-

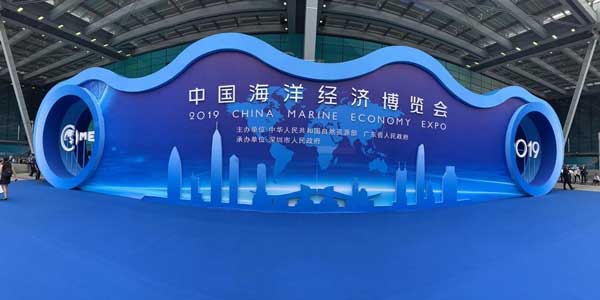

China Marine Economy Expo, the only national marine economy exhibition in China, is an important window to show the achievements of China’s marine economy development. With the theme of “enabling scientific innovation and sharing deep blue̶ ...

-

On October 30, the steel pipes ordered by Dutch customers in Haihao were delivered. This is the 16th batch of goods, and 15 batches of goods have been sent to projects in the Netherlands before. Last year, the Netherlands signed a contract with Haihao to p ...

-

We have received an order from an Italian customer, who needs FBE coated pipe bends. The product details are as follows: DN48″x 0.625″ (1219.2×15.9mm) API 5L, Gr. B, PSL-1, SAW, pipe bend 22.5degr., radius 5D, bevelled, SCH ASME B36.10M, E ...

-

FBE is the abbreviation of “Fusion Bonded Epoxy“. There are two types of FBE coating: single layer and double layer. FBE coating generally refers to a single-layer fusion-bonded epoxy coating. The single-layer FBE coating uses a special fusion- ...

-

In June, a customer in Vietnam sent an inquiry to Haihao. He wanted to order a batch of steel pipes with an order quantity of 10 tons. The products would be used for a local project in Vietnam. After receiving the inquiry, Haihao Group responded positively ...

-

As a large-scale foreign trade enterprise, Haihao Group has developed rapidly relying on the policy of the Belt and Road, and its performance has improved rapidly in recent years. Especially in the Middle East, Southeast Asia and other regions, a large num ...

-

The products of the order are fixedmarine platform for oil and gas project closed to the Arctic Circle.The subsea engineering project is more serious, and the requirements for product materials are more stringent. Our company department also attaches great ...

-

Since our Russia’s petroleum cracking pipe and fittings order confirmed on August, it’s pasted two months. Our client has pushed us for many times for the delivery time. But this order it’s customized products. It’s contains: 2 piec ...

-

As different countries and regions adopt different product standards, as a foreign trade supplier, manufacturers should be able to produce products of various standards. With more than 40 years of prodauction and operation experience in the pipe fitting in ...

-

The construction environment of oil pipeline is various, and environmental factors must be fully considered when constructing the pipeline. Among all kinds of construction environment, desert is undoubtedly a difficult construction environment. The long-te ...

-

Refinery refers to a factory that produces diesel oil, gasoline, kerosene, lubricating oil, petroleum coke, asphalt, ethylene and other products from the crude oil extracted from the formation through distillation, catalysis, cracking, cracking, hydrofinin ...

-

Refineries play a very important role in the application of petroleum products. Generally speaking, there are three types of refineries: Fuel type refinery. Clean fuel is produced, and some clean fuel refineries also produce lubricating oil Oil chemical c ...

-

The oil pipeline is composed of oil pipes and their accessories, and is equipped with corresponding oil pump units according to the requirements of the process flow. It is designed and installed into a complete pipeline system to complete the oil receiving ...

-

Due to the harsh offshore construction environment and fierce market competition,the requirements for the quality,specification,material,price,supply cycle and after-sales service of steel pipes are becoming higher and higher.In the course of more than 40 ...

-

Haihao Group has recently participated in the supply of submarine pipeline projects and has rich experience in cooperating with this type of project. Due to different operating environment,submarine pipelines generally vary in diameter from 3 inches (76 mm ...

-

People have begun to search oil resources in shallow seas since 1950s.With the development of mining technology,the mining is no longer limited to shallow seas and the depth of mining is getting deeper and deeper.But there is always a question here:how do ...

-

About 20 days ago, one of our Canadian customers placed an ordered for 3D bend. The details are: 45°3D seamless bend, the size is 24″, the wall thickness is SCH60, the material is ASTM A312 316L, and the standard is ASME B16.9. After more than ten da ...

-

One month ago, we received an inquiry about Alloy 800 material from Russia. This inquiry including 3 items totally: 2 pieces 90 degree 610mm seamless elbow, one length 610x1500mm seamless pipe, one length 560x500mm pipe, it‘s a small quantity. As per ...

-

Sometimes we receive some orders about UNS S32750 material. It’s one kind of Super duplex stainless steel. This material is made of 25% chromium, 4% molybdenum and 7% nickel. It has strong strength and corrosion resistance, and is mainly used in che ...

-

Today our Singapore clients order it’s finished. This order including duplex 2205(UNS S31803) and super duplex 2507(UNS S32750) pipe, fittings and flanges. As for this order, clients not only need fast delivery time 20 days but also the 100% PMI when ...