-

Many problems often occur when forgings are heat treated and quenched, such as: oxidation and decarburization, overheating and overburning, deformation and cracking, and insufficient hardness. These problems will affect the size of the product, reduce the ...

-

The ideal solution should be a combination of excellent corrosion protection and simple construction procedures, and should be suitable for all sizes and shapes of flanges, and easy to operate bolts during maintenance. As a professional flange supplier of ...

-

The integrity of flange connections is critical to the fluid piping system. Whether it is the piping system transporting chemical media or the water supply pipeline, the leakage of flange connection will cause serious environmental and economic impacts,and ...

-

As we all know,there are many types of pipeline corrosion.Different types of coatings are designed to mitigate corrosion in different environments, including plant-manufactured systems and construction site tapes.Read this article you will know several mai ...

-

Novel coronavirus (2019-nCoV) disease affects all parts of the country from all walks of life in China. For us steel foreign trader, traffic control, resume work delay , many direct and indirect effects will cause the order delivery delay, no quotation , ...

-

In the last article we learned what is pipeline corrosion and its process,you must want to avoid it.As the saying goes, “know the enemy and know yourself, and you can fight a hundred battles with no danger of defeat”,the first thing you must do ...

-

Pipeline corrosion refers to the deterioration of pipeline materials and related systems due to the interaction with the working environment.It affects pipes and fittings made of metal and non-metal.Pipeline corrosion can related catastrophic failures that ...

-

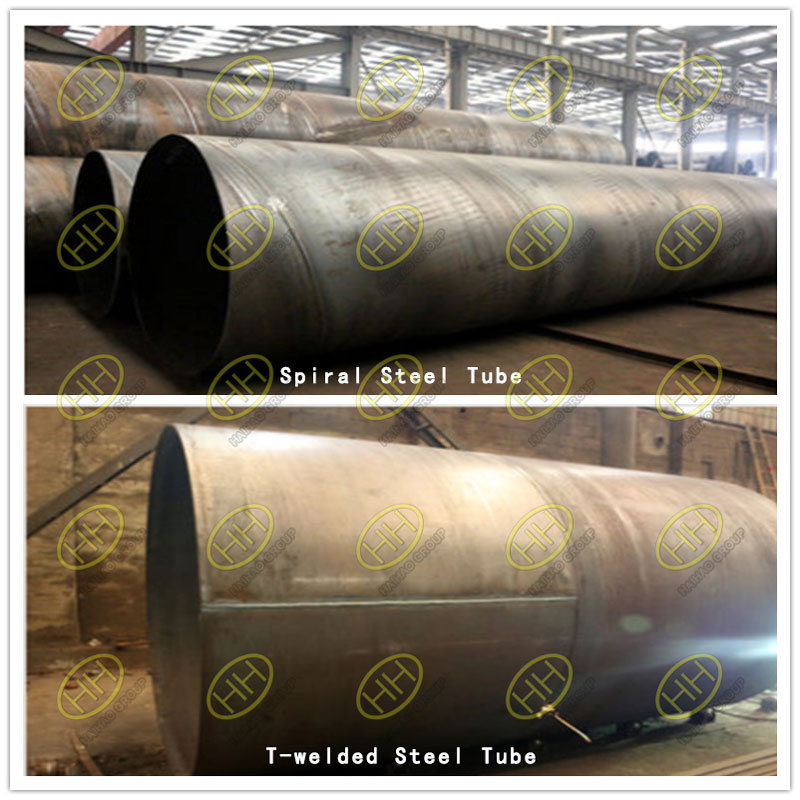

Spiral steel tube and T-welded steel tube are basically the same raw materials used for steel pipe, but they are very different in the production process. Spiral steel pipe: the spiral seam steel pipe is made by automatic double silk and double submerged a ...

-

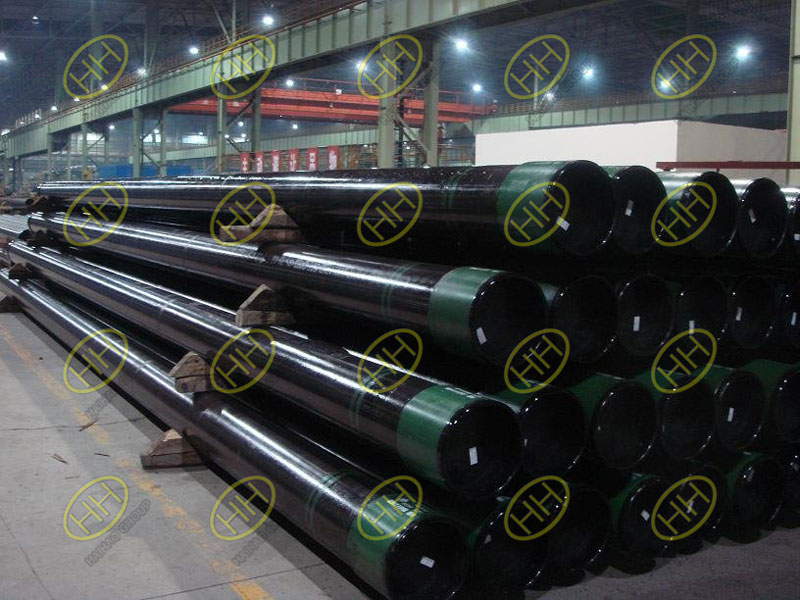

What’s the casing pipe? The shape of the casing section is round, in large diameter pipes and is inserted into the oil well, fixed with cement to protect other equipment that is mostly made of iron and steel. The oil well must be designed to withstan ...

-

Seamless pipes and welded pipes are widely used piping products.Seamless pipes means the pipes have no welding or seam,but welded pipes have welds on the surface.Now i’ll tell you the difference between them,let’s see: Seamless pipes don’ ...

-

Spiral wound gasket is components of metallic strip,filler,and guide ring (outer and inner ring). Strapping material could be stainless 304,304L,316,316L or other materials as request. Filling Materials are flexible graphite,or PTFF,filling thickness usual ...

-

Flange gaskets are the important part in the piping system,which are used to connect flanges and play a sealing role.If the flange gaskets selection is not suitable,so that the pipeline often damaged will cause economic losses to the enterprise production, ...

-

EN10216-1 is the European Union standard for seamless steel pipes. Applications EN10216-1 seamless steel pipe is mainly used for boiler water pipe, smoke pipe, superheater pipe, air preheating pipe, etc. It is also utilized to produce pipeline, equipment, ...

-

The seamless carbon steel pipe is formed by perforating a steel ingot or a solid tube blank, and then hot rolled, cold rolled or cold drawn. Seamless carbon steel pipe plays an important role in steel pipe industry. The raw material of the seamless carbon ...

-

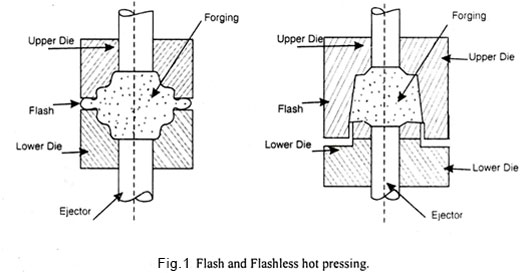

Closed die forging is also known as impression die forging.It is a forging process,and it involves two or more dies that contain a precut profile of the desired component.Forging in which the material is fully constrained in the cavity created by the upper ...

-

Open die forging is an important technique for many types of forging manufacturing.It allows rough and finishing shaping of metal, most commonly steel and steel alloys. It takes heated metal and compresses it between two dies. The metal is worked at temper ...

-

Warm forging is performed with the workpiece heated to a range that is generally above the work hardening temperature and below the temperature at which scale forms. The process fills the niche between the closer tolerance, but sometimes expensive cold for ...

-

Cold forging is one variation of the forging metal-shaping process that involves forming or shaping metal parts through a process of applying powerful, localized compressive forces. Cold forging is carried out with the metal generally kept at or slightly a ...

-

Hot forging entails the heating of a workpiece to about 75% of its melting temperature. This allows for the flow stress and energy required to form the metal to lower,effectively increasing the rate of production (or strain rate). Hot forging aids in makin ...

-

Press forging may be defined as the process of shaping a metal that is placed between two dies by applying mechanical pressure or hydraulic pressure. Press forging is usually done on a forge press – a machine that applies gradual pressure on the forg ...