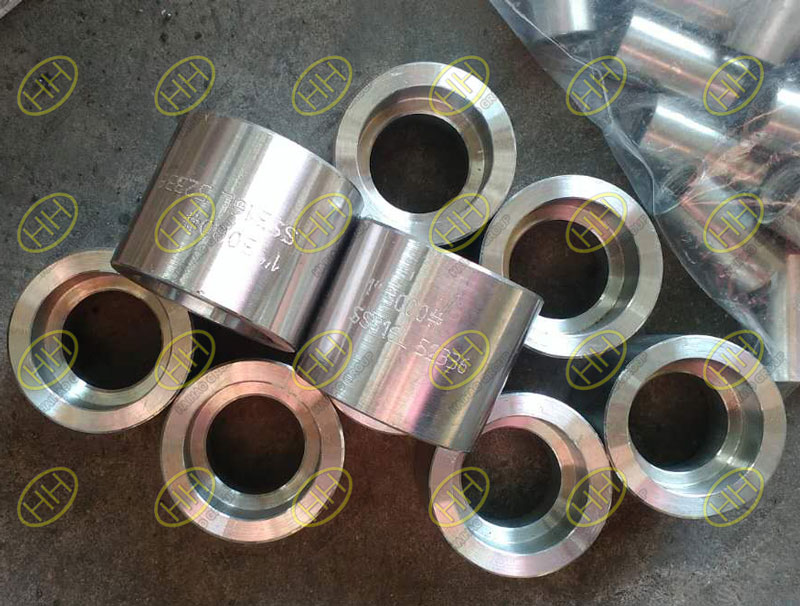

The cold forging of the flange is a small change in the size of the flange during low temperature casting. Casting below 700 ℃, the scale formation is small, and the surface has no decarburization. Therefore, as long as the deformation energy is within the ...

-

There are various connecting types for the steel pipes,pipe fittings and flanges: socket weld,butt weld,threaded and so on.Socket welding and butt welding are the quite popular of those.However,you might be confused about which one would be best for your p ...

-

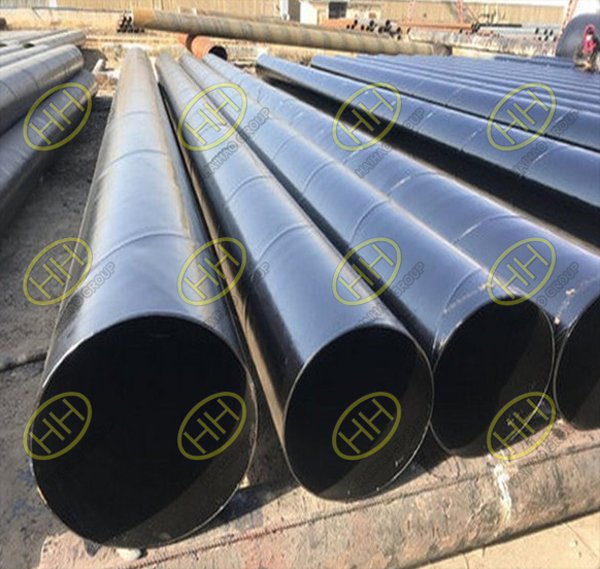

Steel pipe is a kind of hollow long steel, which is widely used as the pipeline for conveying fluid, such as oil, natural gas, water, gas, steam, etc. According to the production process, it can be divided into seamless steel pipe and welded steel pipe. Wh ...

-

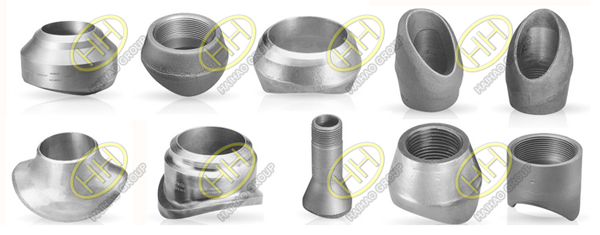

Olets are also called branch connections. Olet fittings are a family of forged products used to make 45 or 90 degrees integrally reinforced branch connections (deviations) from a run pipe (also called, header pipe) to a branch pipe (outlet pipe). The commo ...

-

After the double-sided submerged arc welded pipe(DSAW pipe) is rusted, the surface of the steel is mainly polished by using a wire brush or the like, and the cleaning and preheating of the spiral pipe can remove the loose or raised scale, rust, welding sla ...

-

In recent years, with the development of the national economy, thick-walled LSAW steel pipe have been increasingly used in offshore platforms, high-temperature and high-pressure vessels, and wind power pipe piles. The production of such steel pipes general ...

-

The main types of LSAW steel pipes for automobiles include automobile automobile silencer pipes, transmission shaft pipes, thrust pipes, condenser pipes, exhaust pipes, steering shaft pipes, and shock absorber oil storage pipes. The LSAW steel valve plate ...

-

In the last article,we learned some standards of the steel pipe.All these requirements can be met by selecting a pipe made to an appropriate standard e.g. ASTM or API Standard. API 5L : Line Pipe In the oil and natural gas industries, steel pipe used to co ...

-

As a professional pipe supplier,we supply steel pipes in different standards,let’s see the different between them.All these requirements can be met by selecting a pipe made to an appropriate standard e.g. ASTM or API Standard. ASTM A-53 Pipe, Steel, ...

-

The large-size seamless pipe forming technology mainly includes: hot spinning method, hot extrusion method, hot piercing rolling method, hot pushing and expanding diameter method. The details as follows: 1.Hot spinning method It is to fix the flat blank or ...

-

Introduction of elbow: The elbow is used more than any other pipe fittings. It provides flexibility to change the pipe direction. Elbow mainly available in two standard types 90° and 45°. However, you can manufacture elbow in any other degree or you can cu ...

-

How to make a stainless steel tee? Prepare a stainless steel tube blank with a plastic film on its surface; Extrusion of the stainless steel tube blank of the product to obtain a semi-finished product of the stainless steel tee; Solid solution treatment, s ...

-

There are two mold process of stainless steel tee,which are hydraulic bulging,hot press forming.(Forming process of stainless steel tee) Hydraulic bulging of stainless steel tee The hydraulic bulging of the stainless steel tee is a forming process for expa ...

-

Stainless steel tee is a chemical pipe fitting with three ports, one inlet and two outlets; or two inlets and one outlet. It has T-shaped and Y-shaped shapes, has equal diameter nozzles, and has different diameter nozzles. At the same or different pipeline ...

-

The seamless stainless steel pipe is a long steel bar with a hollow section and seamless joints. The thicker the wall thickness of a stainless steel pipe is, the higher its economical efficiency and practicality, and the thinner the wall thickness, the gre ...