-

In addition to ASTM A923 C mentioned above, the customer also provided another pitting test method, namely ASTM G48 C. In order to better understand the difference between the two, I now introduce ASTM G48 C. Method C – Critical Pitting Temperature T ...

-

The ferrite experiment was introduced in the first part. The experiment went well, but the pitting experiment was more twists and turns. Initially, the customer provided two tests: ASTM A923 C or ASTM G48 C. First, I will introduce ASTM A923 C, then ASTM G ...

-

Since the customer has such high requirements on the corrosion resistance of the material, it is natural that we are required to do pitting experiments after the production of the product, so as to verify the real corrosion resistance of the product. About ...

-

In the last article, we mentioned that our technical staff advised the customer to use S32205 instead of S31803. To introduce the difference between the two, we first need to introduce the metallographic structure and corrosion resistance of dual-phase ste ...

-

In mid-April,a new customer from Indonesia came to me and asked me to quote for his order of duplex stainless steel, which included steel pipes, pipe fittings and flanges. How did the client find me? Because when he searched online related keywords such as ...

-

Hebei Haihao Group is a manufacture specialized in producing flange, pipe fittings and steel pipe. Seamless steel pipes are everywhere in our life. The manufacturing process of seamless steel tube begins with solid round billet. Then the billet is heated t ...

-

Hebei Haihao Group is a professional manufacturer of flanges and pipe fittings. We not only have strong technical force, can produce standard, non-standard and customized high, medium, low pressure various specifications, various series of pipe fittings fo ...

-

Haihao Group is committed to providing the best quality tees,which contain equal tee and reducing teem,according to different production method it can be divided into butt weld tee and forged tee. The main function of tee is to change the direction of the ...

-

As shown, part of the forgings produced for the Russian order and part of the pipe fittings are in production. The sudden outbreak of the Russia-Ukraine war disturbed the pattern of world trade. Trade related to the war, orders that are being negotiated, o ...

-

If shown, the steel pipes in the picture are a batch of pipeline steel pipe orders from old customers in Belarus that were completed a few days ago. This batch of steel pipe is used in the local project and has certain requirements for the product. Since w ...

-

In December, an old Brazilian customer ordered a batch of elbows that were different from the regular elbows in each order.The products were ASTM A234 WPB 90 degree long radius reducing elbows according to ASME B16.9 standard. This batch of pipe fittings h ...

-

Recently, our factory received a batch of orders for carbon steel 2D and 3D pipe bends, and produced a batch of 400NB thick elbows with high quality. At the request of the customer, the exterior is painted with anti-rust oil, the pallet is packaged, and re ...

-

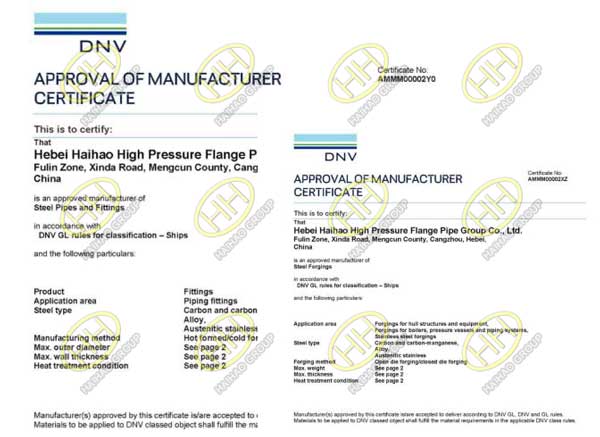

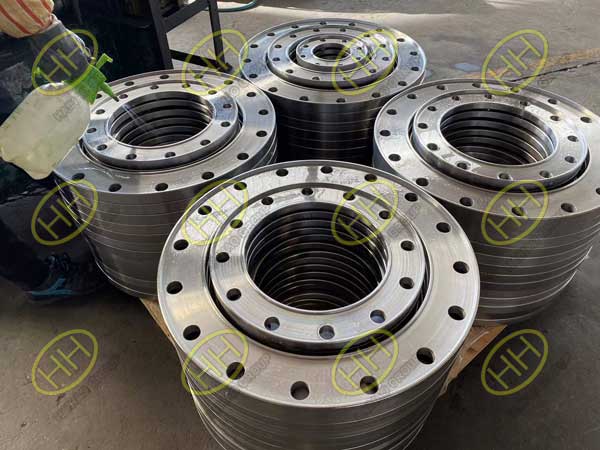

Recently, the carbon steel, alloy steel and stainless steel flange,pipe fittings produced by Hebei Haihao Group have obtained the certification of DNV and the relevant certificates approved and issued by the headquarters of DNV. This is another classificat ...

-

Last week we received an inquiry from a customer about plastic steel lined pipes. The details of the inquiry are: 2 “, 3 ” and 4″ with wall thickness of SCH40 and length of 6 meters. However, in the follow-up communication process, we lea ...

-

Yesterday we received an inquiry from a customer in Singapore for insulating joint s. Mainly including 1 “, 2 “, 6 “, 8 ” insulating joint s. But the customer did not provide the specific Material and pressure, but only the material ...

-

Pipeline products will be affected by the environment and media corrosion will cause serious consequences, pipe coating, lining and cladding are three commonly used pipeline anticorrosion methods, what is the difference between them? Pipe Coating The coati ...

-

A pipeline coating is a cost effective and viable solution to maintain pipelines’ integrity. Coatings are typically applied to counter the negative effects of corrosion on pipeline operation, capacity and costs. Pipeline coating is one of the most re ...

-

What is A234 WPB? A234 WPB is an American standard pipe fitting material. Used for carbon steel elbow, tee, reducing pipe, pipe cap, elbow and other products. How is A234 WPB made up? The chemical composition of A234WPB is C≤0.03Mn= 0.29-1.06P ≤ 0.05s ≤0 ...

-

The prevention of cold cracks is mainly caused by reducing the diffusion hydrogen content, improving the structure, and reducing the welding stress. Specific measures are: 1.Preheating before welding and slow cooling after welding. This not only improves t ...

-

Perhaps you have encountered this situation before: after a long wait, a pile of goods with broken packaging have been sent to you across the sea. You try to persuade yourself to accept these products, but after inspection, there are many unqualified produ ...