-

The latest process of removing burr for stainless steel plate is electrolytic polishing, which requires a complete set of electrolytic polishing equipment for production, such as power supply, rectifier, polishing tank, workpiece hanger, heating facility, ...

-

In the pipeline industry,the welding is very important in the manufacturing of piping goods.SMAW is one of the important welding methods. SMAW otherwise stick welding is the short term of the Shielded Metal Arc Welding.The term stick means the electrode, a ...

-

GTAW, also known as tungsten inert gas (TIG) welding, is a type of arc welding which produces the weld using a non-consumable tungsten electrode. Inert gases such as argon or helium are used to protect the area being welded from contamination and most, alt ...

-

Millions of miles of pipelines are used to transmit drinking water around the world. These pipelines must have good corrosion resistance to water itself, soil chemicals and treatment chemicals, so as to ensure adequate service life and provide sanitary dri ...

-

Stainless steel is one important material used in piping projects,especially in some easily rusty environment.Because the stainless steel doesn’t rust easily.Why? Stainless steel remains stainless, or does not rust, because of the interaction between ...

-

In the last article we introduced what is alloy steel pipe,today i’ll tell you how to get high quality alloy steel pipes? The biggest advantages of alloy steel pipe Can be 100% recycled, environmentally friendly, energy-saving, resource conservation, ...

-

Alloy steel pipes are hollow pipe with round cross section for the conveyance of products. The products include fluids, gas, pellets, powders and more. The word pipe is used as distinguished from tube to apply to tubular products of dimensions commonly use ...

-

A threadolet (threaded outlet) is the same basic design as a “weldolet“. However the main difference is the fitting has a female threaded connection to mate to the branch connection. This makes a 90° branch and comes in full size or reducing fo ...

-

Spectacle flange consist of a connected ring (spacer) and a plate (spade). Spectacle blinds are generally applied to permanently separating pipe systems,or just to connect with each other.A spectacle blind is a steel plate cut into two discs of a certain t ...

-

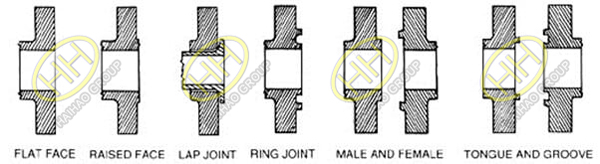

To answer this question, you have to learn about different type of flange faces. Here in the image, you can see the different types of flange faces. Flat Face (FF) Raised Face (RF) Lap Joint Ring Joint (RTJ) Male and Female types And Tongue and groove (T& ...

-

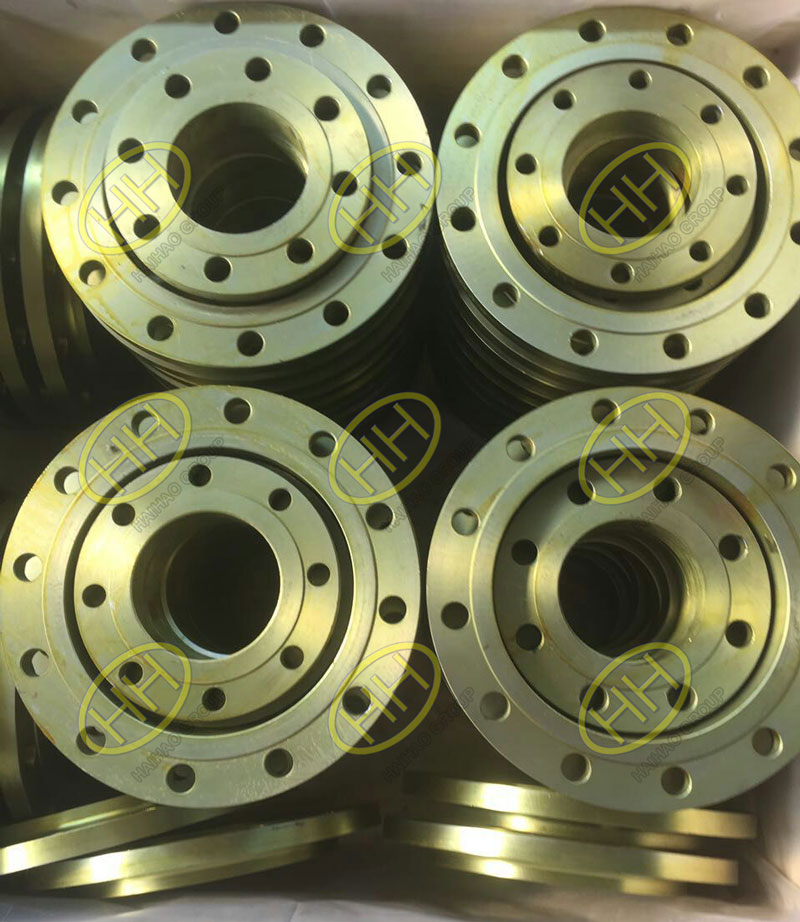

In the last article,we introduced the main functions of the slip on flange in detail,so today we will focus on the application characteristics of the slip on flange. The slip on flange not only saves space and weight, but also ensures that the joint will n ...

-

Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16 inch for slip on pipe flanges fewer than 400#. For slip on pipe flanges of 400# and up, the standa ...

-

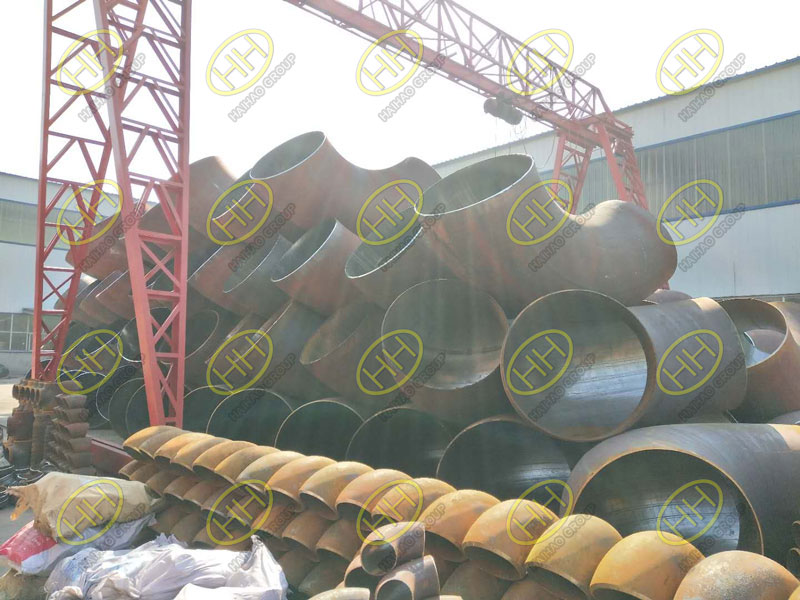

The stamping and welding elbow, it is the use of the same material as the pipe material plate with stamping die stamping into a half ring elbow, and then the two half ring elbow group welding forming. Because of its good comprehensive performance, it is wi ...

-

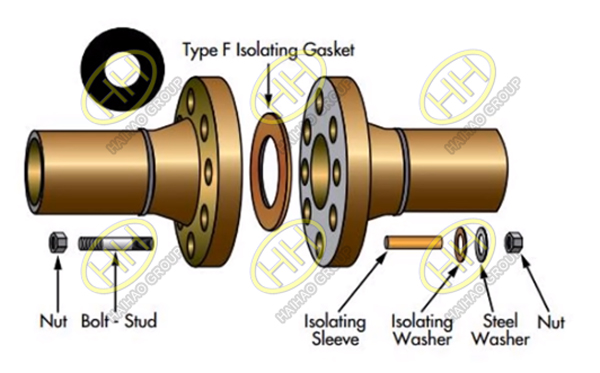

The isolation gasket kit is consist of insulating gasket, insulation sleeve,plated steel washers and insulating washers. These components are manufactured in special materials with proper chemical stability, low water absorption, and dielectric properties, ...

-

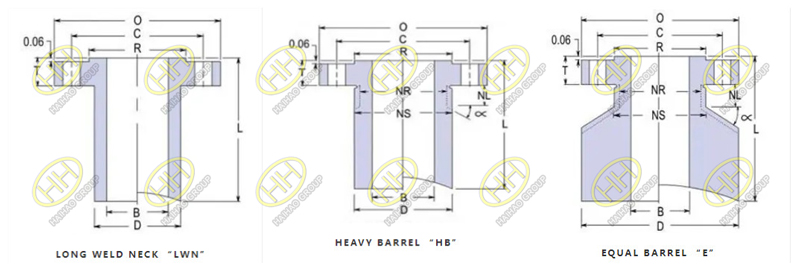

A long neck flange (LWN) and a welding neck flange have similar features, however, a long neck flange has a slightly longer neck. Long neck flanges on columns and barrels are used as nozzles in many industrial businesses. Equal LWN barrels and heavy barrel ...

-

A stainless steel elliptical head is a product used to plug stainless steel pipes. It is a product used as a container after the pipe has reached its end or two elliptical heads are welded to the two ends of a round pipe. According to the different geometr ...

-

The insulation gasket kit is a specially designed gasket package that use to prevent galvanic corrosion of flange face in a piping system when the material of connecting flanges is different. Here, in the image, you can see the complete kit of insulation g ...

-

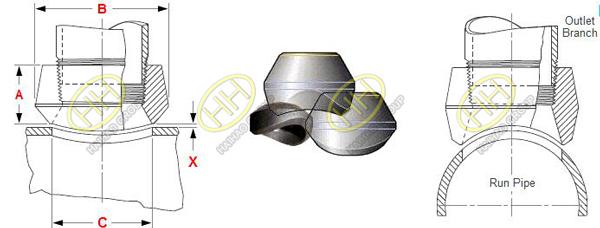

Olet fittings are a family of forged products used to make 45 or 90 degrees integrally reinforced branch connections (deviations) from a run pipe (also called header pipe) to a branch pipe (outlet pipe). The common types of branch fittings are Weldolet, Th ...

-

The nipple is a kind of fitting commonly used in industrial pipeline connection.There are common screw nipples, which are divided into double head outer thread, single head outer thread and flat head outer thread. In addition, there are also nipples connec ...

-

In piping, a gasket is a sealing material placed between the connecting flanges to form a static seal that maintains a leak proof seal under all operating conditions.Different types of gaskets are used to realize leak proof sealing between pipeline flanges ...