-

A pipeline coating is a cost effective and viable solution to maintain pipelines’ integrity. Coatings are typically applied to counter the negative effects of corrosion on pipeline operation, capacity and costs. Pipeline coating is one of the most re ...

-

What is A234 WPB? A234 WPB is an American standard pipe fitting material. Used for carbon steel elbow, tee, reducing pipe, pipe cap, elbow and other products. How is A234 WPB made up? The chemical composition of A234WPB is C≤0.03Mn= 0.29-1.06P ≤ 0.05s ≤0 ...

-

The prevention of cold cracks is mainly caused by reducing the diffusion hydrogen content, improving the structure, and reducing the welding stress. Specific measures are: 1.Preheating before welding and slow cooling after welding. This not only improves t ...

-

Perhaps you have encountered this situation before: after a long wait, a pile of goods with broken packaging have been sent to you across the sea. You try to persuade yourself to accept these products, but after inspection, there are many unqualified produ ...

-

A182 F51 is a duplex stainless steel made of 21% chromium,2.5% molybdenum and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness and good integral and local stress corrosion resistance. The yield strength of duplex stainless steel is t ...

-

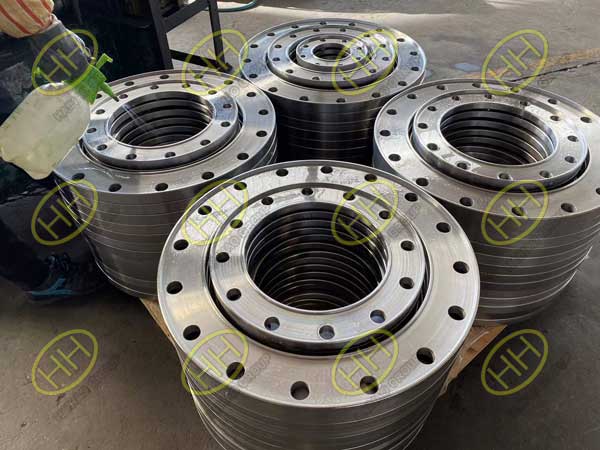

After more than one month of production, the flange production of Canadian customers was completed.After inspection, the size meets the requirements, and they are ready to be sent to Canada. One day about two months ago, a Canadian customer sent me an inqu ...

-

The hot dip galvanized pipe fittings for this batch of order include galvanized elbow, galvanized reducer, galvanized tee, galvanized pipe cap, etc. At the request of the customer in Indonesia, the pipe fittings were hot dip galvanized. The main purpose of ...

-

Recently we finished the order of customized forging products.It includes pipe and reducers with material ASTM A694 F65. ASTM A694 F65 FORGED PIPE ASTM A694 F65 FORGED PIPE Forging is a processing method that uses forging machinery to hammer or press the m ...

-

ANSI B36.19 contain stainless steel seamless steel pipes and welded steel pipes,ANSI B36.10 contain seamless steel pipes and welded steel pipes. The steel pipe data chart below can be used to find pipe sizes, diameters, wall thickness, working pressures an ...

-

Technological process: (1) Use grinding wheel cutting machine to cut the material, turn the end face and fillet R5. (2) The furnace temperature is (450 ± 10) ℃ and the holding time is 136min. (3) Die forging and die forging equipment is 6300kN friction pre ...

-

Let’s learn about the quality problems and solutions of forgings in quenching and cooling: Insufficient hardness and enough hardening depth: quenching cooling rate is low is forging quenching hardness is insufficient, the cause of the uneven hardness ...

-

According to different types of steel and process requirements, the following heat treatment methods are often used for forgings: annealing, normalizing, tempering, quenching and low temperature tempering, quenching and aging, etc.Let’s take a look a ...

-

About a month ago, I received an inquiry from a customer in Singapore, the main product is carbon steel flanges and pipe fittings. The products in the inquiry are as follows: Dimensions inspection of blind flange (1)WN flange RF, size: 1.1/2 “~18R ...

-

Today, the production of a batch of carbon steel pipe fittings has been completed. The quality test is qualified and they are all in line with the requirements. They have been smoothly shipped to Turkey. Elbow LR Seamless About two months ago, a customer f ...

-

Stamping elbow is a good elbow, which has been widely used and promoted in different fields and industries. The stamping elbow is formed by the same die as the pipe, and then the two half ring elbows are welded in batches. Due to the different welding stan ...

-

My Korean client Mr. Park inspected the order at our factory from May 25 to 31. During this period, I accompanied Mr. Park to carry out the inspection. We prepared a lot of inspection tools, some of which we bought new, and no customer or third party had a ...

-

Forging is a workpiece or blank obtained by forging and deforming a metal blank. The mechanical properties of metal billet can be changed by applying pressure to make it produce plastic deformation. The looseness of metal can be eliminated by forging. Hole ...

-

As a developing country, Serbia has witnessed rapid economic growth in recent years, which has been called “the tiger of the Balkans” by some people. All aspects need to be built of this country. WELD NECK FLANGES EN 1092-1 P235GH Electricity i ...

-

Tee is a pipe fitting and pipe connector, which is used in the branch pipe of main pipeline. There are two kinds of tee: equal tee and reducing tee. Named because the three ends can be connected to the pipe. Recently our factory produce some thick wall tee ...

-

The chemical polishing is a common polishing method for stainless steel products. Chemical polishing generally uses nitric acid or phosphoric acid and other oxidizing agent solution, under certain conditions, make the surface of stainless steel products ox ...